Clamping tool with cylinder

A cylinder and clamping technology, applied in the direction of clamping, positioning device, clamping device, etc., can solve the problems of insufficient machining accuracy, insufficient clamping strength, small clamping force, etc., to improve machining accuracy, wide application range, Vibration reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

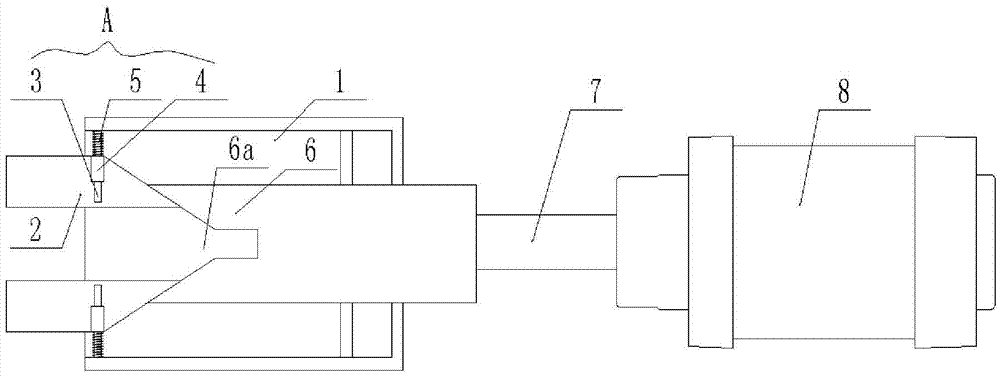

[0015] Such as figure 1 As shown, a clamping tool with a cylinder includes an installation cavity 1, and two clamping arms 2 facing oppositely are installed in the installation cavity 1, and the heads of the clamping arms 2 are respectively forward Stretch out the installation cavity 1, in which two reset guides A are installed facing each other, the reset guides A are respectively connected with one of the clamping arms 2, in the installation cavity The body 1 is provided with a clamping arm internal pressure rod 6, and the front end of the clamping arm internal pressure rod 6 is aligned with the tail of the clamping arm 2, that is, the tails of the two clamping arms 2 face toward the clamping arm. The direction of the internal pressure rod 6 of the holding arm gradually decreases from the outside to the inside. The front end of the internal pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com