Transformer oil base oil with low freezing point and high naphthenic carbon content and preparation method of transformer oil base oil

A technology of transformer oil and base oil, which is applied in the direction of base material, petroleum industry, and hydrocarbon oil treatment, and can solve the problems of low yield and insufficient yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

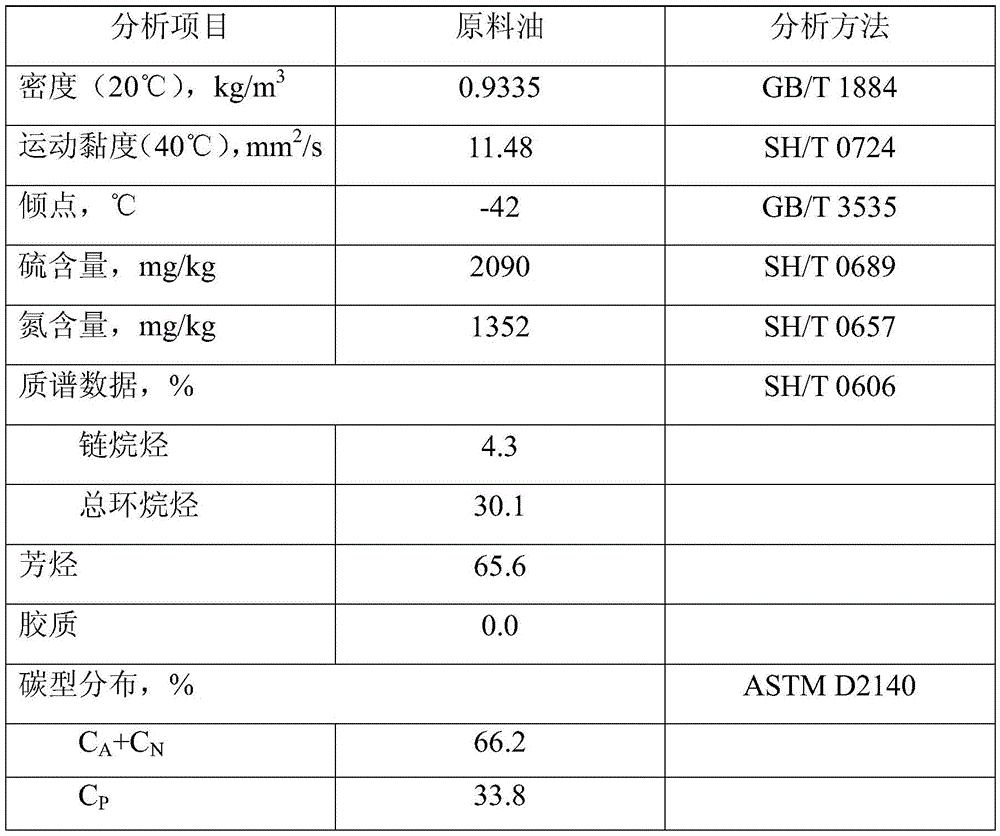

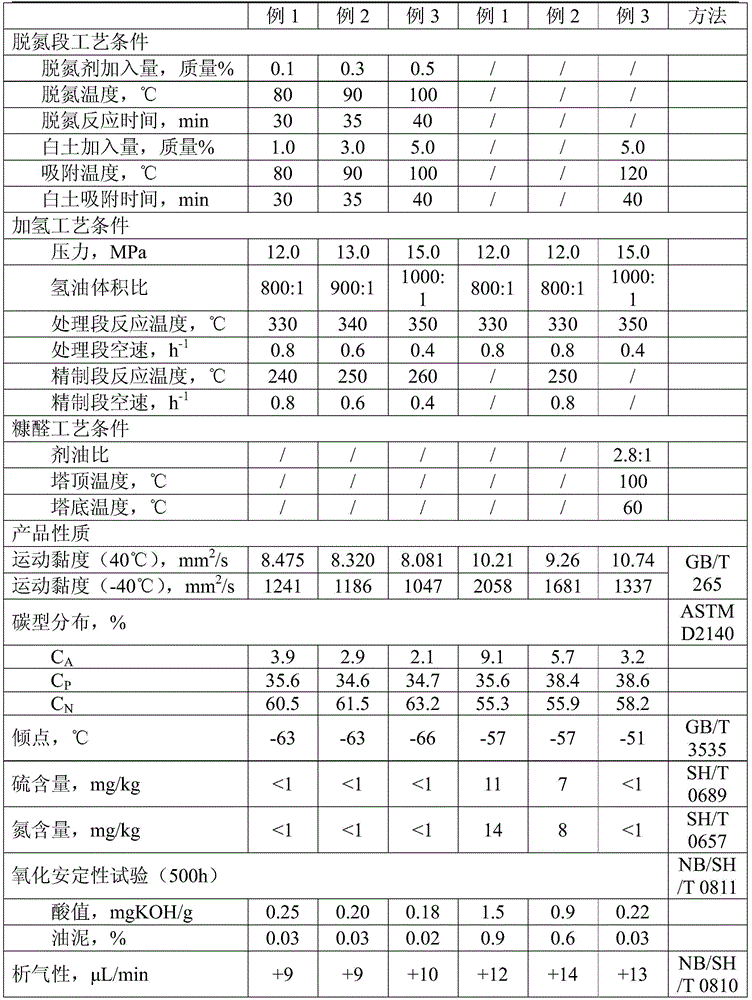

[0025] (1) Take Qinhuangdao 32-6 normal pressure distillation range 290℃-340℃ furfural refined extraction oil as raw material (see Table 1 for detailed properties), add denitrification agent WSQ-2 and clay for refining to obtain denitrification refined oil ;

[0026] (2) Using the denitrification refined oil obtained in step 1) as the raw material, the hydrogenation test is carried out in the hydrogenation pilot plant (produced by Shanghai Minrell Experimental Equipment Co., Ltd., two reactors are connected in series, and the maximum loading of catalyst in a single reactor is 200mL , The new hydrogen passes once), the first reactor is filled with the hydrotreating catalyst LH-23 catalyst, and the second reactor is filled with the hydrotreating catalyst FV-10 catalyst. The detailed operating parameters are shown in Table 2, and then proceed. Distillation cutting to obtain the transformer oil base oil provided by the present invention.

[0027] According to the data in Table 2, the ...

Embodiment 2

[0036] The processing flow of Example 2 is exactly the same as that of Example 1. The feedstock oil, hydrogenation test device, hydrotreating catalyst, hydrogenation supplemental refining catalyst, denitrification agent, and adsorbent are also the same. The specific operating parameters are different from those of Example 1 (details See Table 2).

