Baffle turnover mechanism

A technology of overturning mechanism and frame, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of high labor intensity and low work efficiency of operators, and achieve the effect of reducing labor intensity, improving work efficiency and reducing participation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

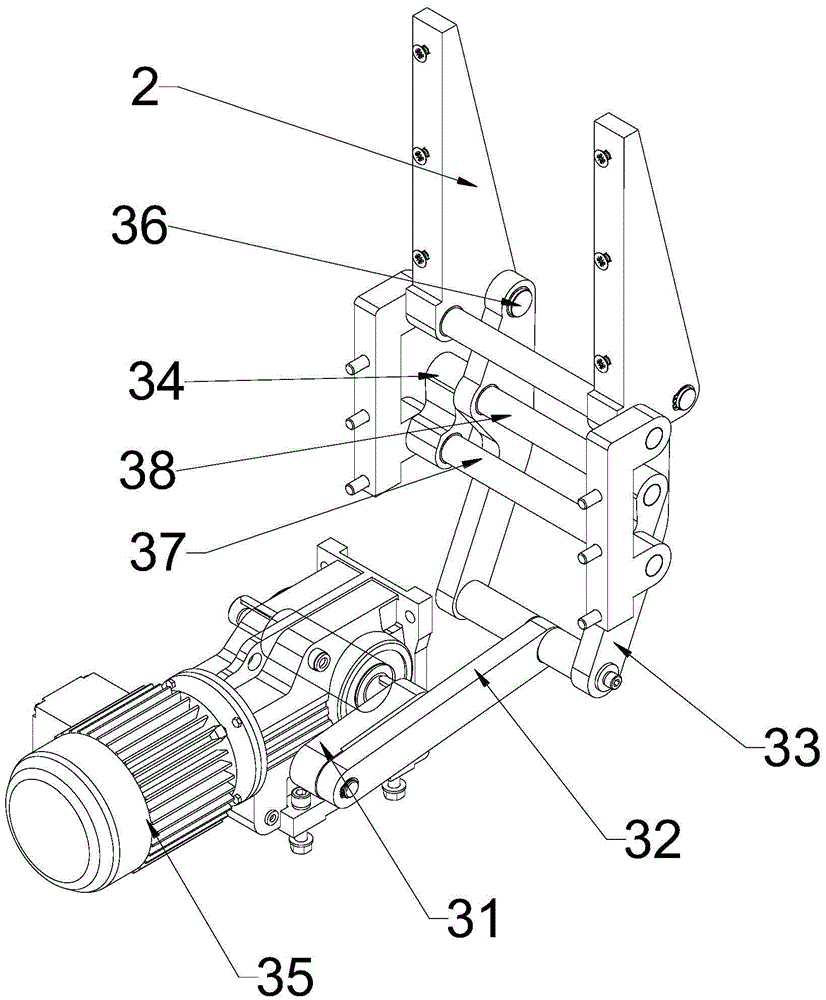

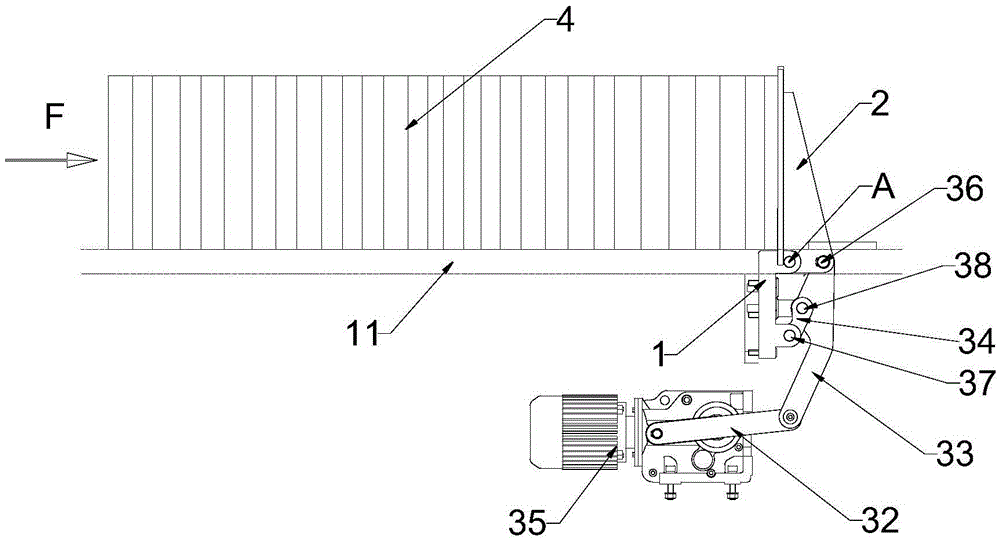

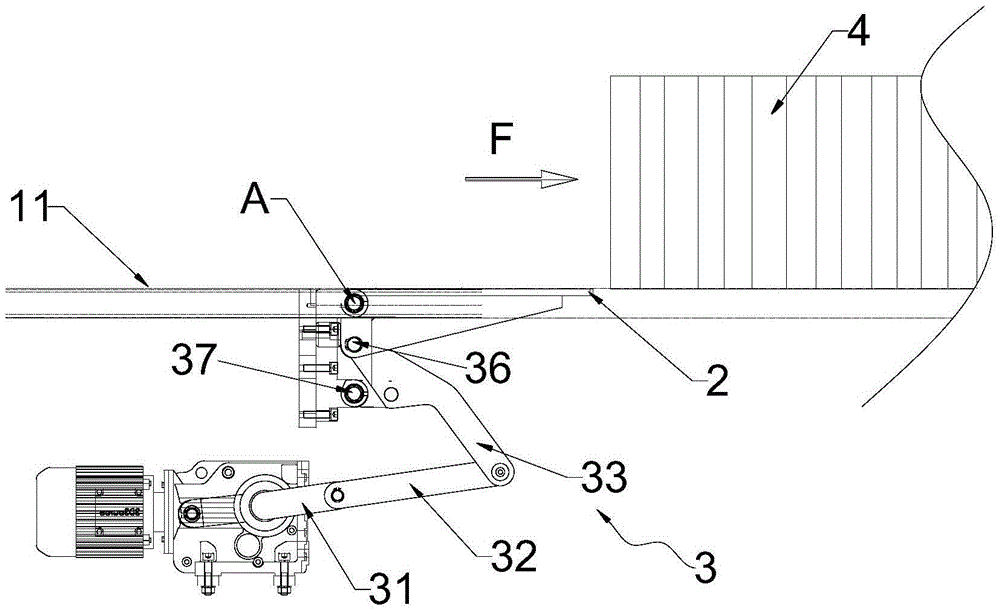

[0019] like Figure 1-3 As shown, the baffle turning mechanism of the present invention includes a frame 1, a stopper 2 pivotally connected to the frame 1, and a driving mechanism 3; the frame 1 is provided with a workpiece placement surface for placing the processing object 11; the driving mechanism 3 is used to drive the stopper 2 to rotate between the first position and the second position protruding from the workpiece placement surface 11; when the stopper 2 is in the second position, the stopper 2 The upper surface of the upper surface is flush with the workpiece placement surface 11; the driving mechanism 3 includes a crank 31, a connecting rod 32, a link 33, a swing member 34, and a power part 35; the link 33 includes a first end, a second end part, the connecting part arranged between the first end and the second end; one end of the crank 31 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com