Fabric rolling drum with reel provided with evenly distributed annular grooves

A technology of annular grooves and cloth rolls, which is applied in the field of textile machinery, can solve the problems of slipping and time-consuming between the rolls and fabrics, and achieve the effects of preventing slipping, increasing the contact area, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

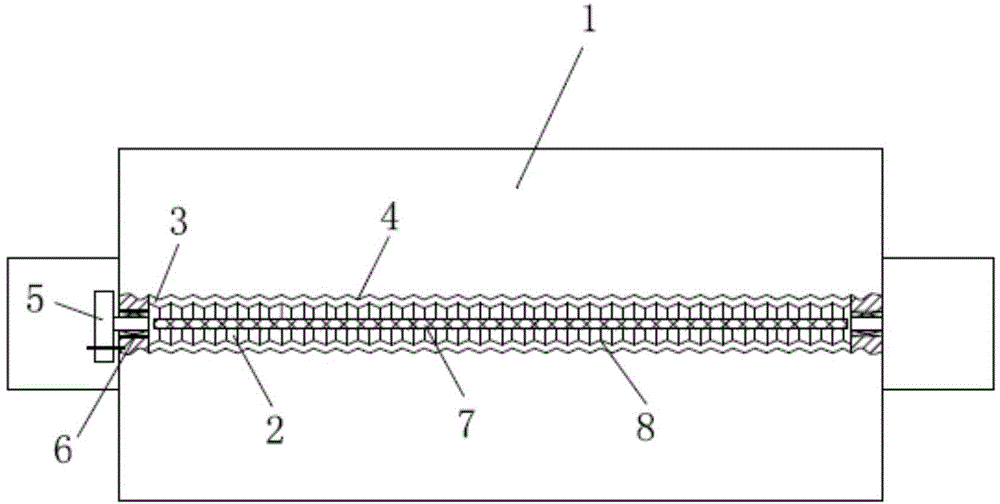

[0015] Attached below figure 1 The technical solutions of the present invention are further described through specific implementation methods.

[0016] A cloth roll with annular grooves evenly distributed on the reel, including a cylinder body 1 and a reel 2 for fastening the cloth head, the outer circumference of the cylinder body 1 is provided with a long groove 3, and the long groove 3 The reel 2 is arranged inside, and a gap is provided between the side of the long groove 3 and the reel 2, and the side walls on both sides of the long groove 3 are provided with sawtooth 4, and the sawtooth and the interval The annular groove arranged on the reel is matched, the outer peripheral surface of the reel 2 is axially provided with an adhesive layer 7 for pre-fixing the cloth head, and the end shafts at both ends of the reel 2 are provided with bearings 6, the Bearings 6 are erected on the side walls at both ends of the cylinder body 1, and a rotating handle 5 is provided on the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com