Heating furnace water beam binding method

A heating furnace and water beam technology, applied in the field of heat insulation and dressing, can solve the problems of unresolved water pipes, black marks, and reduce heat dissipation of water pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] For further describing the present invention, below in conjunction with embodiment the present invention is described in more detail:

[0017] 1. Take the hot continuous rolling heating furnace of a factory as an example. The heating temperature of the heating furnace is 1350°C, and the output is 120t / h. The billet pusher type heating furnace adopts vaporization cooling method and double drainage beam pipes. Using conventional methods, it is wrapped in a traditional two-layer structure. The thermal insulation layer is made of zirconium-containing fibers with a thickness of 20mm and 0.2w / m.k. The working layer is made of low-cement castables with a thickness of 50mm and 1.5w / m.k. Its vaporization cooling loss is detected to be 7.37%.

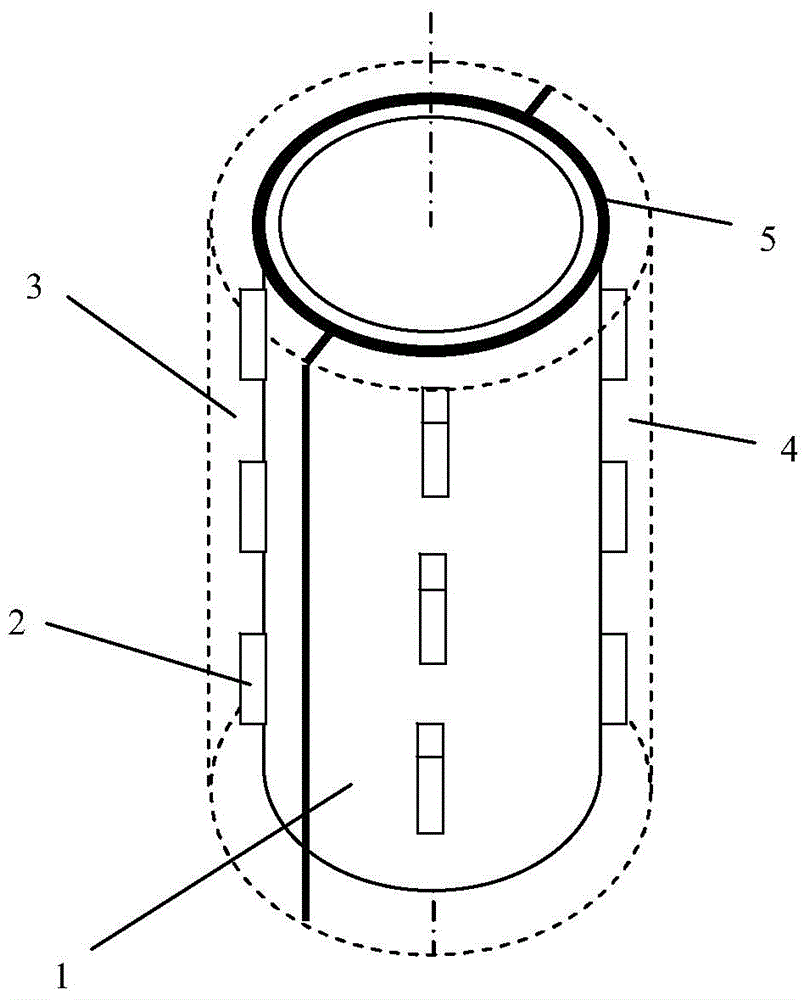

[0018] On the outer surface of the water pipe 1 at the bottom of the furnace, 4 square fixing blocks 2 are welded per meter of water beam pipe circumference, and a prefabricated block A3 that is semi-cylindrical and can cooperate with eac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com