Automatic material placing device

A material placement and automatic technology, applied in the direction of claw arms, manipulators, program control manipulators, etc., can solve the problems of increasing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below by means of specific embodiments:

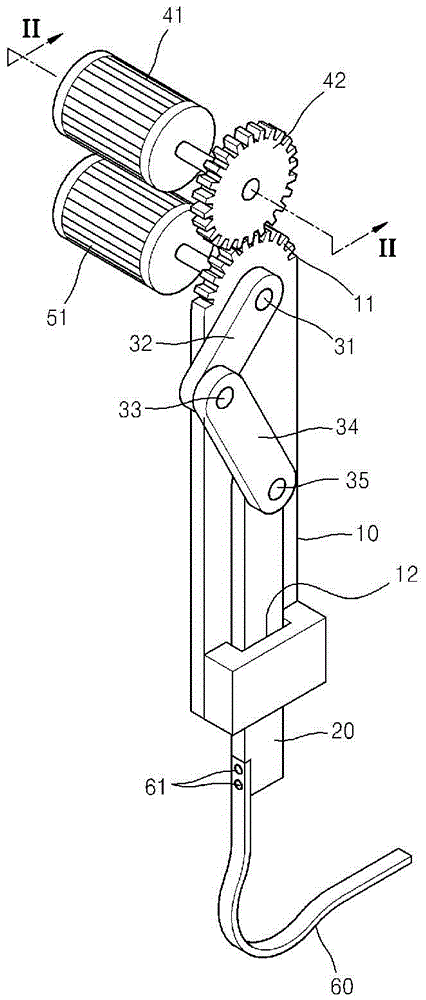

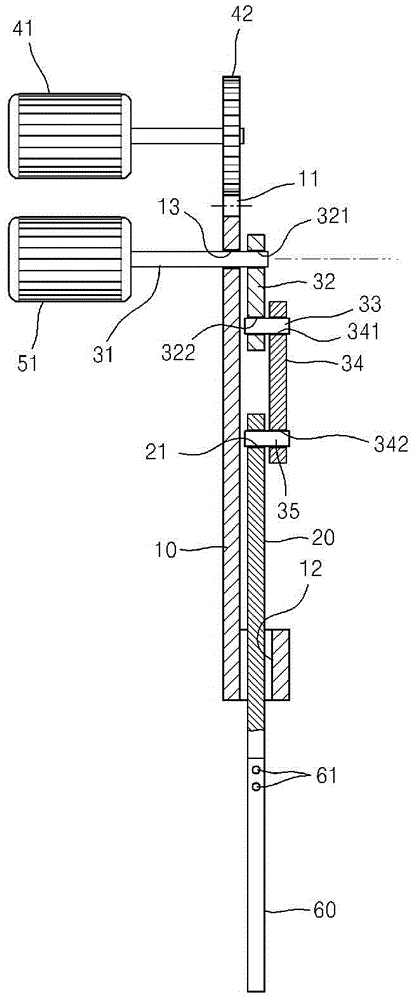

[0020] The reference numerals in the drawings of the description include: motor one 41, output shaft 31 of motor two, motor two 51, rotating gear 42, half circle of teeth 11, first connecting rod 32, second connecting rod 34, base plate 10, Limiting slot 12, slider 20, storage hook 60, first pin hole 322, second pin hole 341, pin shaft 33, perforation 13, shaft hole 321, pivot shaft 35, third pin hole 21, fourth pin hole 342. Fixing nail 61.

[0021] The embodiment is basically as attached figure 1 As shown: the automatic material placement device of this embodiment includes a motor one 41, a motor two 51 and a telescopic arm, and the telescopic arm includes a bottom plate 10 and a material hook that is slidably connected to the bottom plate 10.

[0022] like figure 2 As shown, there is a certain gap between the first motor 41 and the second motor 51 to avoid mutual i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com