Radial multi-coil parallel magnetic circuit multi-adhesion surface high-speed electromagnet

A technology of high-speed electromagnet and suction surface, applied in the field of electromagnet, can solve the problems affecting the safety, reliability and life of the electromagnet, the increase of current rising speed and decay speed, affecting the dynamic response characteristics of the electromagnet, etc., to achieve good magnetic permeability energy, reduce power consumption, and evenly distribute the magnetic induction intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in more detail below with examples in conjunction with the accompanying drawings.

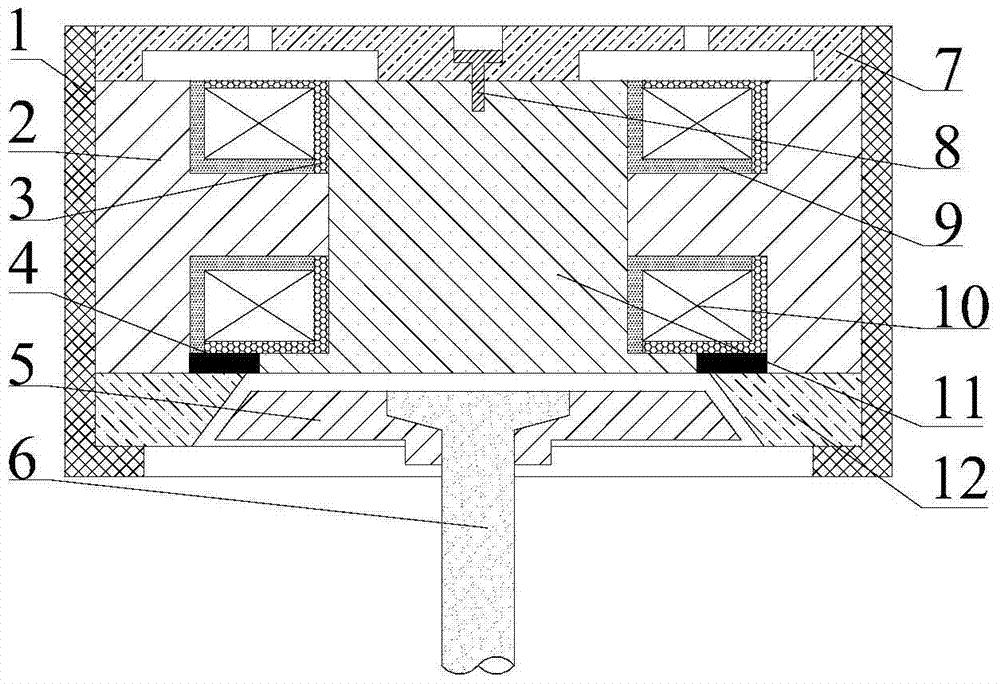

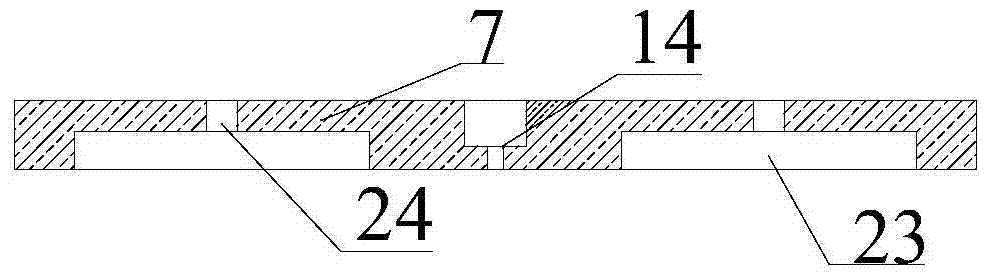

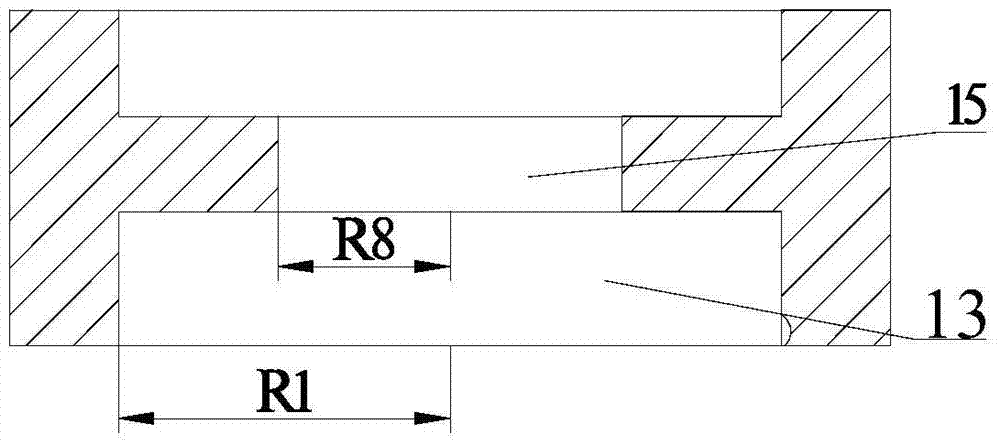

[0025] combine figure 1 , figure 2 , Figure 3(a), Figure 3(b), Figure 4 , Figure 5(a), Figure 5(b), Image 6 with Figure 7 , the composition of radial multi-coil parallel magnetic circuit multi-adhesion surface high-speed electromagnet of the present invention comprises housing 1, outer iron core 2, sealing resin 3, permanent magnet 4, armature 5, valve stem 6, fastening nut 7, Screw 8, bobbin 9, coil 10, inner core 11 and yoke 12. The housing 1 is a cylinder with a stepped through hole in the center, and the upper end is tapped with threads, and a fastening screw 7 is provided. The screw 7 has a countersunk hole 14 in the center, and an annular groove 23 at the bottom, and a cylindrical structure with a through hole 24 in the center of the groove; the outer iron core 2 has grooves 13 at both ends, and a groove in the center The cylinder o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com