Vehicle-mounted curved rail lubricant lateral spraying device

A technology of spraying device and lubricant, which is applied in the directions of rail lubrication, rail wetting/lubrication, transportation and packaging, etc., can solve the problems that the lubricant cannot lubricate and reduce wear, pollute the rail and the ballast bed, and waste the lubricant, etc. Achieve the effect of extending service life, reducing waste and reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

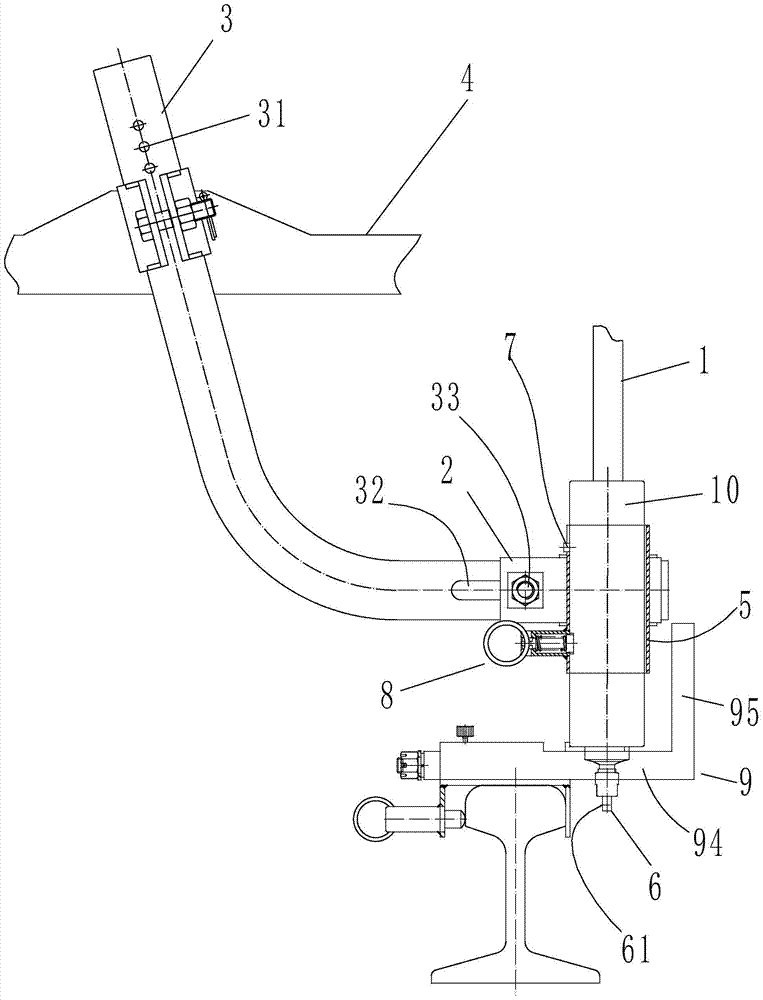

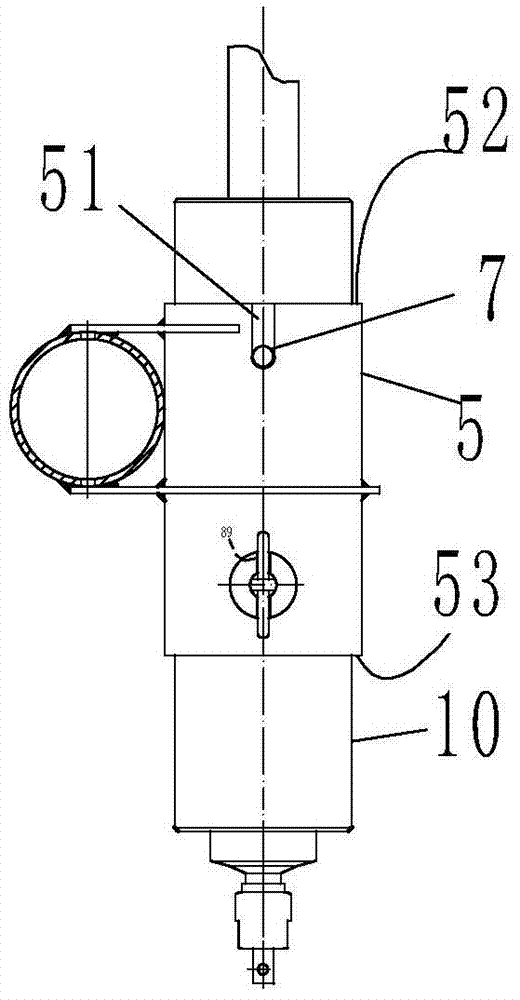

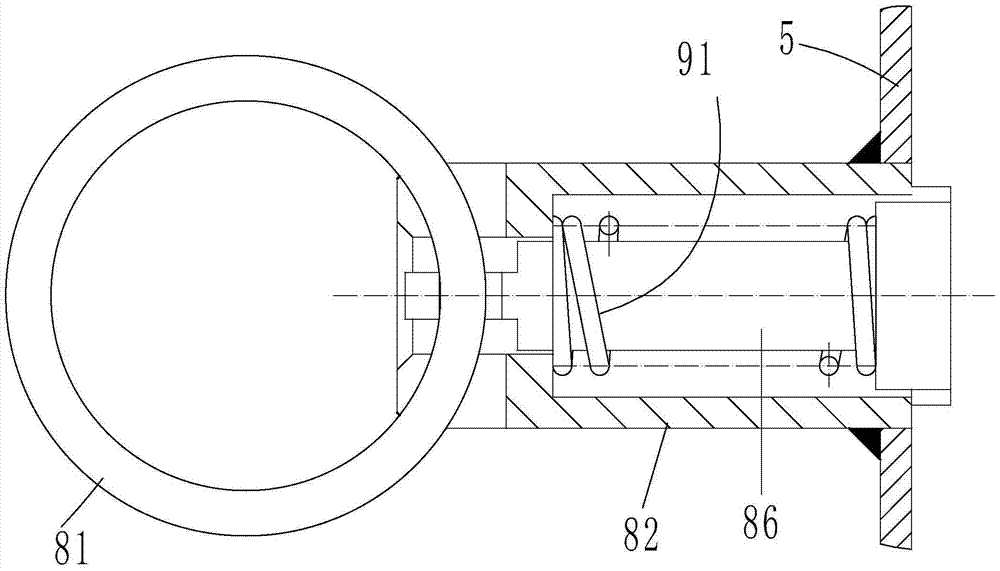

[0023] Such as Figure 1 to Figure 5 As shown, a vehicle-mounted curved rail lubricant lateral spraying device includes a height adjustment pipe 3, a snap ring 4, a horizontal adjustment pipe 2, an oil injection pipe 1, a top tightening structure 8, a wheel positioning structure 9, and a positioning sleeve 5 , positioning pin 7, side spray nozzle 6, the height adjustment pipe 3 is fixed on the axle box of the locomotive and vehicle, the height adjustment pipe 3 is an elbow, and the horizontal part of the elbow is provided with a horizontal adjustment near the end. Tube 2, the horizontal adjustment tube can adjust the axial position in the horizontal part of the elbow, the horizontal adjustment tube 2 is connected with the vertical positioning sleeve 5 of the vertically arranged round tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com