C/S structure-based fabric defect detection information management system and method thereof

A technology of detection information and management system, which is applied in the field of fabric defect detection information management system based on C/S structure, can solve problems such as low automation, low accuracy, and work waste, so as to reduce labor intensity, improve efficiency, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

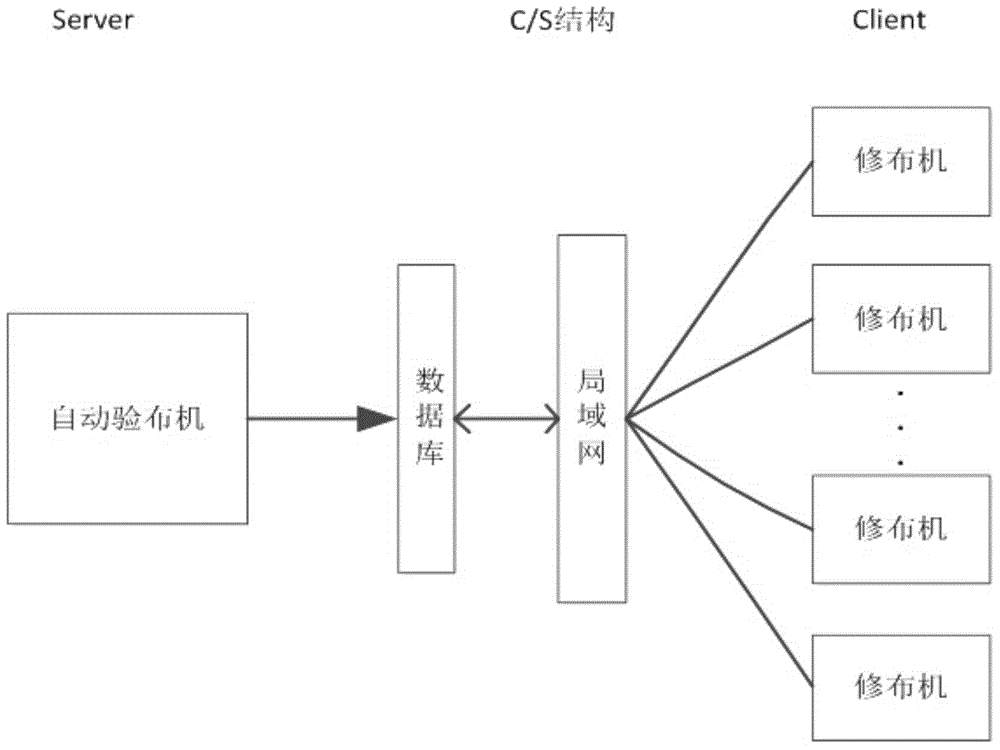

[0019] In the textile production industry, the detection and identification of fabric defects is a key link in fabric quality control, which is of great significance. Repairing and cutting of defects is an effective means to reduce the loss of defective products. The invention provides a fabric defect detection information management system and method based on a C / S structure. The system mainly includes two parts: one is an automatic cloth inspecting machine, and the other is a semi-automatic cloth repairing machine.

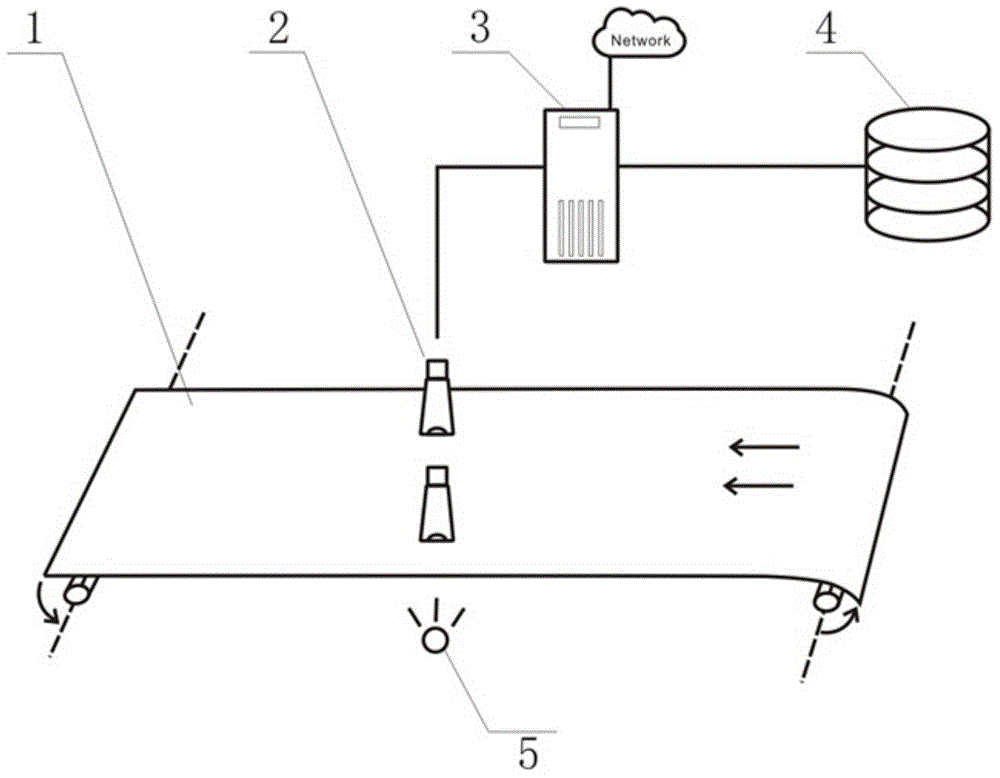

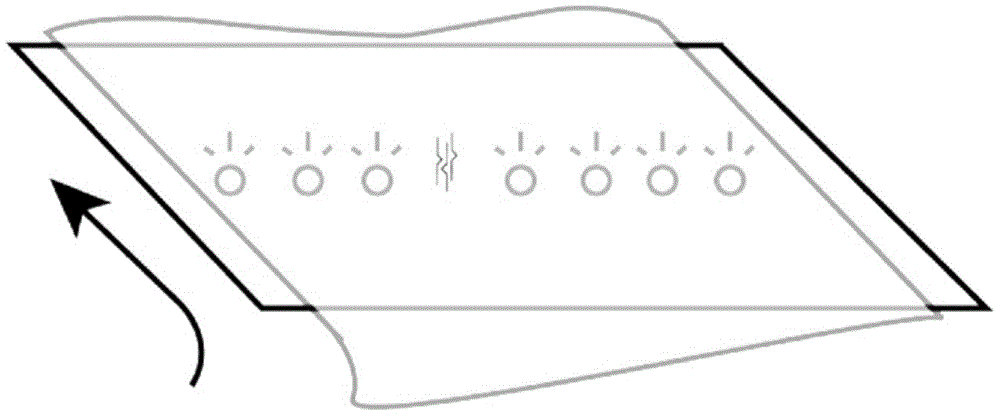

[0020] Such as figure 1 As shown, the automatic cloth inspection machine adopts two high-definition linear array CCD2 and bright LED lamp tube 5 to collect image data, and runs the defect recognition algorithm in the server computer 3 to judge the defect position in real time and save the corresponding cloth record to the database Among them, the server computer 3 is connected to the local area network, and forms a C / S structure with the cloth repairing machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com