An exposure machine with coding function

An exposure machine and functional technology, applied in the field of exposure machines with coding function, can solve the problems of increasing difficulty, increasing the risk of product quality tracking in production lines, and increasing the difficulty of tracking abnormal products, so as to shorten production time and increase production capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

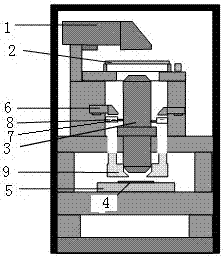

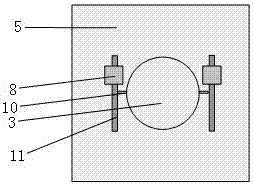

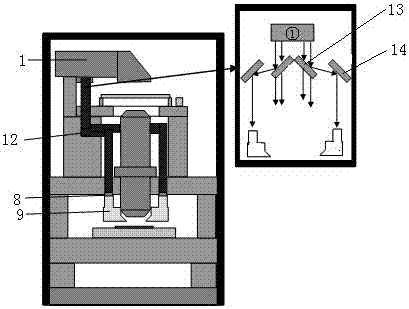

[0021] Such as figure 1 As shown, the exposure machine with coding function of the present invention includes an exposure system composed of a light source 1, a mask 2, an objective lens 3, a substrate 4, and a workpiece table 5 for pattern exposure of a substrate. It also includes a coding system composed of a light source 6, a coding system fixing module 7, a liquid crystal digital display mask 8, a coding position adjustment module 9, and coding and positioning software modules for coding during the exposure process. The coding system and the exposure system work at the same time. The coding system fixed module 7 is fixedly installed on both sides of the objective lens 3 lens barrel, such as figure 2 As shown, it includes a frame 10 and a guide rail 11. The liquid crystal digital display mask 8 is fixed on the guide rail 11. The guide ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com