Electric auxiliary lock

An electric assist and latch technology, applied in the field of rail car door locks, can solve the problems of loud noise, falling comfort bar, complex structure, etc., and achieve the effect of reducing weight, ensuring strength, and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing and by specific embodiment, and following embodiment is only descriptive, not limiting, can not limit protection scope of the present invention with this.

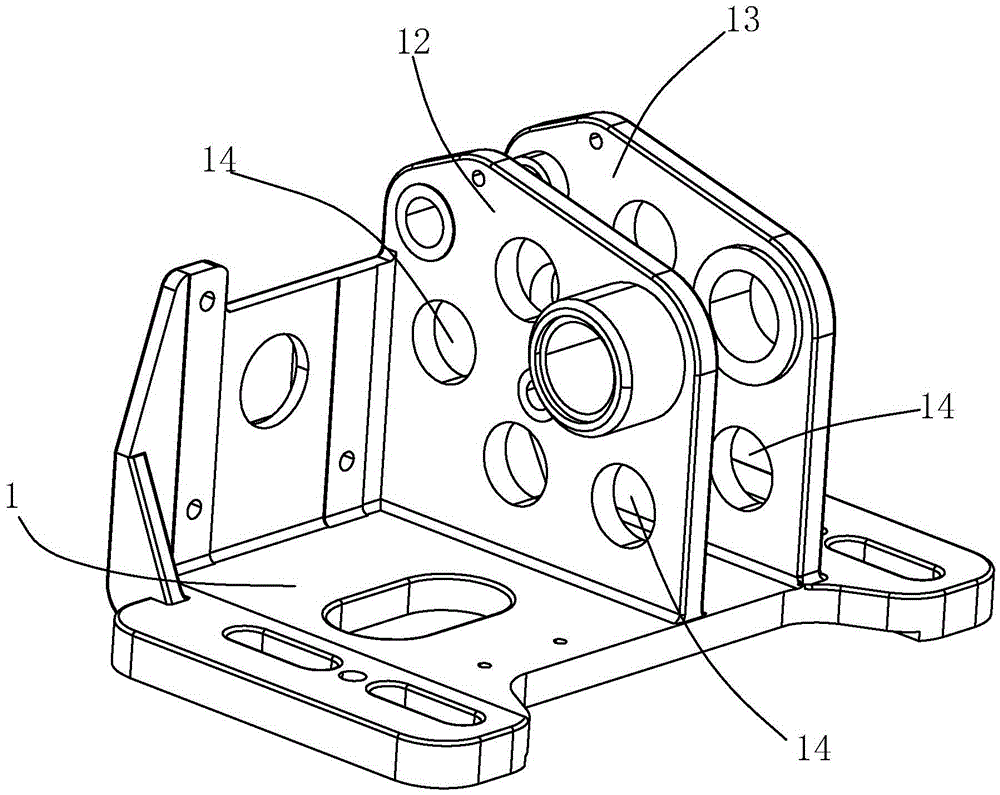

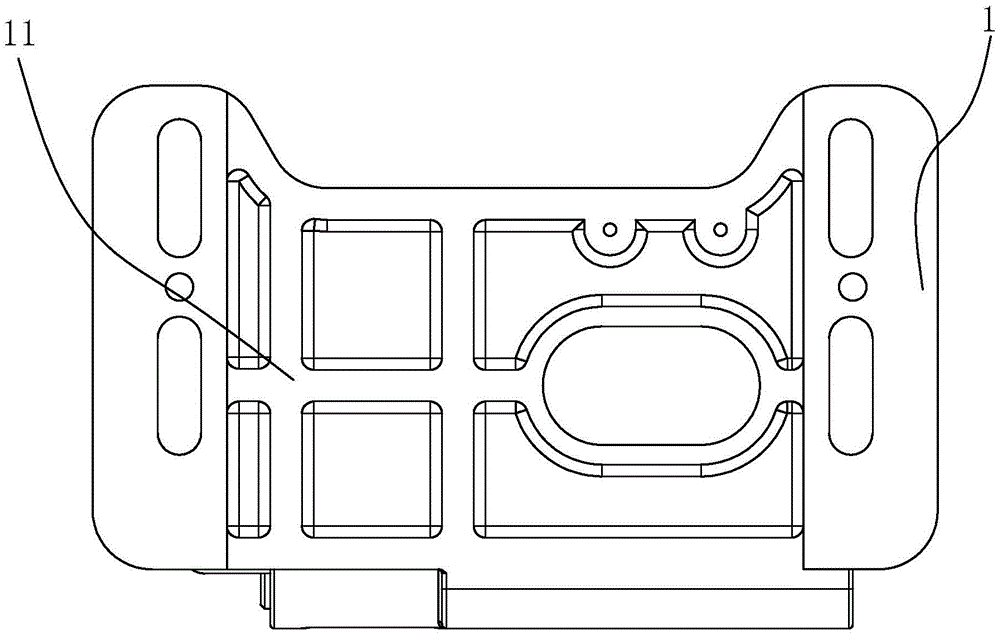

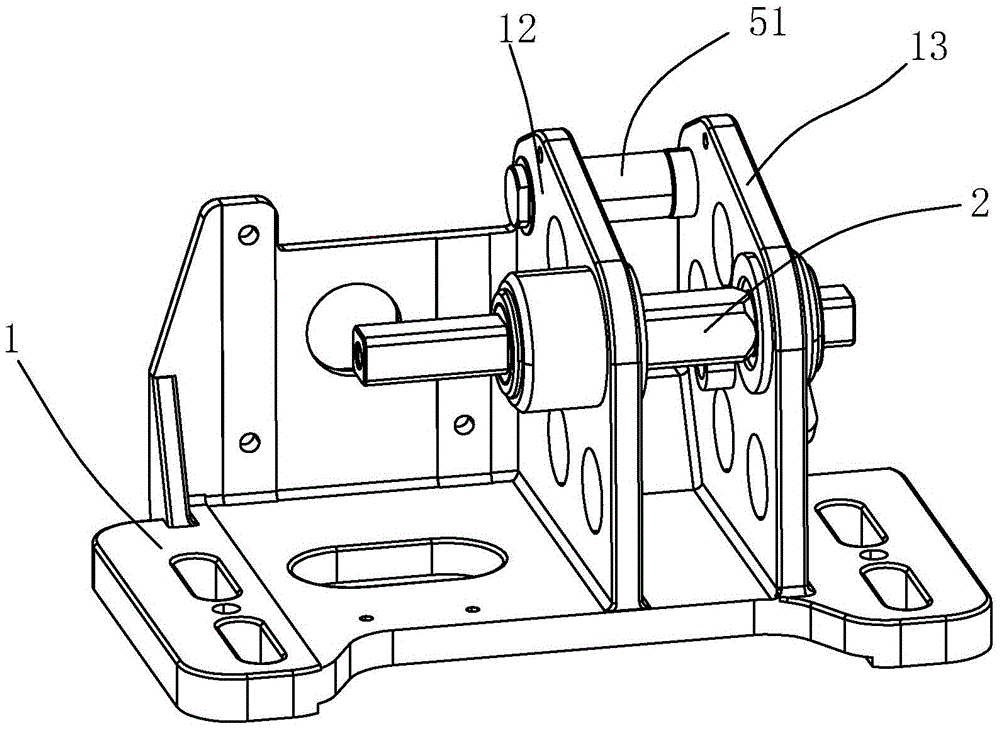

[0036] An electric auxiliary lock, including a base plate 1, on the bottom of the base plate 1 is provided with grid reinforcement ribs 11, which avoids unfavorable factors such as air holes, trachoma, and deformation during casting, and ensures the original structure while reducing weight. While having high strength, it is more convenient for later machining and assembly, and at the same time, the installation contact surface of the overall lock is optimized, that is, when in contact, it can cooperate with the concave surface between the reinforcing ribs, reducing the difficulty of cooperation.

[0037] Refer to attached figure 1 , 2 , is a schematic diagram of the base plate 1, a first positioning plate 12 and a second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com