SOT23 lead frame and packaging process flow thereof

A technology of SOT23 and lead frame, applied in the field of SOT23 lead frame and its packaging process, can solve the problems of multi-area, middle-rib area and gap waste between adjacent two outer pins, low frame utilization rate, etc. The effect of improving efficiency and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

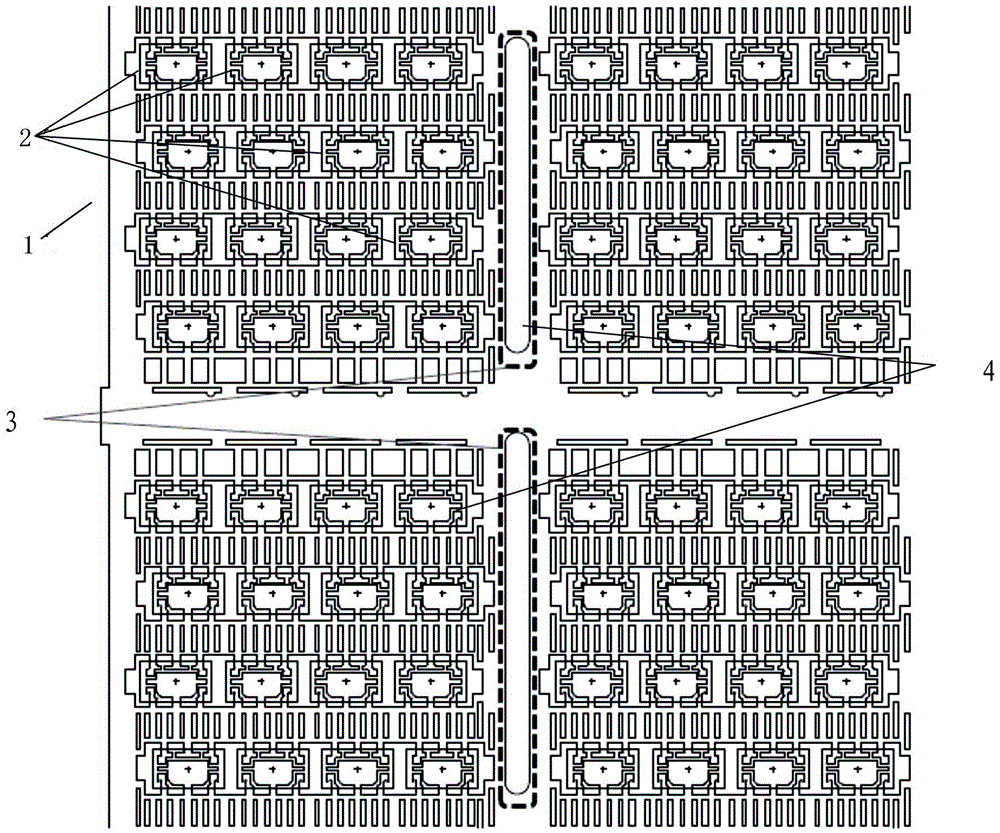

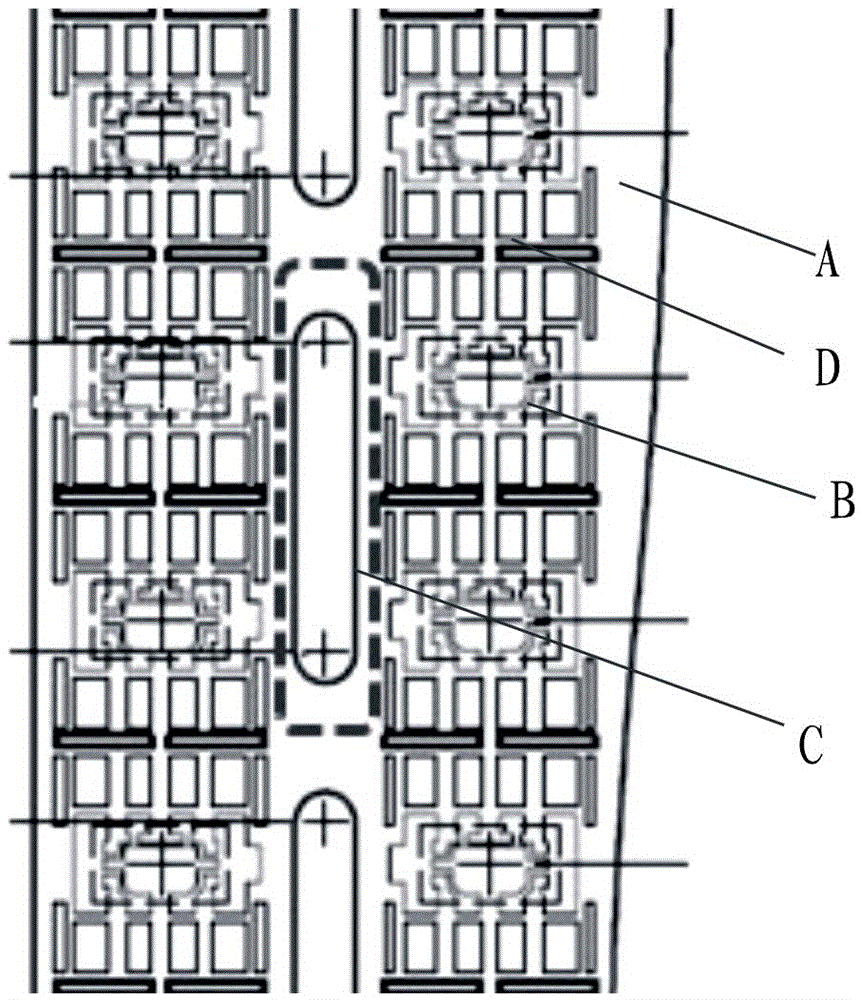

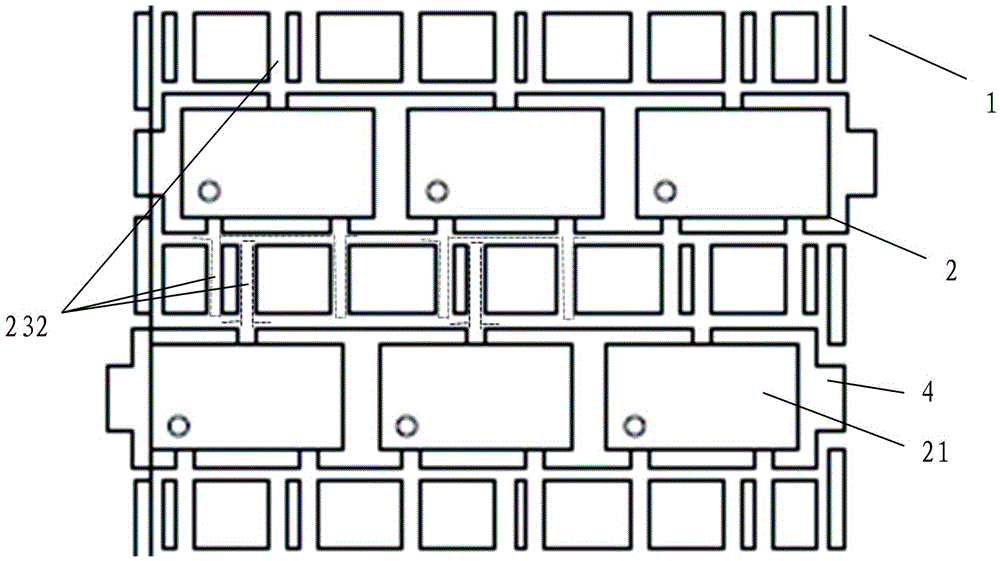

[0036] like Figures 2 to 15 As shown, the SOT23 lead frame structure of the present invention includes a frame 1, a plurality of installation units 2 arranged on the frame 1, and each installation unit 2 includes a base island 21, and leads arranged on two opposite sides of the base island 21. pins 23, each of which pins 23 includes inner pins 231 (as Figure 8 As shown) and outer pins 232, the plurality of installation units 2 are arranged on the frame 1 in X rows and XY columns, and the outer pins 232 of two adjacent rows of installation units 2 are arranged to cross and stagger each other, and A column of runners 3 is provided for every N rows of installation units 2 on the frame 1, and the N is not less than 2. The installation unit 2 close to the runners 3 is provided with a glue injection port 4 on the side facing the runners 3. A dambar-5 is arranged between two adjacent outer pins 232 of the same installation unit 2, and a dambar-6 is arranged between adjacent outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com