Battery frame tray with water cooling plate and processing method of battery frame tray

A battery frame and water-cooled plate technology, which is applied to secondary batteries, battery pack parts, circuits, etc., can solve the problems of unfavorable waterproof and dustproof, solve the problems of sealing and heat dissipation, reduce weight, and simplify the process steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

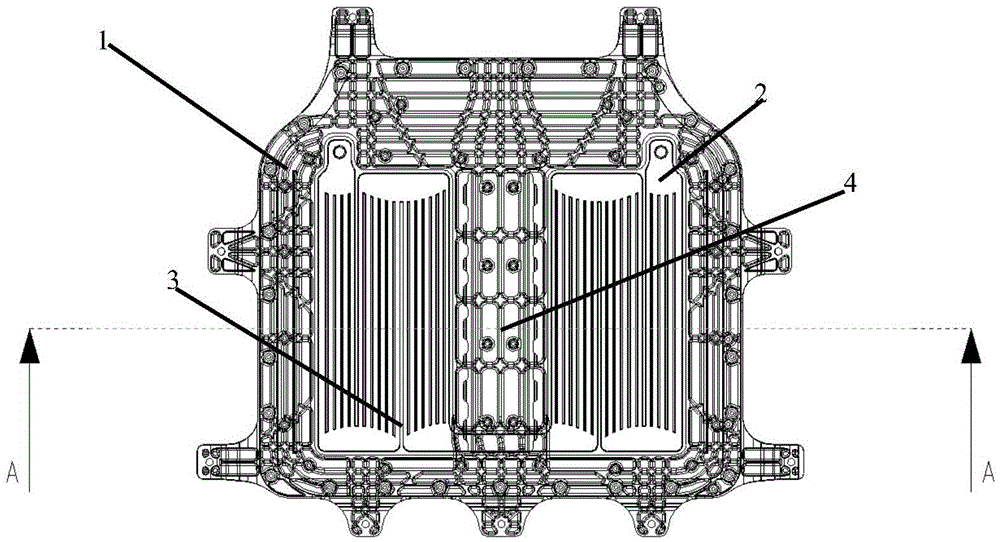

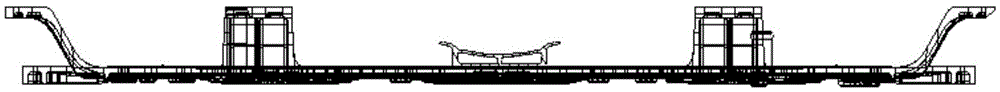

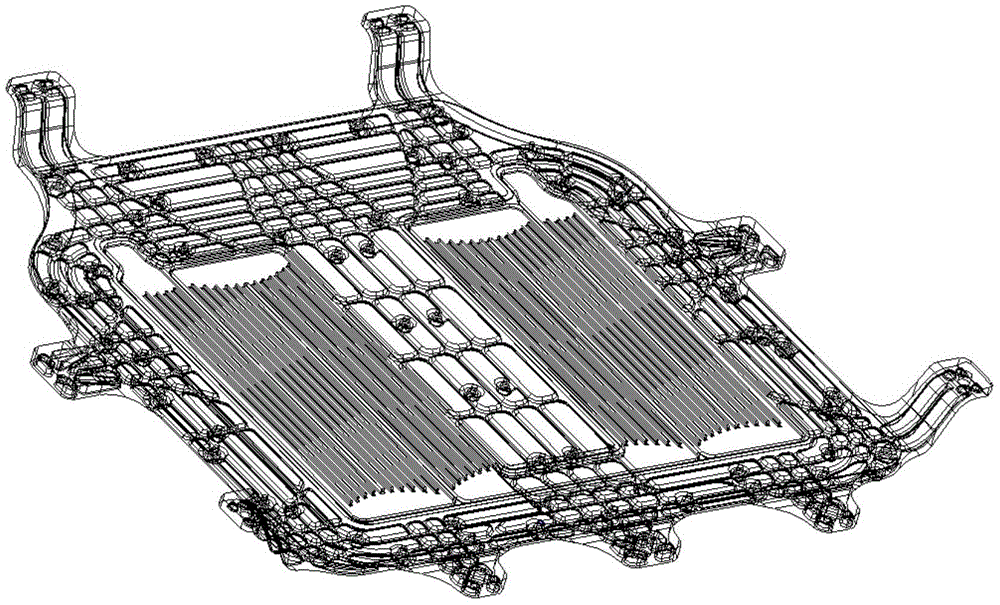

[0034] A battery pack with a water-cooled plate, including a battery frame, a water-cooled cover plate 2, and a middle beam 4, all of which are made of aluminum alloy to reduce weight. The battery frame includes a bottom tray 1, the lower surface of the bottom tray 1 has rib partitions 3, the water-cooling cover plate 2 is U-shaped, and the two sides are used to arrange water channels, and the middle beam 4 is fixed in the middle to fix the battery pack. The two ends of the rib partition 3 are against the water-cooling cover plate 2 and the rib partition 3 respectively, forming a water channel in the middle, the water channel is in a circuitous shape, and there are multiple parallel water channel ribs in the water channel.

[0035] There are two ways to connect the bottom tray 1, the water-cooling cover plate and the water channel rib partition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com