Large transformer body compression device and compression technology

A compression device and transformer technology, applied in the field of transformers, can solve problems such as unreliable clamping of the iron core, unreliable compression of the body, unreasonable compression structure of the iron core window, etc., to achieve improved compression and compact layout Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

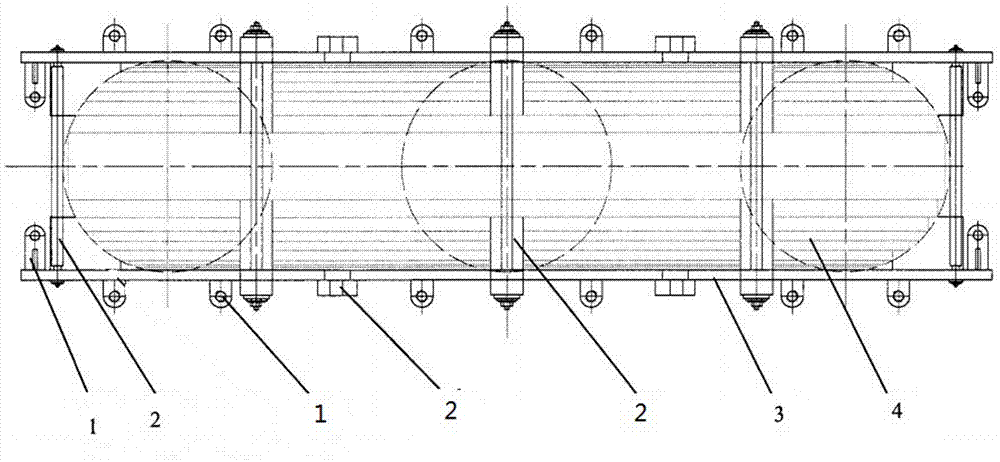

[0022] The large-scale transformer body compression system is composed of upper and lower clamps, steel straps, pull plates, pressure nails, nail holders, anti-lock nuts, etc. Among them, the upper and lower clamps, steel pull belts, and pull plates form an effective steel whole.

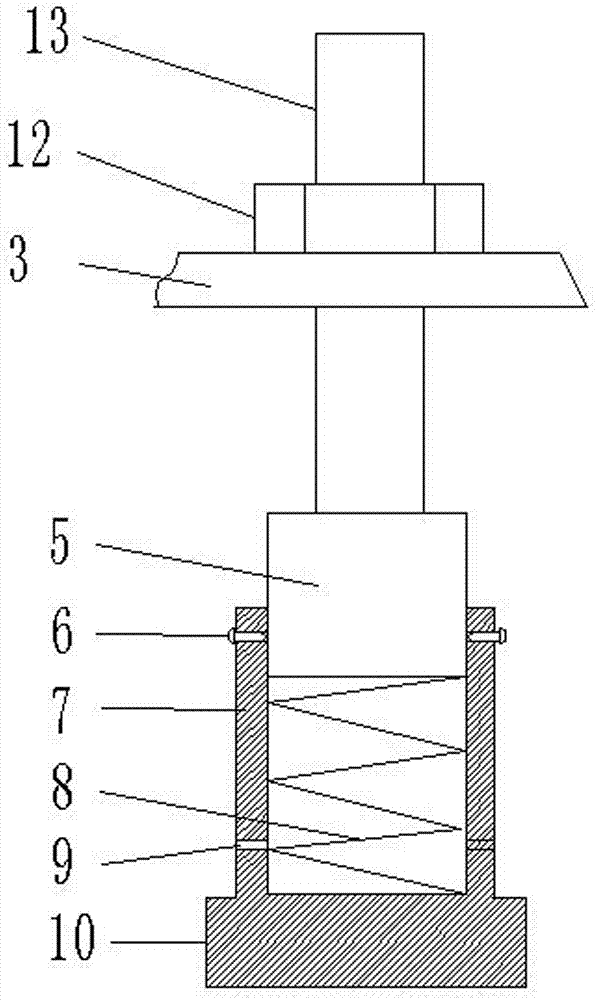

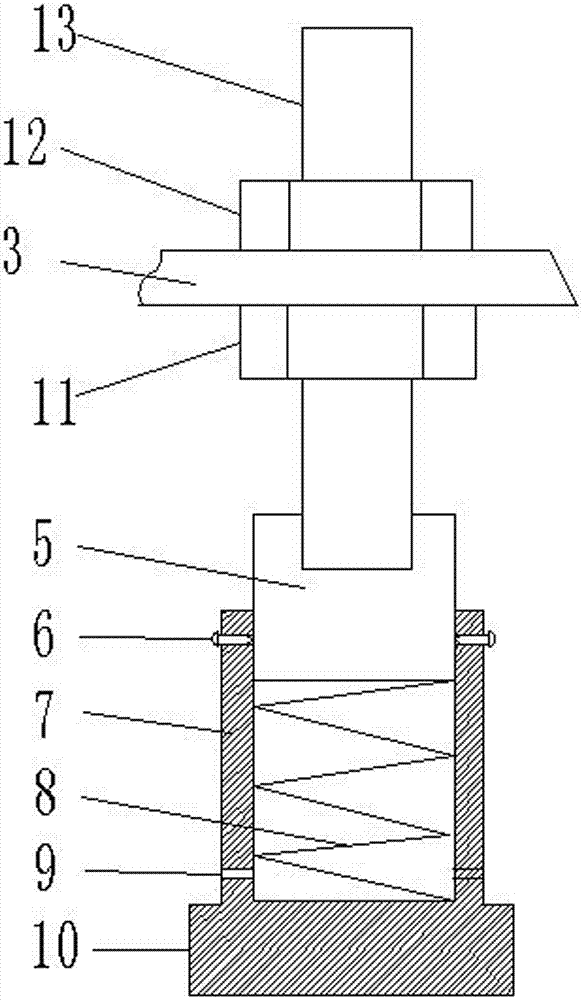

[0023] The compression structure adopts the structural form of pressing nails around and connecting the upper and lower pull-down plates. The pull-plate connection structure connects the upper and lower clamps, making the body a whole steel body. The silicon steel sheet does not shift up and down during the tightening process, and the nail structure is used to tighten the body.

[0024] The role of the tie plate connection structure is to connect the upper and lower clamps to form a stable steel body, which plays a role of support and clamping when the body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com