[0037] According to the data in Table 2, the base oil pour point of the transformer oil is -63℃, and the kinematic viscosity (-40℃) is 1186mm. 2 / s, gassing property +9μL / min. It can be seen from the carbon type distribution data that compared with the raw material, its C P The value remains basically unchanged, and C N The value is as high as 61.5%, indicating that the cycloalkane basically does not open the ring during this process, and has excellent oxidation stability and electrical properties. It shows that the transformer oil base oil with low condensation and high naphthenic carbon content has excellent properties.

Embodiment 3

[0039] The processing flow of Example 3 is exactly the same as that of Example 1. The feedstock oil, hydrogenation test device, hydrotreating catalyst, hydrogenation supplemental refining catalyst, denitrification agent, and adsorbent are also the same. The specific operating parameters are different from those of Example 1 (details See Table 2).

[0040] According to the data in Table 2, the base oil pour point of the transformer oil is -66℃, and the kinematic viscosity (-40℃) is 1047mm. 2 / s, gassing property +10μL / min, it can be seen from the carbon type distribution data that compared with the raw material, its C P The value remains basically unchanged, and C N The value is as high as 63.2%, indicating that the cycloalkane basically does not open the ring during this process, and has excellent oxidation stability and electrical properties. It shows that the transformer oil base oil with low condensation and high naphthenic carbon content has excellent properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pour point | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap