Content analyzing apparatus

A technology for analyzing device and content, which is applied in measurement device, volume flow measurement device, liquid/fluid solid measurement, etc., can solve the problems of different liquid and gas outlet conditions, great influence on measurement accuracy, and failure to achieve expected results, etc. Achieve the effect of small pressure loss, high precision and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

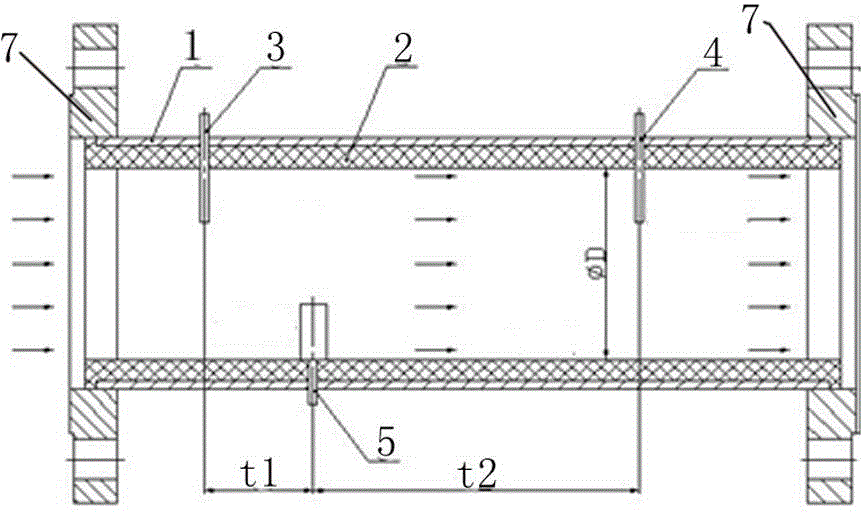

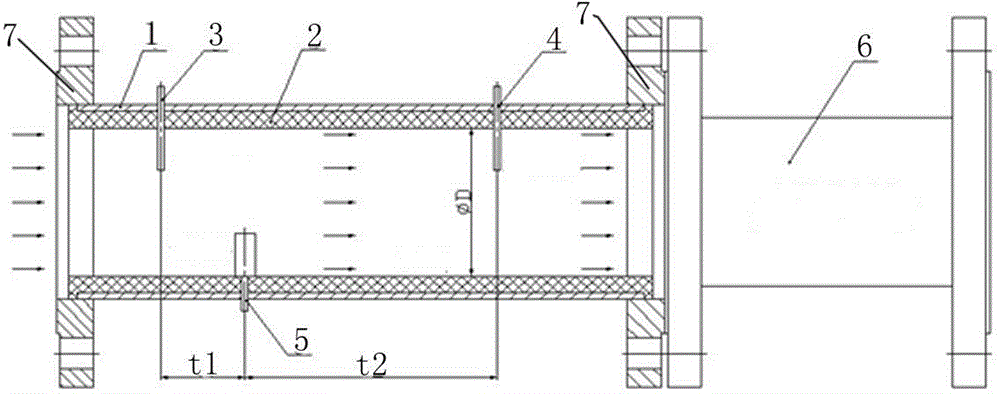

[0016] A content analysis device, a straight tube housing 1 with open ends is provided with a heat insulating layer 2 on the inner wall; the upper wall of the housing is provided with two spaced temperature sensors, the front temperature sensor 3 is located at the front, and the rear temperature sensor 3 is located at the front. The sensor 4 is arranged at the rear; a heating element 5 is arranged on the lower wall of the casing, and the heating element is located between the front and rear temperature sensors.

[0017] The inner diameter of the straight pipe shell is D, the distance t1 between the front temperature sensor 3 and the heating element 5 is 0.5 to 5 times the inner diameter D; the distance t2 between the rear temperature sensor 4 and the heating element 5 is 10 times to 30 times the inner diameter D .

[0018] Flanges 7 are provided at both ends of the straight pipe housing.

[0019] When the present invention is used, the front end is the inlet of the oil-water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com