A layered circulating oil-water separator

An oil-water separator and oil-water separation technology, applied in chemical instruments and methods, multi-stage water/sewage treatment, flotation water/sewage treatment, etc., can solve complex and bulky structural design, affect ship load-bearing effect, maintenance difficulties, etc. Problems, to achieve the effect of convenient operation, reduce daily maintenance costs, and increase the separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

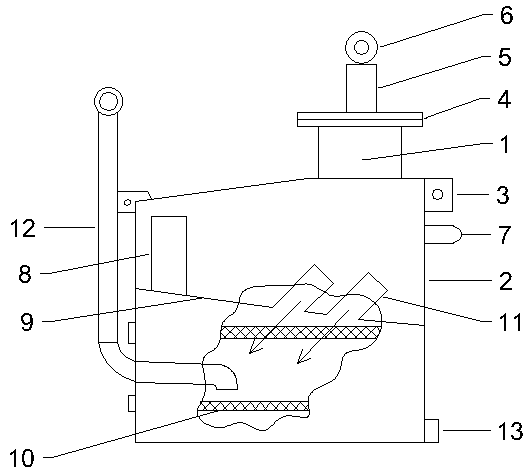

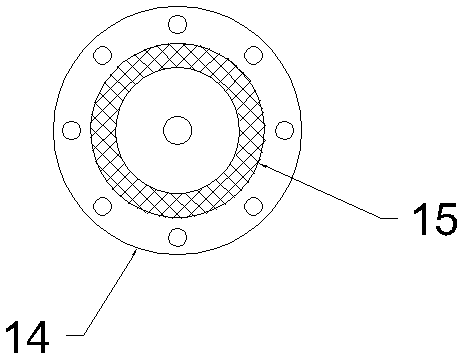

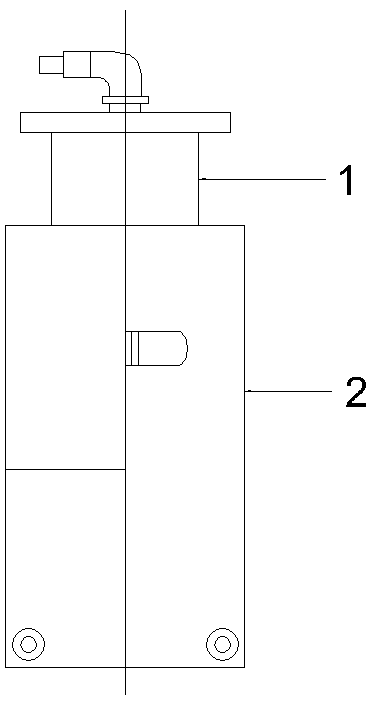

[0010] Below in conjunction with all accompanying drawings the present invention will be further described, and preferred embodiment of the present invention is: see appended figure 1 to attach image 3 , a layered circulating oil-water separator described in this embodiment includes an oil-collecting chamber 1 and an oil-water separation chamber 2, wherein a mounting bracket 3 is provided on the outside of the oil-water separation chamber 2, and a mounting bracket 3 is provided on the top side of the oil-water separation chamber 2. Outer slope plate, the other side of the top of the oil-water separation chamber 2 is provided with an oil collection chamber 1, the top of the oil collection chamber 1 is provided with a cleaning guide door 4 for the oil collection chamber, and the cleaning guide door 4 for the oil collection chamber is provided with a dirty oil discharge The pipe 5 and the dirty oil discharge pipe 5 are provided with a manual discharge valve 6, and the upper part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com