Lithiation treatment method of diaphragm and diaphragm material treated by using lithiation treatment method

A treatment method and diaphragm technology, applied to electrochemical generators, electrical components, circuits, etc., can solve the problems of low initial charge and discharge efficiency, high porosity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

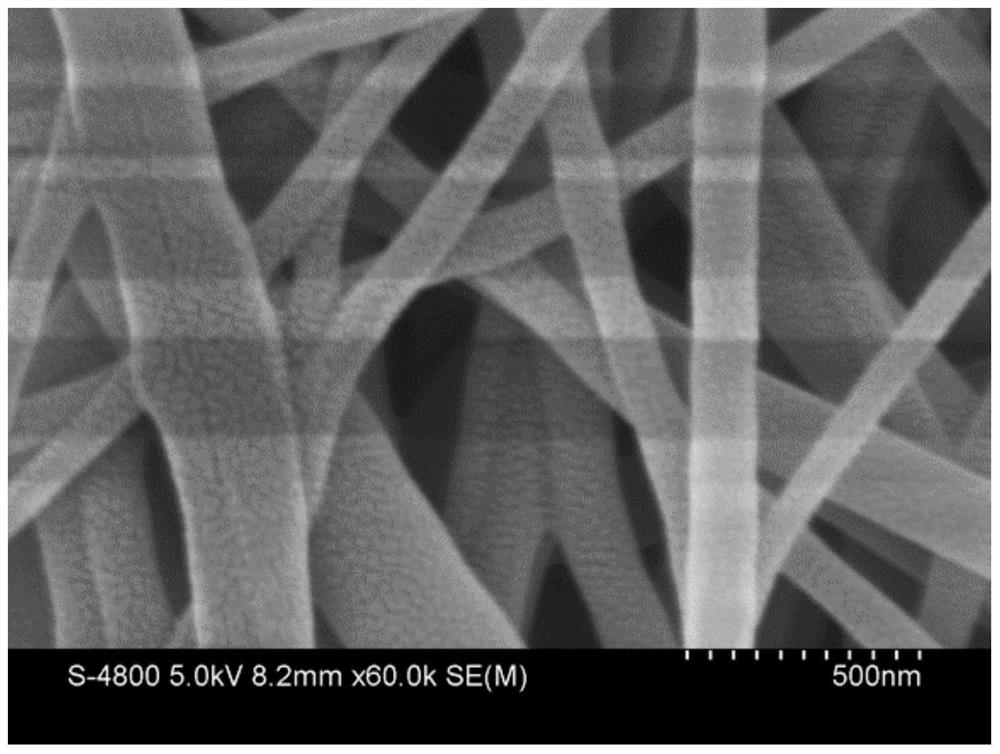

Image

Examples

Embodiment 1

[0035]The lithiation treatment method of a diaphragm, steps below:

[0036]The diaphragm was soaked with a dilute hydrochloric acid with a weight percentage of 0.1%, and then cleaned with distilled water to a pH test paper, it was shown to be 6 (measurement standard: 1 part separator was soaked in 9 parts of distilled water for 10 minutes after measurement). After the drying was taken, it was soaked in a lithium sulfate solution having a weight percentage of 0.1%, and heated to a high temperature of 60 ° C, heat insulation 100 h. Take it dry. The weight of the silane coupling agent is sprayed on the diaphragm using the weight percentage of 1% by weight, and the load amount of the silane coupling agent on the membrane is 1 g / m.2. The diaphragm was taken, about 50 ° C, 0.05 MPa vacuum, dry 48 h.

[0037]The diaphragm material treated by this method can greatly increase the first charge and discharge efficiency of the lithium ion battery. For example, 18650 lithium iron phosphate batteries...

Embodiment 2

[0040]The lithiation treatment method of a diaphragm, steps below:

[0041]The diaphragm was soaked with a weight percentage of 20% by weight, and then cleaned with distilled water to a pH test paper, it was shown to be 8 (measurement criteria: 1 part of the diaphragm was soaked for 10 minutes after 9 parts of distilled water). After the drying is taken, the soaking of it is then immersed in a lithium dihydroduct lithium hydrogen phosphate solution in weight, and the seal is warmed to a high temperature of 150 ° C (100 degrees, water will boil, more than 100 degrees of treatment temperature needs to be sealed), heat 1h. Take it dry. The weight of the silane coupling agent is sprayed on the membrane using a weight percentage of 20%, and the load of the silane coupling agent on the membrane is 100 g / m.2. The diaphragm was taken, about 100 ° C, 0.001 MPa vacuum, dry 12h.

[0042]The diaphragm material treated by this method can greatly increase the first charge and discharge efficiency of ...

Embodiment 3

[0044]The lithiation treatment method of a diaphragm, steps below:

[0045]The diaphragm was soaked with a weight percentage of 10% by weight, and then washed with distilled water to the pH test paper to be selected as 7 (measurement criteria: 1 part of the diaphragm was soaked in 9 parts of distilled water for 10 minutes after measurement). After the drying was taken, it was soaked in a lithium nitrate solution having a weight percentage of 5%, and heated to a high temperature of 100 ° C, and held 2 h. Take it dry. The weight of the silane coupling agent was used in weight percentage, and the load capacity of the silane coupling agent on the membrane was 20 g / m.2. The diaphragm was taken, about 80 ° C, 0.01 MPa vacuum, dry 48 h.

[0046]The diaphragm material treated by this method greatly increases the first charge and discharge efficiency of lithium ion batteries. For example, it is made into a 10AH-specific 811 system three-membered aluminum-shell battery, which can increase the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com