Hoisting tool and hoisting method for prefabricated grillage beam

A hoisting tool and hoisting method technology, applied in the directions of transportation and packaging, load hoisting components, etc., can solve the problems of low work efficiency, reduced hoisting efficiency, unsafe, etc., and achieve convenient and rapid construction, improve construction efficiency, and safety. Sex-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

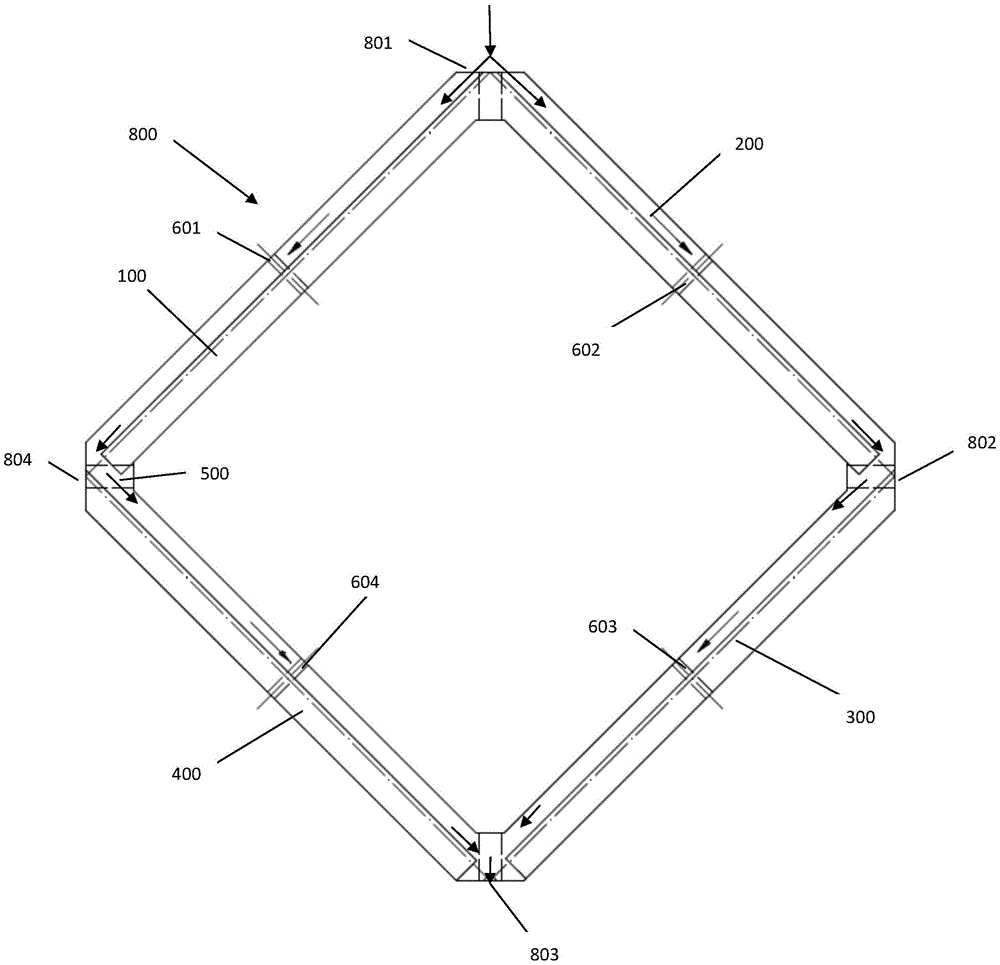

[0048] The structures involved in the present invention or the technical terms used are further described below. In the following detailed description, reference texts accompanying the legends are a part hereof, and are presented by way of illustration of certain embodiments in which the invention may be practiced. We do not exclude that the present invention can implement other specific solutions and change the structure of the present invention without departing from the scope of use of the present invention.

