Automatic steel ball assembly machine for plane bearing

A plane bearing, automatic technology, applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve problems such as sticking, steel ball falling, time-consuming and labor-intensive problems, and achieve high efficiency, convenient mold replacement, and high degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

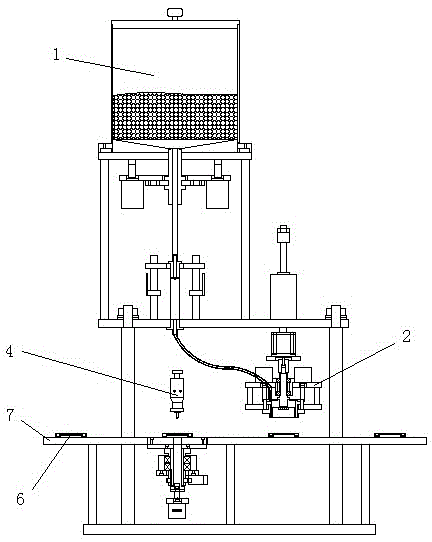

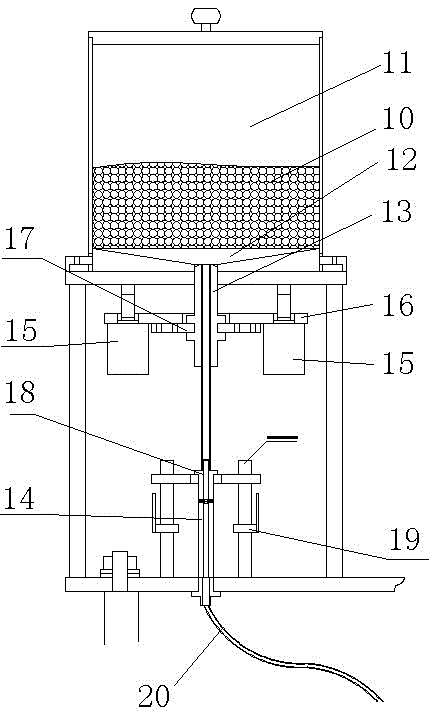

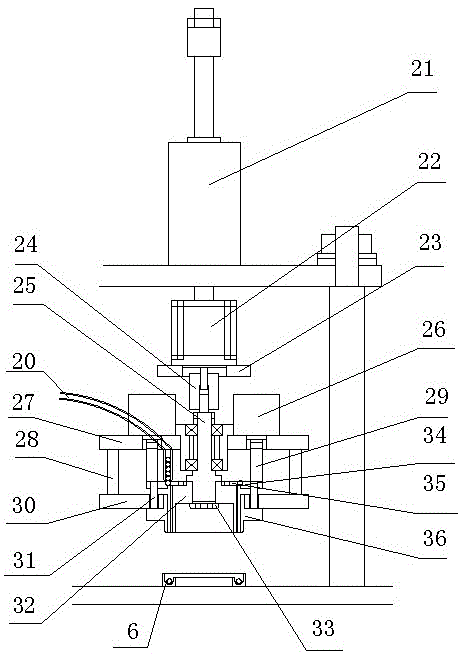

[0032] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0033] An automatic steel ball loading machine for plane bearings is composed of a bearing transfer mechanism 5, a grease injection mechanism 4, a ball lowering mechanism 1 and a ball distributing mechanism 2, all of which are installed on a working table 7.

[0034] Such as figure 1 The shown plane bearing automatic steel ball loading machine is arranged on a worktable 7, and a bearing transfer mechanism 5 is installed on the worktable. Such as Figure 5 with Image 6 As shown, the bearing transfer mechanism includes a pair of guide rails 58, a mobile platform is installed on the guide rails, a third stepping motor 56 is arranged on the mobile platform, and the third stepping motor 56 drives the rolling wheel 57 to rotate, so that the mobile platform is positioned on the guide rails. Move left and right in the horizontal direction. A telescopic mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com