Paperboard V-groove machine

A slot machine and cardboard technology, applied in the field of processing equipment, can solve the problems of high labor intensity, heavy labor, easy to skew, etc., and achieve the effect of overcoming easy skew and automatic continuous feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

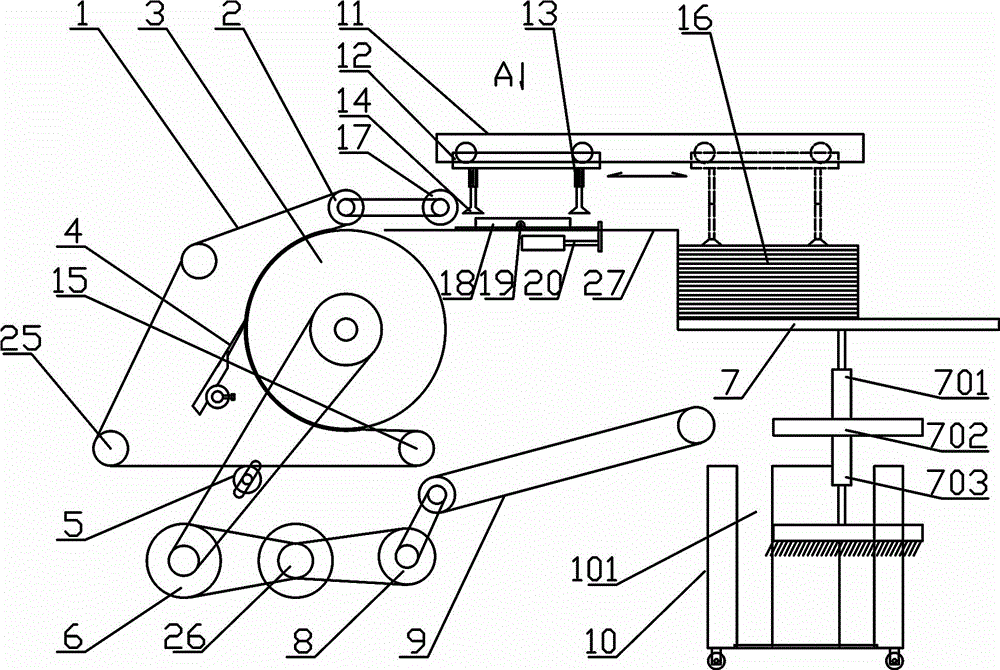

[0018] Such as figure 1 , 2 Among them, a cardboard V-groove machine includes a main roller 3 driven to rotate by a driving device. In the driving device, a motor 26 is connected to a first reducer 6, and the first reducer 6 is connected to the main roller 3 through a belt. What the first speed reducer 6 in this example adopted is the belt pulley of different diameter of coaxial.

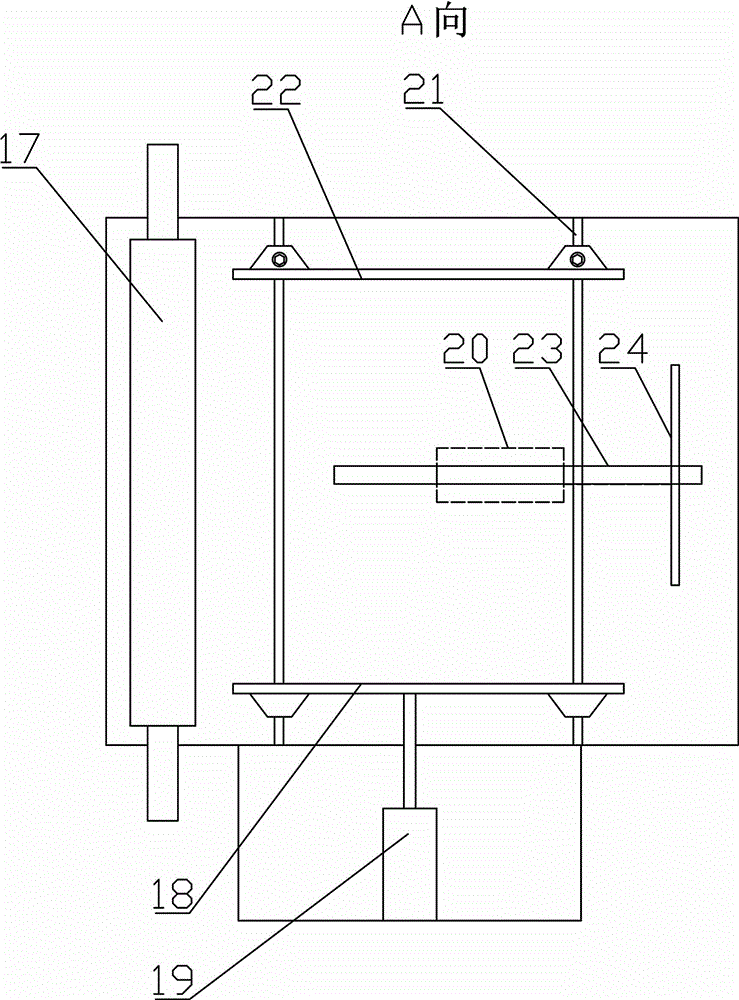

[0019] The upper part of the main roller 3 is provided with a top roller 2, the lower part of the main roller 3 is provided with a bottom roller 15, and a plurality of guide rollers 25 are also provided between the top roller 2 and the bottom roller 15, and a plurality of adhesive tapes 1 bypass the top roller 2, the main roller Part of the outer surface of the roller 3, the bottom roller 15 and the guide roller 25 form a loop, the part where the main roller 3 is wrapped by the adhesive tape 1 is provided with a slotting knife 4, and a vacuum suction feeding device is provided above the feeding pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com