Power equipment maintenance coding management system in transformer substation

A technology for power equipment and management systems, applied in information technology support systems, data processing applications, instruments, etc., can solve problems such as personal safety hazards, economic losses, and confusion in power maintenance for power maintenance personnel, so as to avoid docking errors and reduce errors. rate, the effect of timely data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

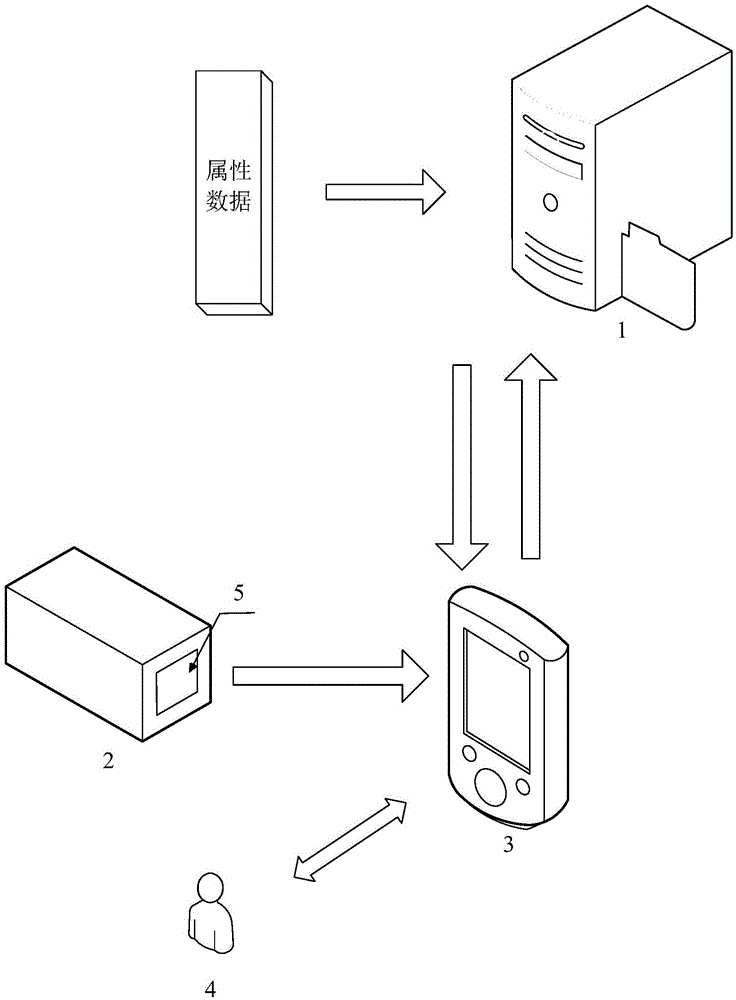

[0037] A maintenance code management system for power equipment 2 in a substation, such as figure 1 As shown, it includes a feature identification tag 5, a network server 1, and a mobile device 3 connected to the network server 1. The feature identification tag 5 is set on the power equipment 2 in the substation, and the network server 1 stores the information of each power equipment 2. Attribute data, the device code corresponding to the electric device 2 is stored on the feature identification tag 5. After the mobile device 3 establishes a data connection with the feature identification tag 5, it learns the device code of the power device 2, and then according to the device code, obtains / Modify the attribute data corresponding to the power equipment 2 in the network server 1, and conduct unified management on the materials in the substation, prevent the loss and damage of the data of the power equipment, and ensure the integrity of the power equipment. In the process of pow...

Embodiment 2

[0052] The similarities between this embodiment and the first embodiment will not be described, and only the differences will be described.

[0053] The significant difference between the present embodiment and the first embodiment is that the feature recognition label 5 in this embodiment is a two-dimensional code, and the label generating unit is a barcode printer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com