An intelligent conveying welding system and its conveying method

A welding system and conveying track technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of inconvenient single workpiece conveying, high equipment precision requirements, and expensive intelligent welding equipment, etc. Achieve the effect of improving processing performance and processing efficiency, scientific and reasonable design, and reducing design cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

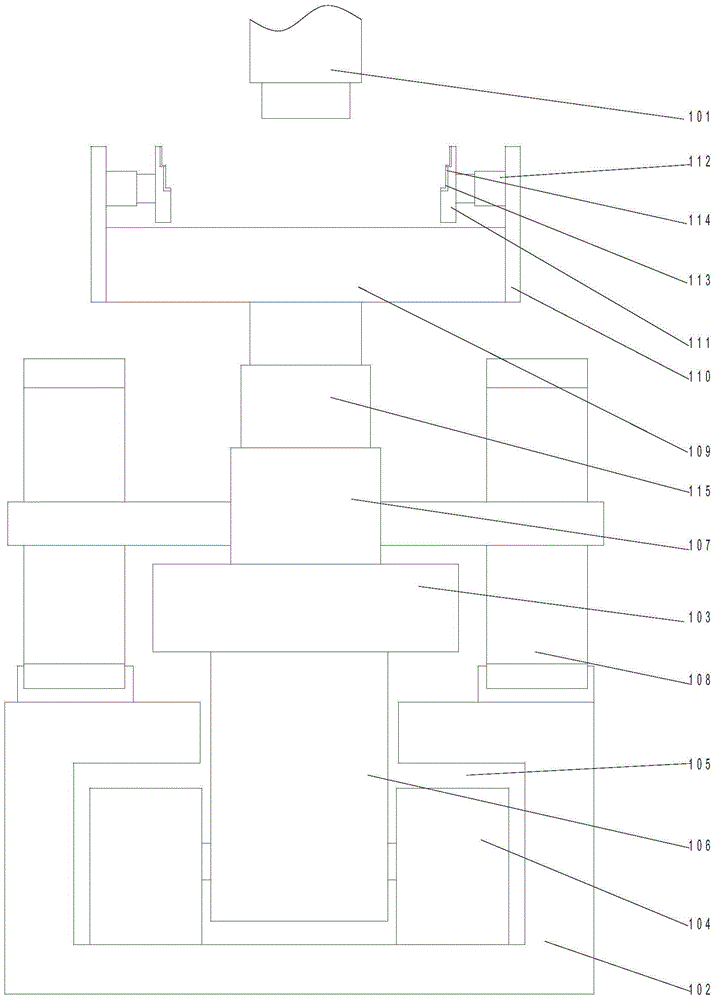

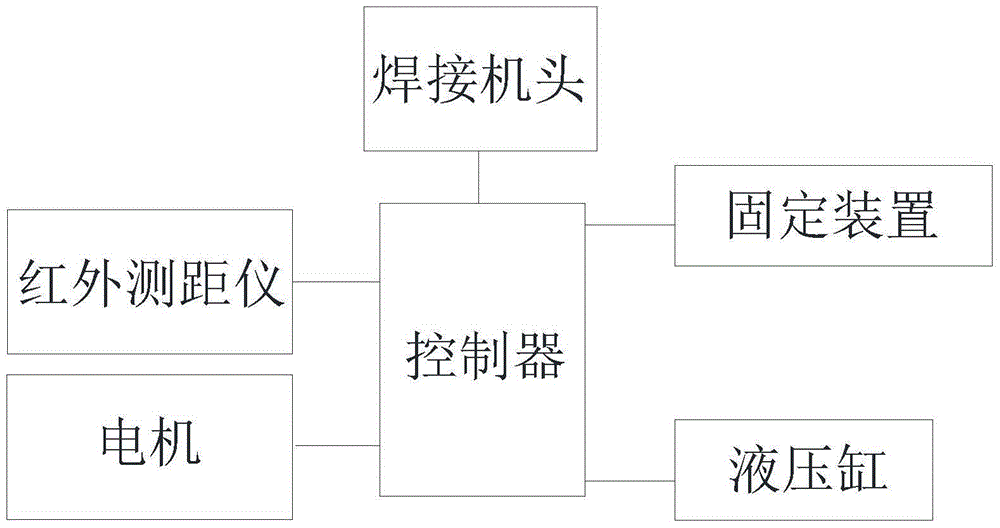

[0023] Such as figure 1 As shown, a welding system for intelligent transportation includes a welding head 101 and a conveying track 102 arranged below the welding head 101. A conveying device 103 is arranged on the conveying track 102. The conveying device 103 The lower end is provided with a roller 104 matched with the conveying track 102, and the middle part of the conveying track 102 is provided with a T-shaped channel 105, and the rollers 104 are arranged symmetrically in the channel 105. 2, a vertical rod 106 is arranged at the lower end of the conveying device 103, and the two rollers 104 are respectively rotatably connected to both sides of the vertical rod 106, and a motor 107 is arranged in the conveying device 103, The output shaft of the motor 107 is provided with two gears 108, and the upper end surface of the conveying track 102 is provided with teeth meshed with the gears 108, and on the upper end surface of the conveying device 103 A support platform 109 is pro...

Embodiment 2

[0029] On the basis of Embodiment 1, this embodiment also discloses an intelligent delivery method, including the following steps:

[0030] S1: Preset the workpiece conveying frequency in the controller, determine the distance between adjacent conveying devices according to the workpiece conveying frequency, detect the distance between adjacent conveying devices by the infrared range finder, and send it to the controller;

[0031] S2: When the conveying device is located under the welding head, the controller sends drive information to the motor to stop the motor and fix the transmission gear to the teeth on the conveying track for fixing;

[0032] S3: The controller sends a driving signal to the welding head, and the welding head starts to run for welding;

[0033] S4: After the welding is completed, the controller sends a driving signal to the motor, and the motor runs to make the transmission gear run along the conveying track;

[0034] S5: When a single conveying device s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com