High-temperature-resistant draught fan

A technology with high temperature resistance and fan, applied in the direction of mechanical equipment, machine/engine, liquid fuel engine, etc., can solve the problems of fast heat conduction, easy to burn the motor, low cooling efficiency, etc., achieve low production cost, overall standardization and beauty, Versatile Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

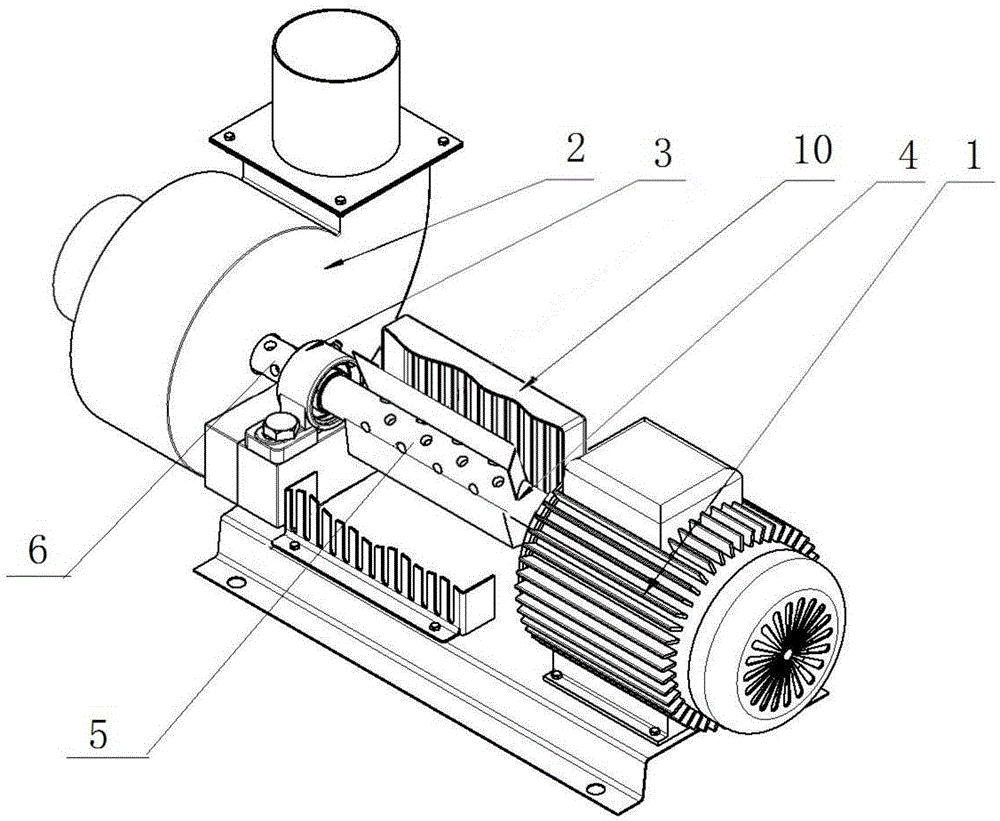

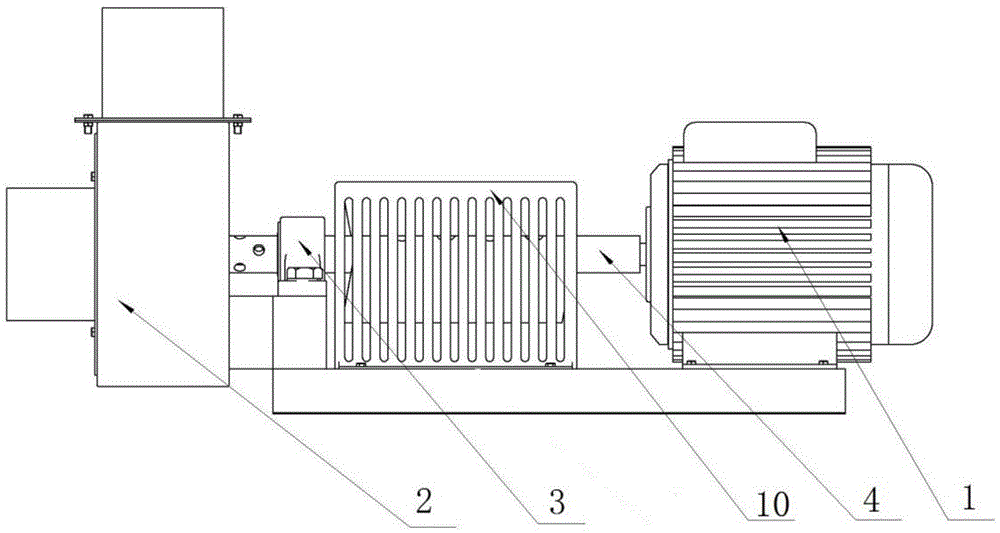

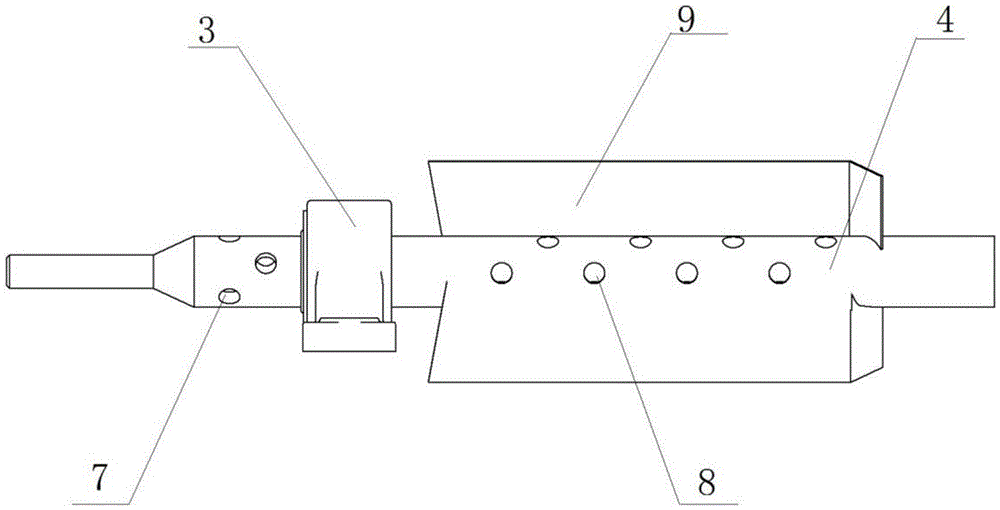

[0033] like figure 1 — Figure 7 Shown: a high temperature resistant fan is composed of a motor 1, an impeller device 2, a transmission shaft and a bearing seat 3 installed on the machine base. The transmission shaft is a hollow transmission shaft 4. The hollow transmission shaft 4 is hollow inside and on the shaft body. There are several air inlets 5 and air outlets 6, and the air outlet 6 is opened on the shaft wall near one end of the impeller device 2, and the hollow drive shaft 4 passes through the bearing seat 3 to connect the motor 1 and the impeller device 2, and the air outlet 6 is. The air outlet holes 7 are specifically distributed with 6 or 6 to 12 air outlet holes 7 in a plum blossom shape, and the air inlet ports 5 are 24 air inlet holes 8, and each 4 is a vertical row and is distributed in parallel on the hollow transmission shaft 4. On the axial surface, the hollow drive shaft 4 is provided with 2 or 2 to 4 pieces of wind turbine blades 9 and is symmetrically ...

Embodiment 2

[0036] like Figure 8 , Figure 9 , Figure 10 Shown: the air inlet 5 on the hollow drive shaft 4 in Example 1 is a long slot 11, the outer opening of the long slot 11 is larger than the inner opening, and the number of the long slot 11 There are two or more, such as four, the elongated slot 11 is parallel to the axis of the hollow transmission shaft 4, and the position of the elongated slot 11 is opened symmetrically with the axis as the axis, so there is no need to install it on the hollow transmission shaft 4 The tornado blades 9 and the safety protection cover 10 increase the air intake area of the air inlet 5, thereby increasing the overall air intake volume, which can effectively improve the air intake rate, and can achieve cooling protection without the assistance of the tornado blades 9. The effect of the motor 1, and after the tornado blades 9 are canceled, the overall standardization of the fan is strong and beautiful, the working noise is low, and the safety and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com