Synchronous clamping assembly test stand for two-sided ultraviolet ageing test

A technology of aging test and component test, which is applied in the field of component test racks, can solve the problems of reducing the service life of components and aging of packaging materials, and achieve the effect of convenient front and rear position adjustment and improved efficiency of ultraviolet aging test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiments of the present invention will be described in detail below in conjunction with the drawings:

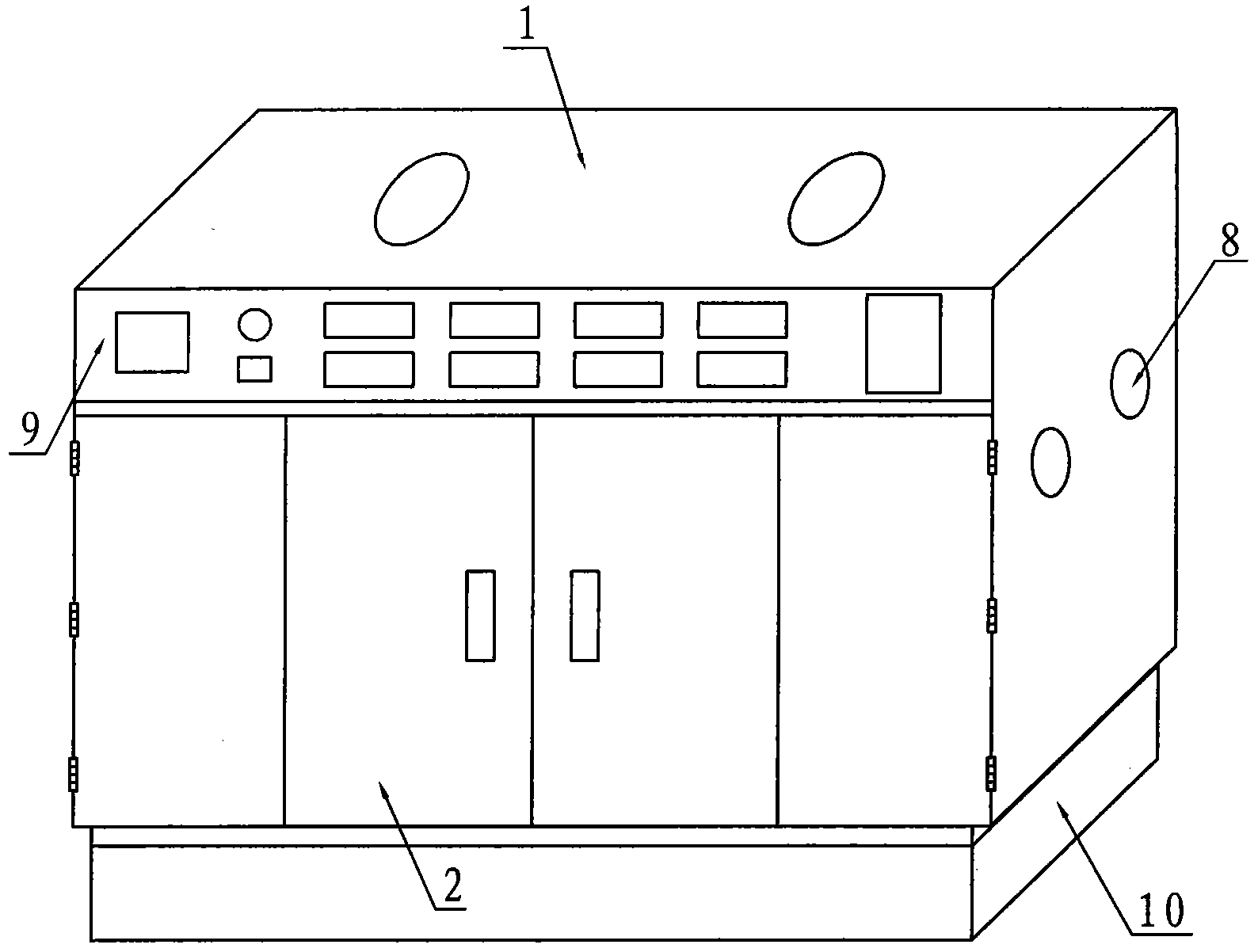

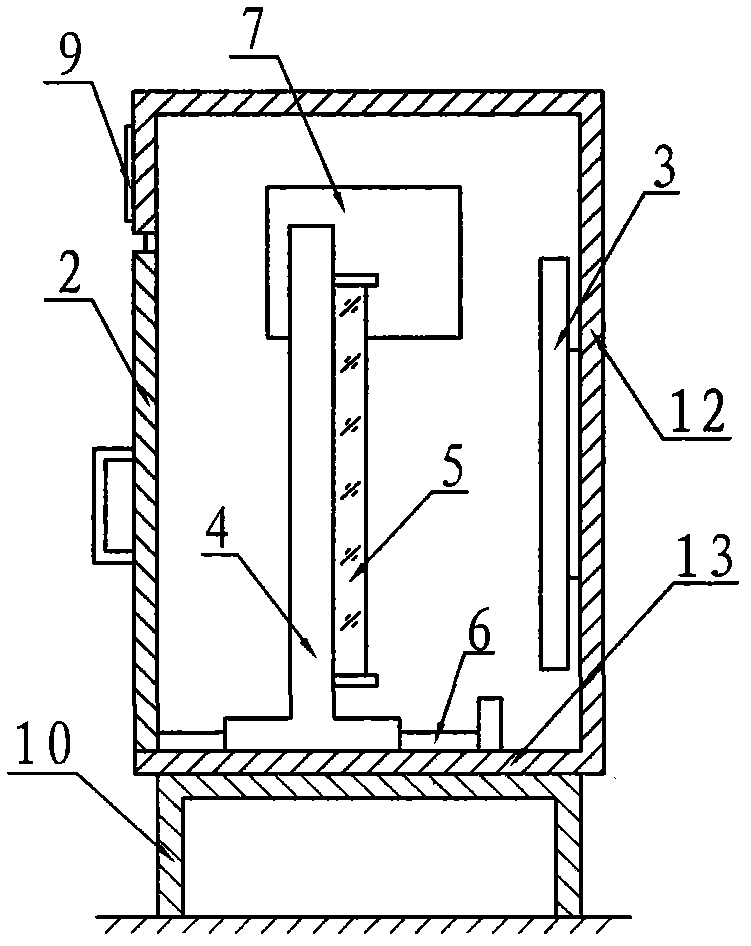

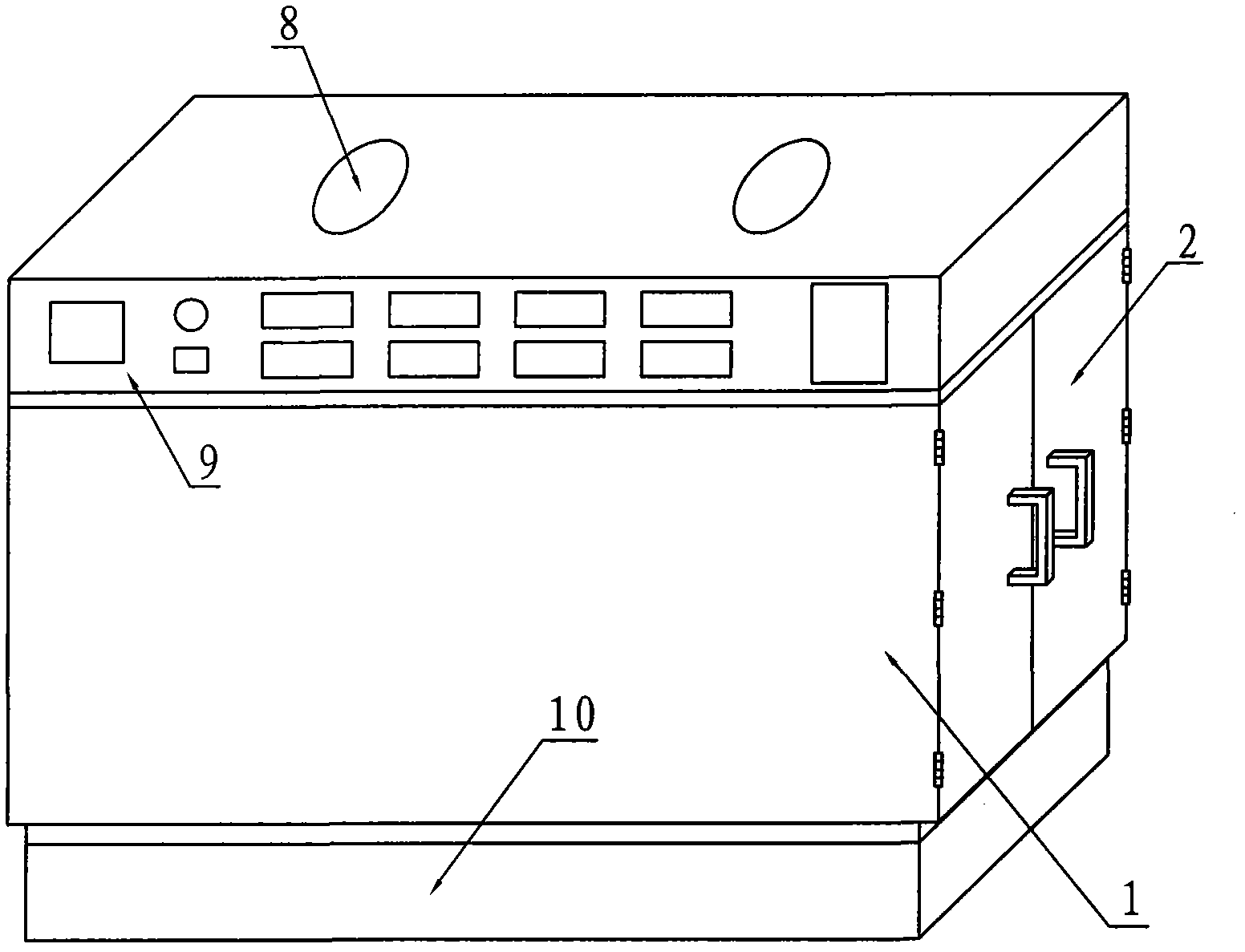

[0017] Figure 3 ~ Figure 4 It is a schematic diagram of the structure of the UV aging test box for double-sided radiation testing. It includes a box body 1, a box door 2, a fluorescent ultraviolet lamp 3, a component test frame 4, a battery assembly 5 and a guide rail 6, and the box door 2 is set on the box body 1. On the left side or right side, the fluorescent ultraviolet lamp 3 is installed on the front side 11 and the rear side 12 in the box 1, and the guide rail 6 is installed on the bottom surface 13 of the box 1, and is connected to the front side 11 and the rear side. 12 Parallel, the battery components 5 to be tested are installed on the front and back sides of the component test frame 4, the bottom of the component test frame 4 is provided with a rolling structure corresponding to the guide rail 6, and the innermost end of the guide rail 6 is pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com