Tunnel-type hot-air tobacco-leaf-conditioning process and device used in process

A process method and tunnel-type technology, which is applied in the field of tobacco threshing and redrying processing, can solve the problems of difficult online real-time control of temperature and humidity, uneven temperature and humidity of tobacco leaves, and large breaking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

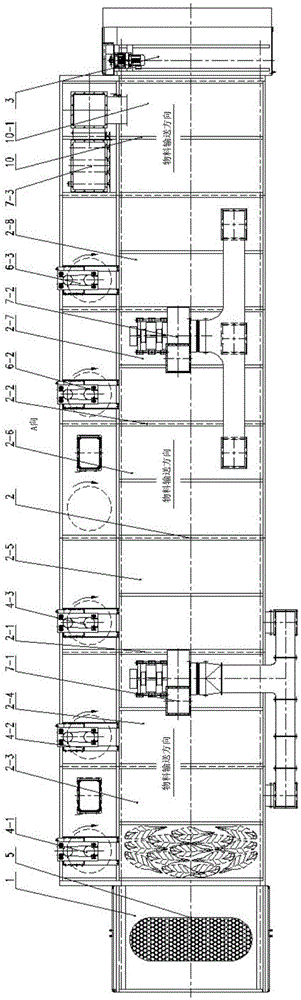

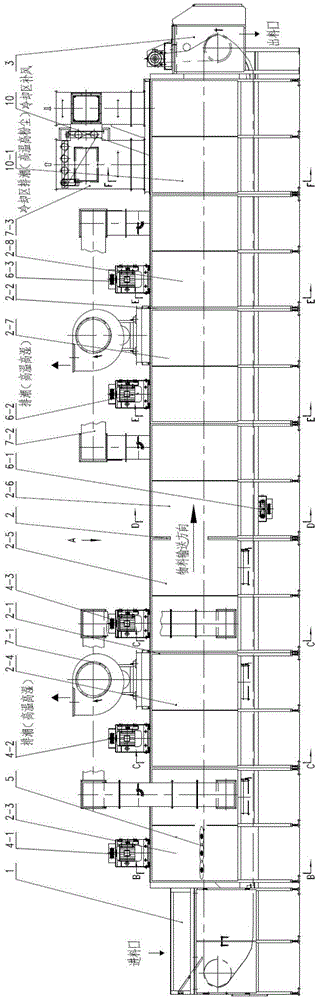

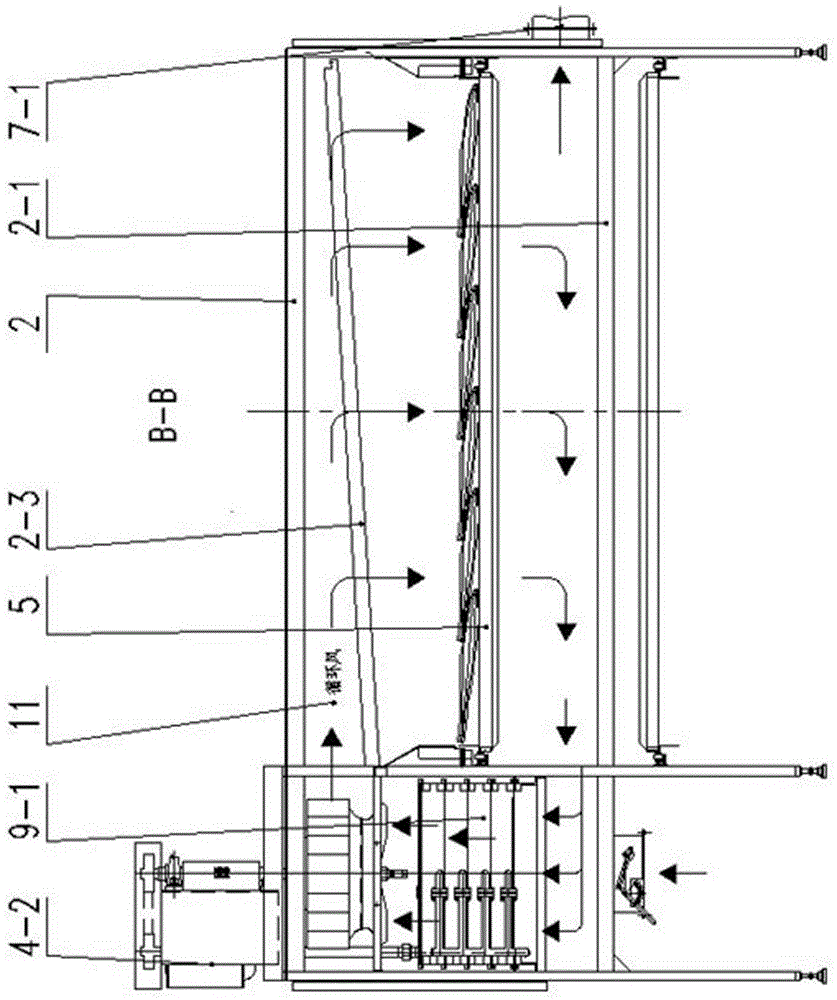

[0030] Such as figure 1 As shown, a tunnel-type hot air method and equipment for moistening leaves, the present invention is characterized in that the tobacco leaf moistening process adopts firstly increasing temperature and then humidifying, or adopts firstly increasing temperature, then humidifying, then increasing temperature, and then humidifying Tobacco leaves are moistened in multi-stages and sub-gradients to achieve moisture absorption after the tobacco leaves are warmed up, improve the wettability, and use hot air to increase the temperature; the moistening process uses a tunnel-type annular conveyor belt, and the tobacco leaves and the conveyor network The belt is relatively stationary during the heating and humidification process. Under the condition that the volume of the tobacco leaves remains unchanged, the leaf thickness is reduced to increase the area, and the hot air and high-temperature and high-humidity atomized steam-water mixture penetrates the material laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com