Shifting device and method for operating an automatic multi-speed transmission of a motor vehicle

A technology of multi-speed transmission and shifting device, which is applied in transmission control, mechanical equipment, components with teeth, etc., can solve the problems of intensive cost and complicated layout, achieve simple structure and improve the effect of braking effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

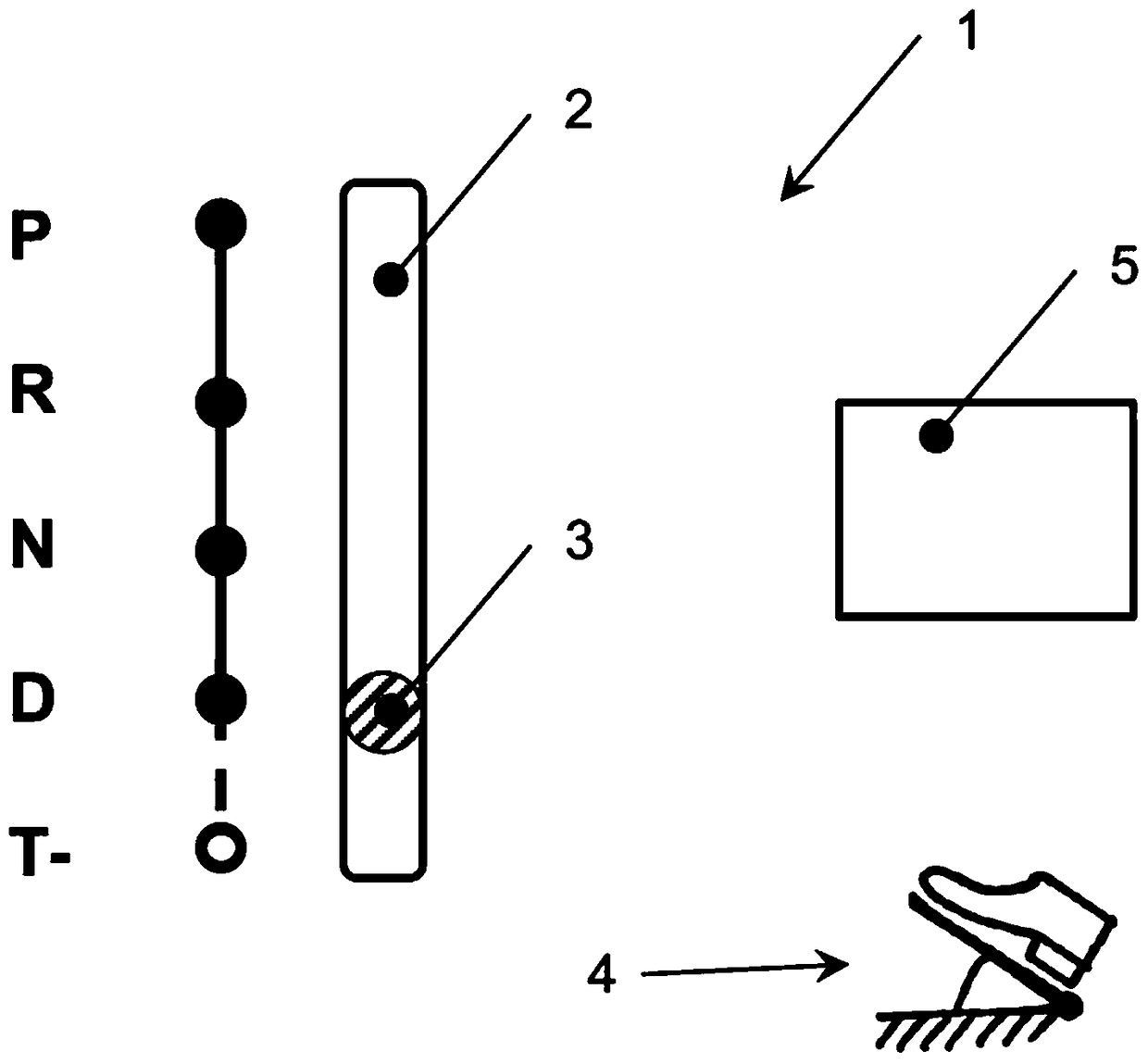

[0016] figure 1 shows a shifting device 1 with a selector gate 2 , wherein the selector gate has different positions for the selector lever 3 . From the stable parking position P, a stable reverse position R can be reached, from which then a stable parking position N can be reached, wherein a park gear is engaged in the transmission. From this parking position N, the selector lever 3 can be pivoted further into a stable forward position D. All these four positions P, R, N, D are designed as stable or detented positions, that is to say, after the shift lever 3 is deflected by the driver into one of these positions and he releases it subsequently After the selector lever, the selector lever 3 remains in this selected position. In addition, the shift gate also has an unstable position T- for downshifting, which can be reached from the forward position D. All mentioned positions P, R, N, D, T- lie on a line and the selector gate 2 is designed rectilinear. The unstable position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com