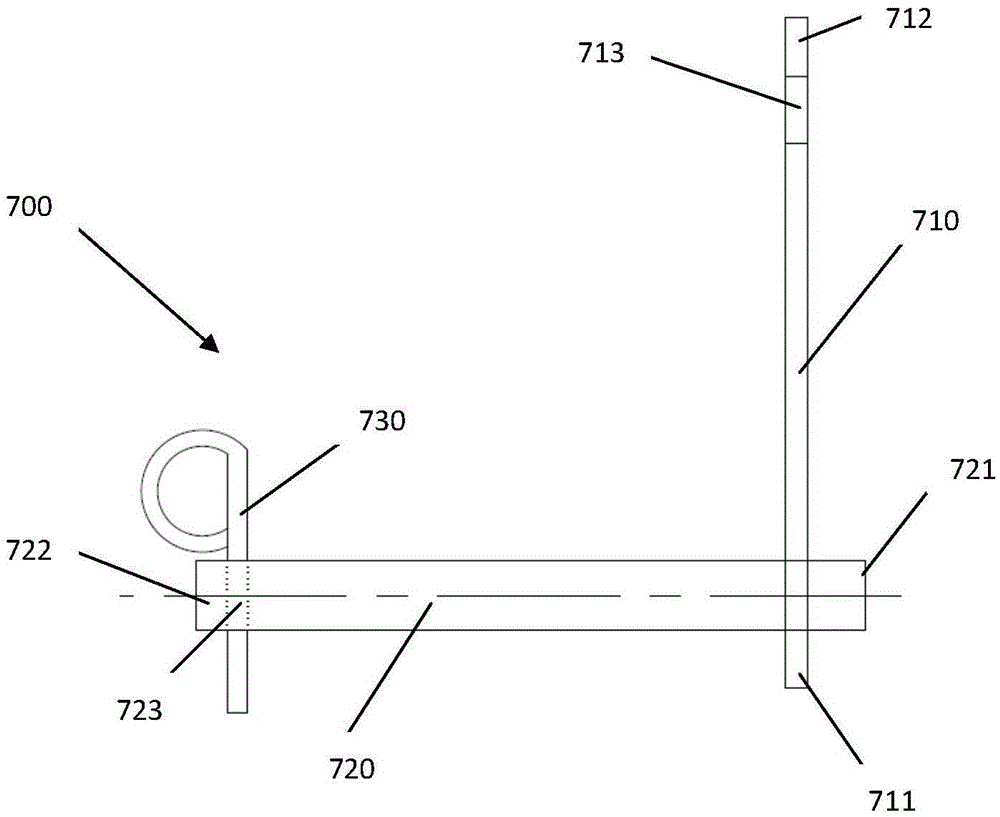

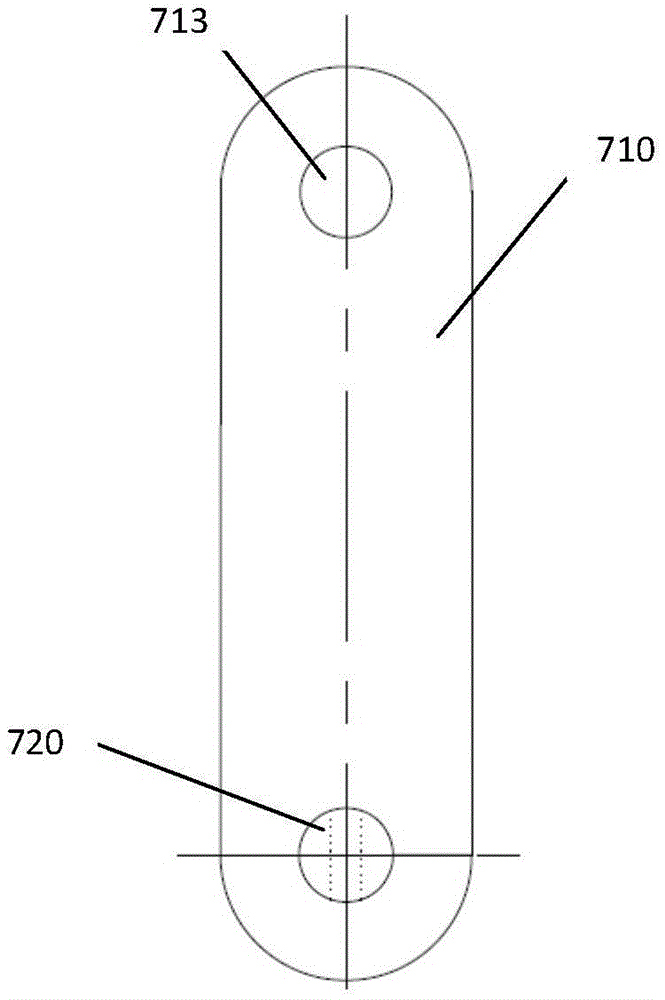

[0049] Such as figure 1As shown, the lifting tool 700 is formed by connecting a hanging shaft 720 and a hanging plate 710. Specifically, one end 721 of the hanging shaft 720 passes through the center of one end 711 of the hanging plate 710 and is fixedly connected together. In a specific embodiment, the suspension shaft 720 is welded and fixed on the suspension plate 710 . There is a connecting hole 713 on the hanging plate 710, and the connecting hole 713 is locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com