Clutch apparatus

A technology of clutch device and clutch sleeve, which is applied in the field of washing machines, can solve the problems of troublesome manufacturing and installation, large support connectors, large direct drive motors, etc., and achieve the effect of simplifying manufacturing and installation, meeting installation requirements, and convenient and quick installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

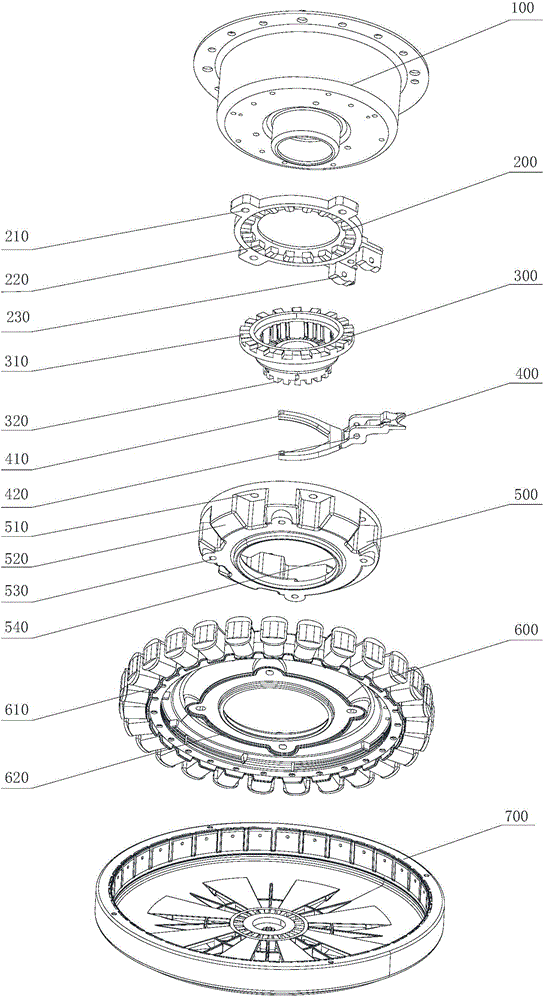

Image

Examples

Embodiment 1

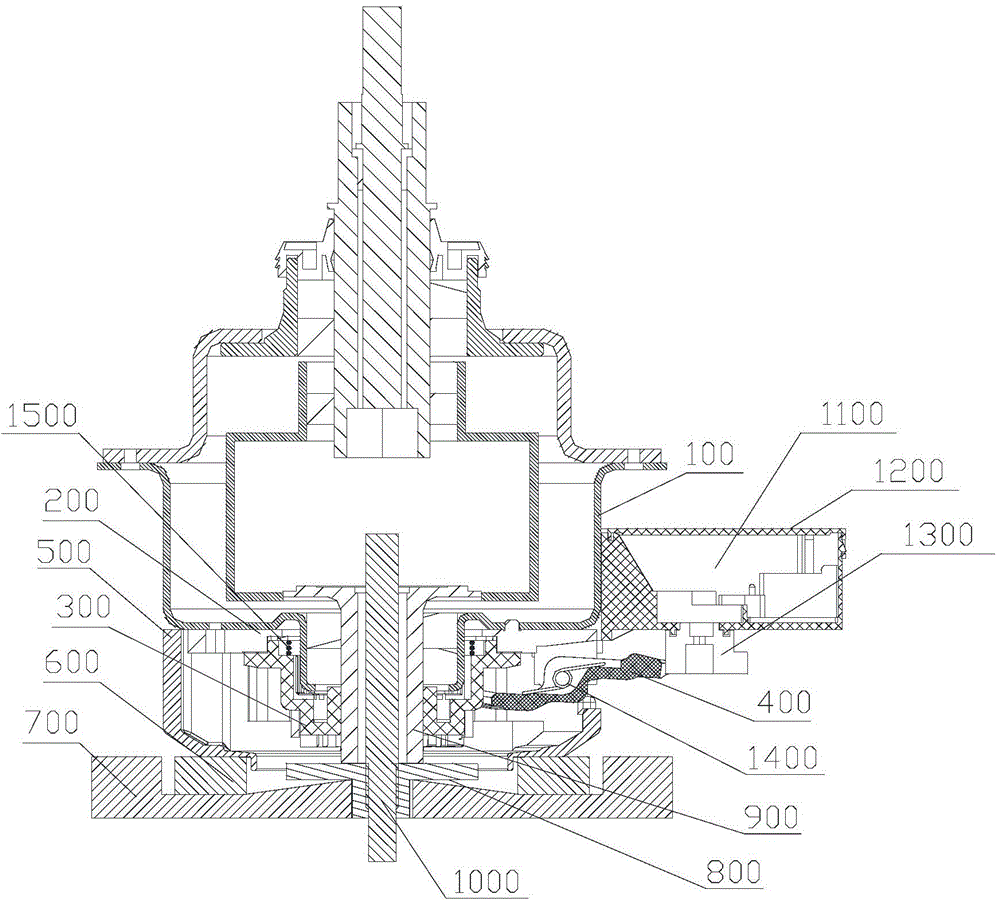

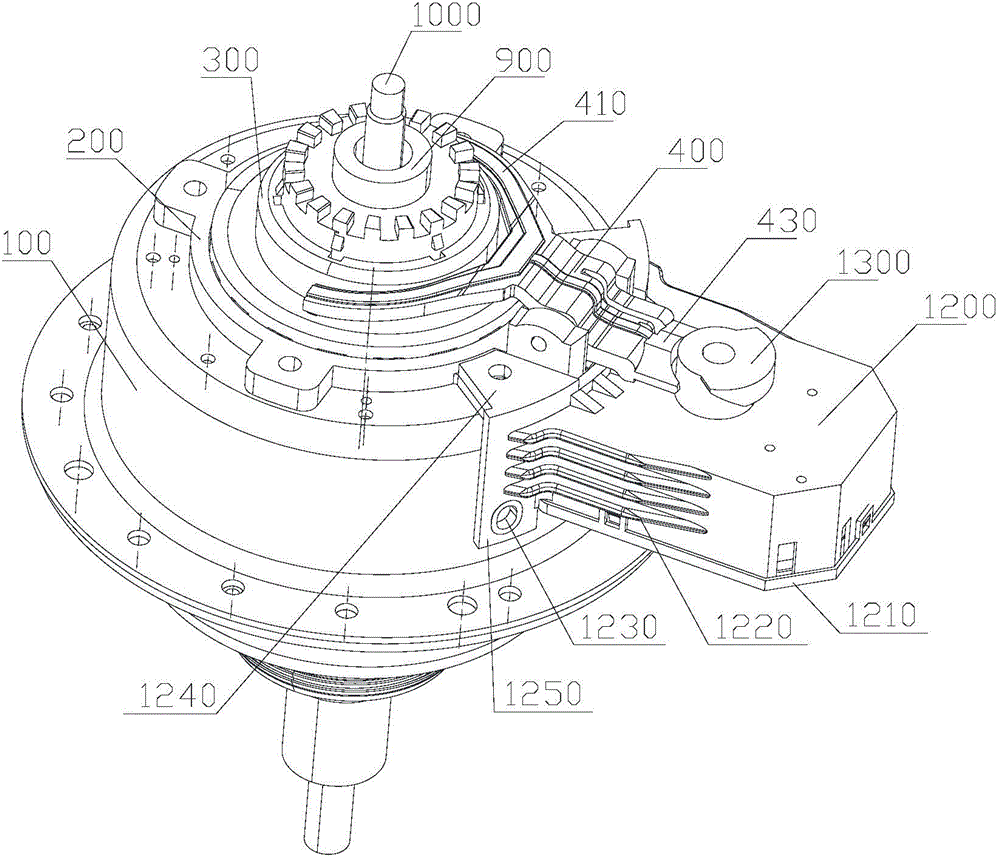

[0044] Such as Figure 3 to Figure 6 As shown, a deceleration clutch clutch driving device described in this embodiment includes a driving motor 1100, a driving wheel 1300 and a shift fork lever 400, the driving wheel 1300 is installed on the motor shaft of the driving motor 1100, and the circumference of the driving wheel 1300 is provided with supports The support surface has a height difference in the axial direction. The shift fork lever 400 is a lever structure, and the middle part is provided with a fixed fulcrum 420. The head of the shift fork lever 400 is a shift fork 410, and the shift fork 410 is located below the clutch sleeve 300. The spring 1500 controls the up and down movement of the clutch sleeve 300 together. The tail of the shift fork lever 400 is the driving end 430, and the driving end 430 is provided with a sliding contact surface, which is slidingly matched with the supporting surface; the driving motor 1100 drives the driving wheel 1300 to rotate, and the ...

Embodiment 2

[0058] Such as Figure 2 to Figure 3 As shown, a clutch drive installation structure is introduced in this embodiment. The clutch drive includes a drive motor 1100, a drive wheel 1300 and a fork lever 400. The drive wheel 1300 is installed on the output shaft of the drive motor 1100. The drive motor 1100 is fixedly installed on the housing 100 of the deceleration clutch. Preferably, the driving motor 1100 is installed in the installation cover 1200 , and the installation cover 1200 is fixed on the casing 100 .

[0059] The installation cover 1200 is composed of a hollow cover for the drive motor 1100. One side of the installation cover 1200 is an installation side wall, and the installation side wall is provided with an outwardly protruding installation flange 1250. The mounting flange 1250 is detachably connected to the shell 100 via bolts.

[0060] Such as image 3 As shown, the installation side wall of the installation cover 1200 and the installation flange 1250 are bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com