A 3d printing device

A 3D printing and equipment technology, applied in the field of 3D printing, can solve the problems of printing material strength, performance degradation, failure to meet the required coloring degree, high pigment content ratio, etc., to achieve the effect of saving pigment consumption, uniform mixture, and fast coloring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

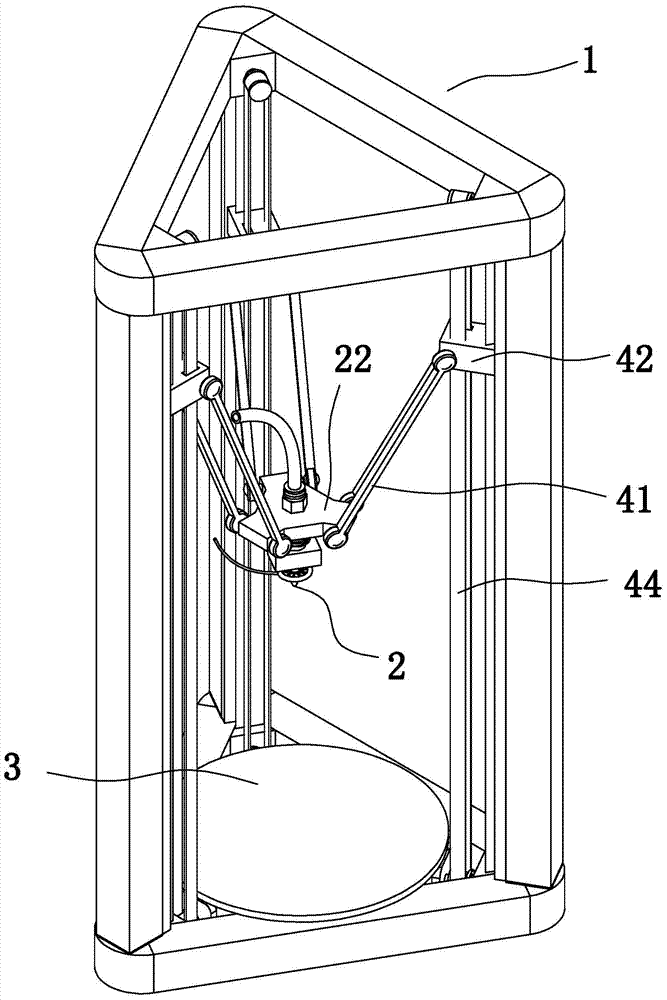

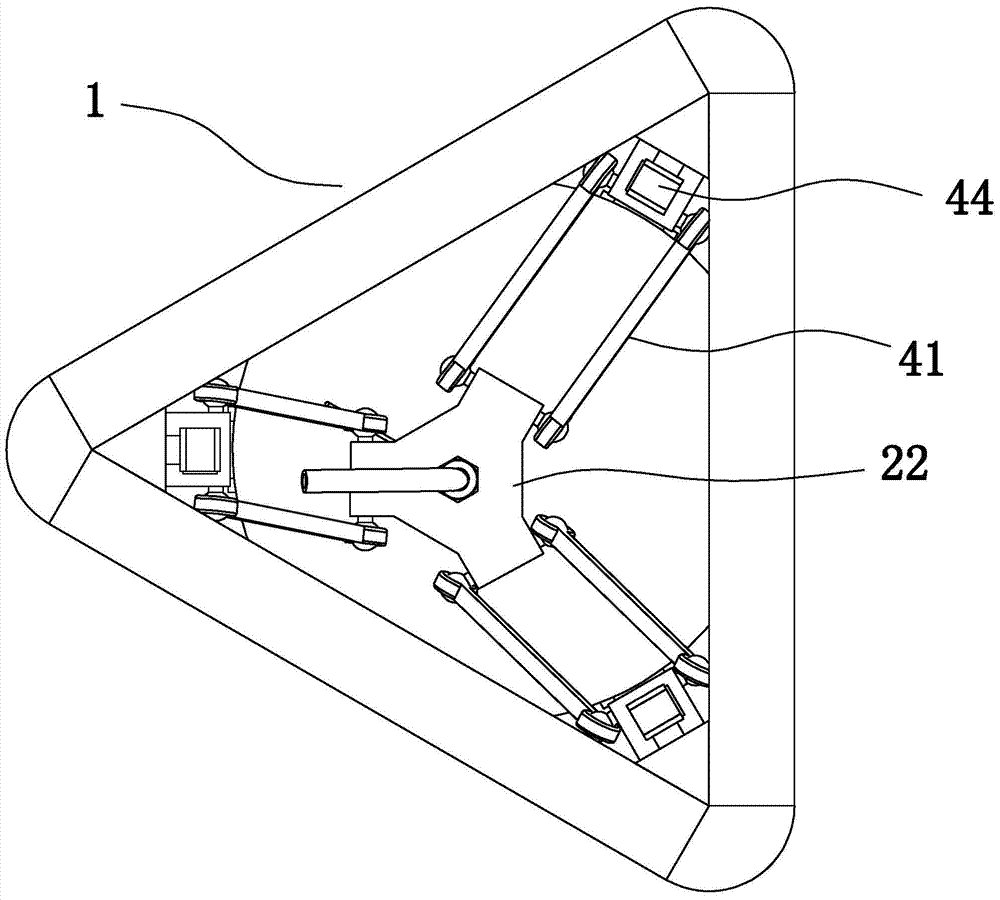

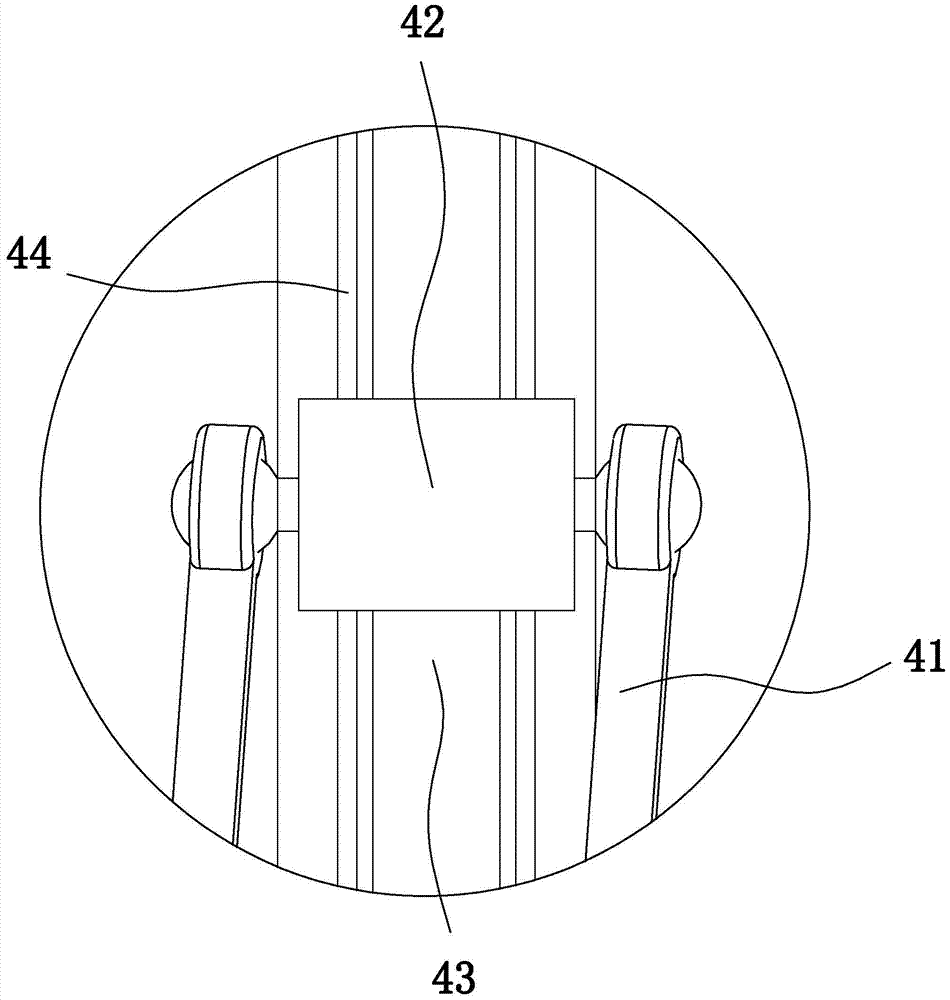

[0028] Embodiment 1: as Figure 1 to Figure 6 In the illustrated embodiment, a 3D printing device includes a main frame 1, a discharge print head 2, a forming printing table 3, and a print head for driving the discharge print head to move so as to change the position of the discharge print head Displacement adjustment mechanism, the discharge print head is provided with a print head feed end for inputting printing materials, the discharge print head is provided with a discharge channel 21 communicating with the print head feed end, and also includes a paint bucket 1. The delivery pump, the inlet of the delivery pump is connected to the paint bucket, and the outlet of the delivery pump is connected to the discharge channel. The discharge printing head is used to output printing materials (such as molten plastic) to the forming printing table, and the printing head displacement adjustment mechanism is used to adjust the relative position between the discharging printing head and...

Embodiment 2

[0033] Embodiment 2: the basic structure and implementation mode of this embodiment are the same as embodiment 1, and its difference is:

[0034] like Figure 7As shown in , the discharge channel is provided with a thermal insulation tube 23 coaxial with the discharge channel. The upper and lower ends of the thermal insulation tube are open. Thin material coloring channel 24 is formed between the wall and the channel wall of the discharge channel (that is, the inner wall of the discharge print head). The outlet of the coloring tube faces the outer wall of the heat-insulating tube, and a coloring check valve 521 is arranged at the outlet of the coloring tube. The passing direction of the coloring one-way valve is from the coloring pipe to the discharge channel, the highest point of the coloring port is lower than the highest point of the heat insulation cylinder, and the lowest point of the coloring port is higher than the lowest point of the heat insulation cylinder. The vert...

Embodiment 3

[0035] Embodiment 3: the basic structure and implementation mode of this embodiment are the same as embodiment 1, and its difference is:

[0036] like Figure 8 As shown in , the discharge printing head is provided with a metal heating block 25 that can be heated by electricity, and a part of the metal heating block extends into the discharge channel. This solution is suitable for solid raw materials, which are heated and melted after entering the discharge channel, and then printed and solidified. This solution is also applicable to the form of secondary heating, that is, in order to avoid the temperature drop too fast after the molten raw material enters the discharge channel, the metal heating block is used for secondary heating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com