A pre-lithiation treatment process and device for a silicon-based negative electrode

A technology of silicon-based negative electrode and processing technology, which is applied in the field of lithium-ion batteries, can solve the problems of low initial charge and discharge efficiency of silicon-carbon negative electrodes, and achieve the effects of improving initial charge and discharge efficiency, avoiding precipitation, and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

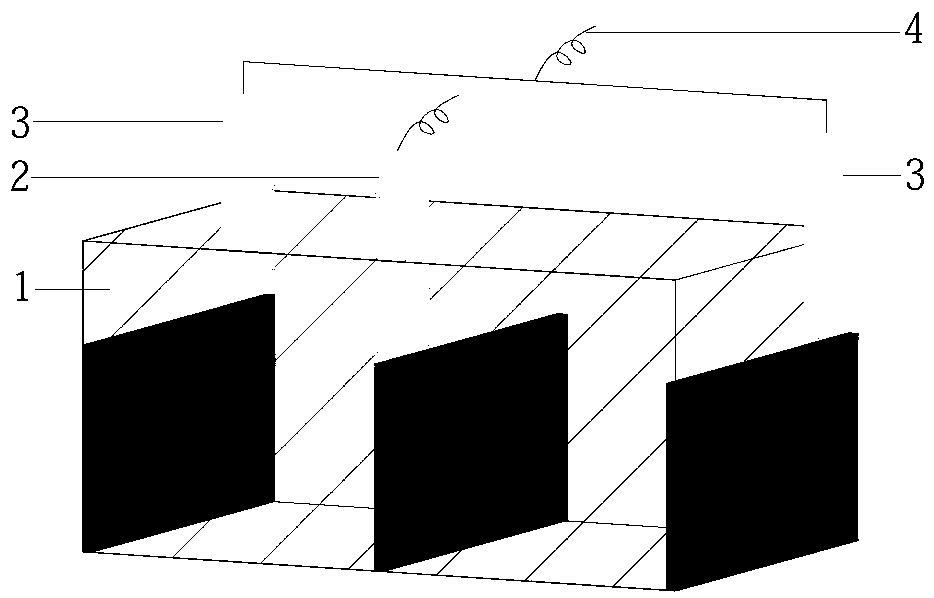

[0031] A pre-lithiation treatment device for a silicon-based negative electrode, comprising an electrolytic cell 1, a working electrode 2, a counter electrode 3 and a wire 4, wherein the working electrode 2 (silicon-based negative electrode) is vertically located in the middle of the electrolytic cell 1, and the left side is connected to the side of the electrolytic cell The upper side is connected to the wire 4; the counter electrode 3 (metal lithium sheet) is two pieces, which are respectively vertically attached to the front and rear walls of the electrolyte, the right side is attached to the side wall of the electrolytic tank, and the upper side is connected to the same wire. Wire 4 is connected.

[0032] A pre-lithiation treatment process for a silicon-based negative electrode, the steps are as follows:

[0033] (1) Homogenize 650mAh / g silicon carbon powder, conductive agent SP, hydroxymethyl cellulose (CMC) and styrene-butadiene rubber (SBR) according to the mass ratio o...

Embodiment 2

[0045] A pre-lithiation treatment device for a silicon-based negative electrode, the structure of which is basically the same as that of Example 1.

[0046] A pre-lithiation treatment process for a silicon-based negative electrode, the steps are as follows:

[0047] (1) Homogenize 650mAh / g silicon carbon powder, conductive agent SP, hydroxymethyl cellulose (CMC) and styrene-butadiene rubber (SBR) according to the mass ratio of 90:5:5:5. Coating on copper foil, one side coating surface density is 2mg / cm 2 , made of silicon-based negative electrode;

[0048] (2) In a glove box where the water vapor content is controlled to be less than 1ppm and the oxygen content is less than 1ppm, use an electrolysis device equipped with a lithium-intercalated electrolyte, use a metal lithium sheet as a counter electrode, and a silicon-based negative electrode as a working electrode. Electrodeposit lithium metal;

[0049] (3) Electrodeposition of lithium metal: In lithium intercalation elect...

Embodiment 3

[0059] A pre-lithiation treatment device for a silicon-based negative electrode, the structure of which is basically the same as that of Example 1.

[0060] A pre-lithiation treatment process for a silicon-based negative electrode, the steps are as follows:

[0061] (1) Homogenize 650mAh / g silicon carbon powder, conductive agent SP, hydroxymethyl cellulose (CMC) and styrene-butadiene rubber (SBR) according to the mass ratio of 90:5:1:1. Coating on copper foil, one side coating surface density is 2mg / cm 2 , made of silicon-based negative electrode;

[0062] (2) In a glove box where the water vapor content is controlled to be less than 1ppm and the oxygen content is less than 1ppm, use an electrolysis device equipped with a lithium-intercalated electrolyte, use a metal lithium sheet as a counter electrode, and a silicon-based negative electrode as a working electrode. Electrodeposit lithium metal;

[0063] (3) Electrodeposition of lithium metal: In lithium intercalation elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com