A linear vibrating motor

A linear vibration and coil technology, applied in electrical components, electromechanical devices, etc., can solve the problems of thick thickness and short service life of linear vibration motors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

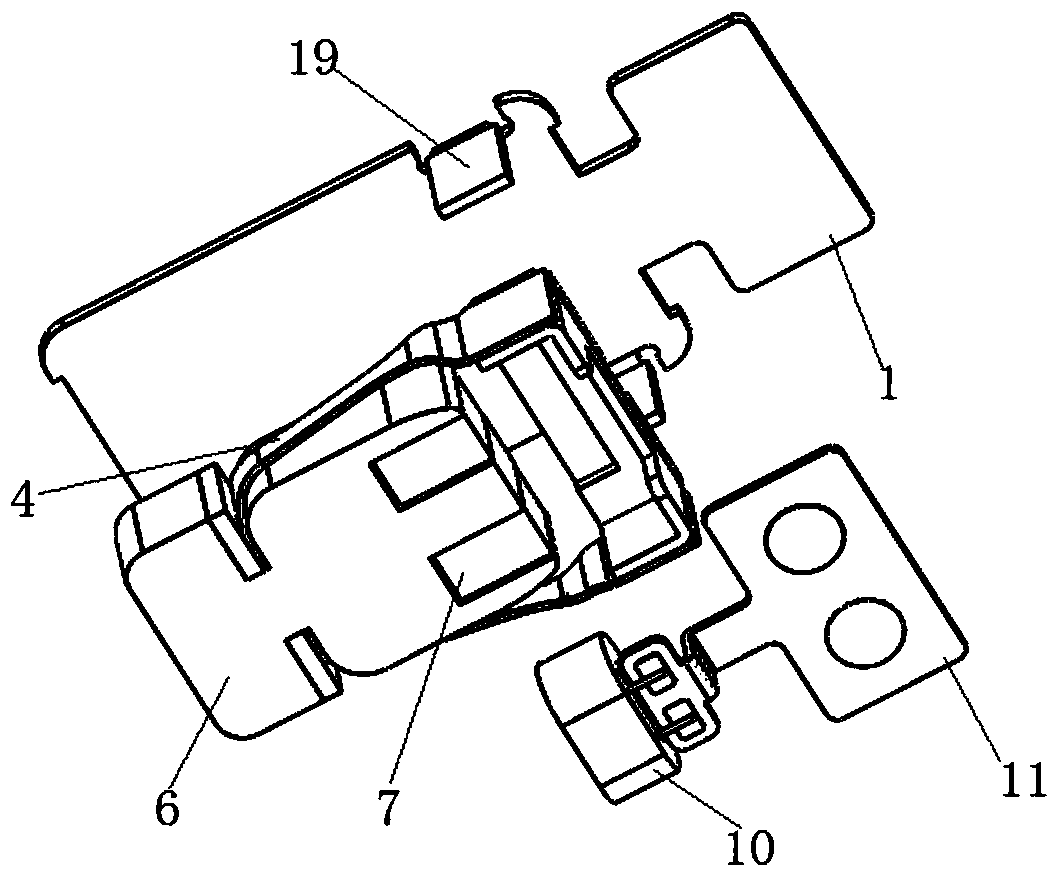

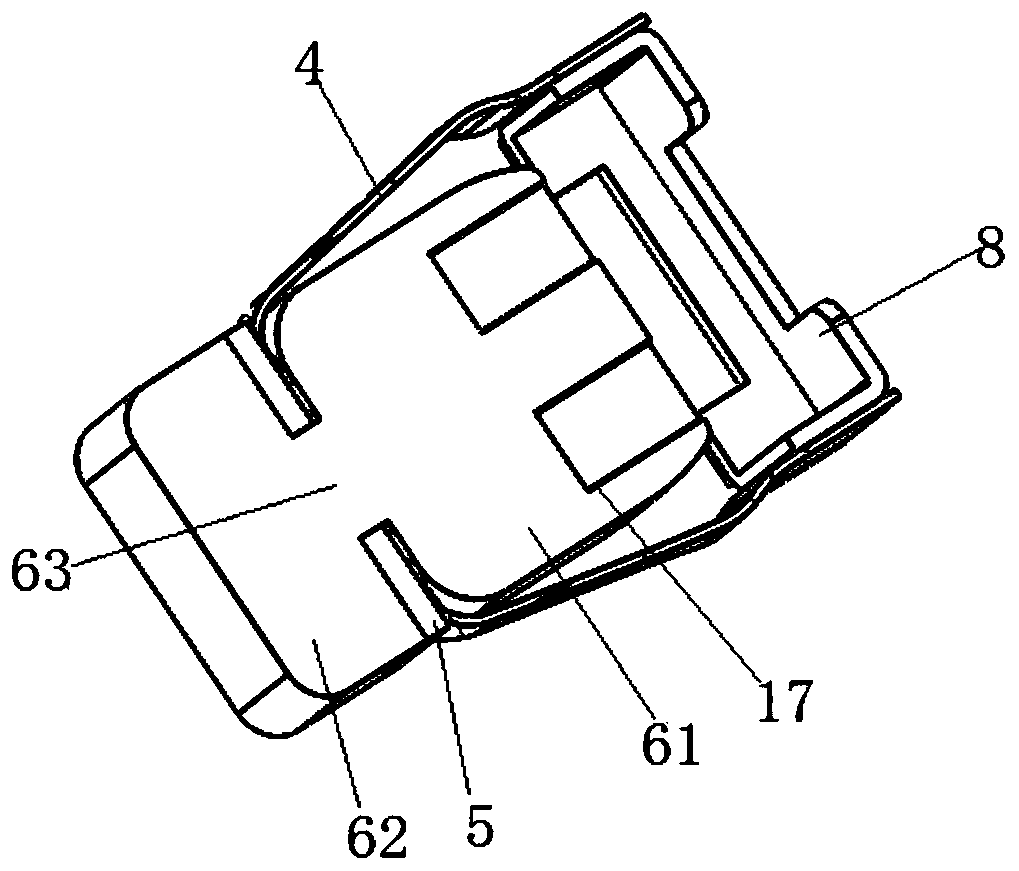

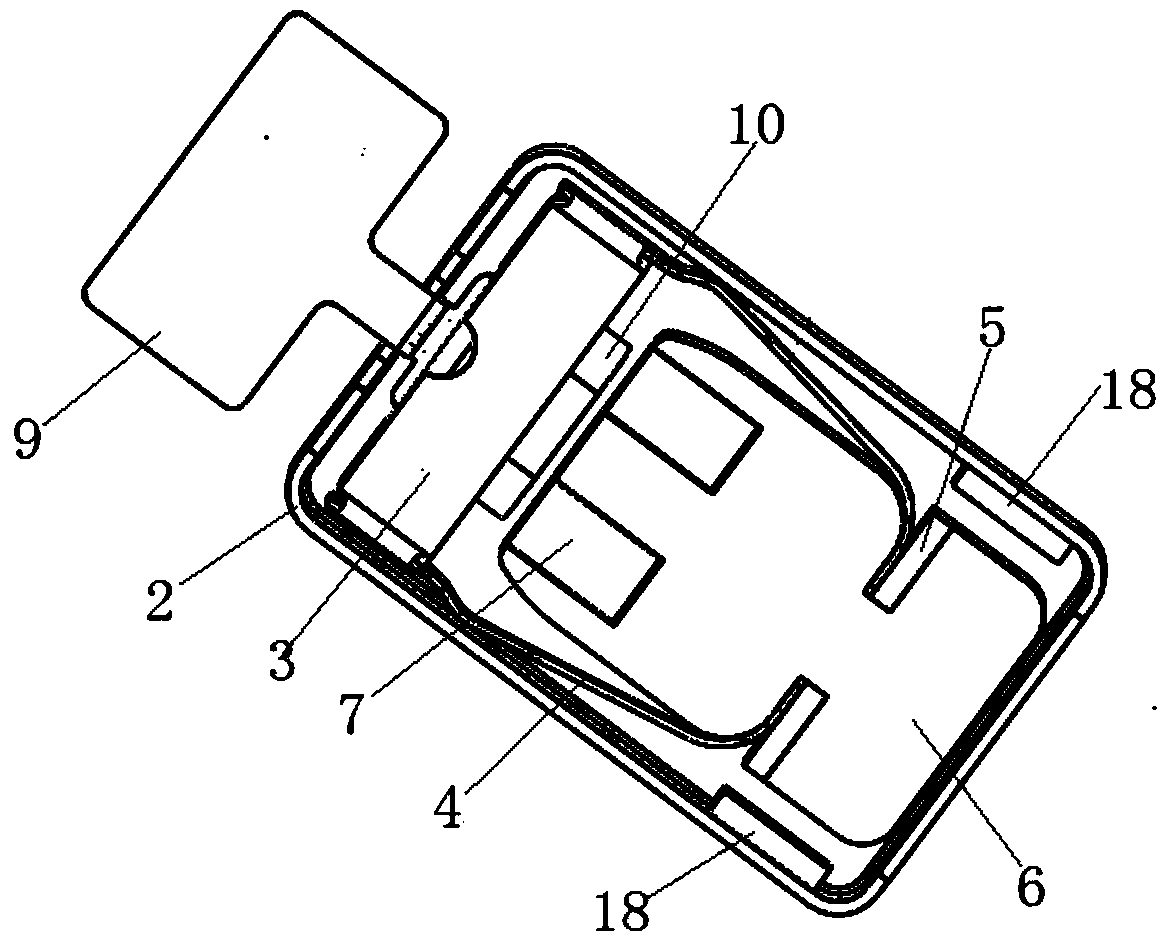

[0069] Such as figure 1 , figure 2 and image 3 As shown, the present embodiment 1 provides a linear vibration motor, including

[0070] Base 1, set along the horizontal direction;

[0071] The shell 2 is fixed on the base 1 and forms an installation space with the base 1;

[0072] A stator assembly, located in the installation space, has a coil 10 and a circuit board 11;

[0073] The vibration assembly is located in the installation space and is arranged opposite to the stator assembly along the first direction, including a mass block 6 and a magnet 7 installed on the mass block 6 close to the stator assembly;

[0074] an elastic component installed on the base 1 and located in the installation space, for suspending the vibrating component in the installation space;

[0075] The bracket 8 is arranged on the base 1, and is used to support the stator assembly, so that the coil 10 is horizontally opposite to the magnet 7;

[0076] When the coil 10 is energized, the mass 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com