Negative electrode material additive and preparation method thereof

A negative electrode material and additive technology, applied in the field of negative electrode material additive and its preparation, can solve the problems of low initial charge and discharge efficiency, unstable metal lithium, practical production obstacles, etc., and achieve the effect of solving the low initial charge and discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Prepare a tetrahydrofuran solution with a pure phosphoric acid concentration of 10% (phosphoric acid 0.28g, tetrahydrofuran 2.5g) in the glove box, stir evenly, slowly add 0.06g of crushed lithium flakes, stir the solution, and wait until the tetrahydrofuran is completely volatilized to obtain lithium phosphate-coated lithium Material.

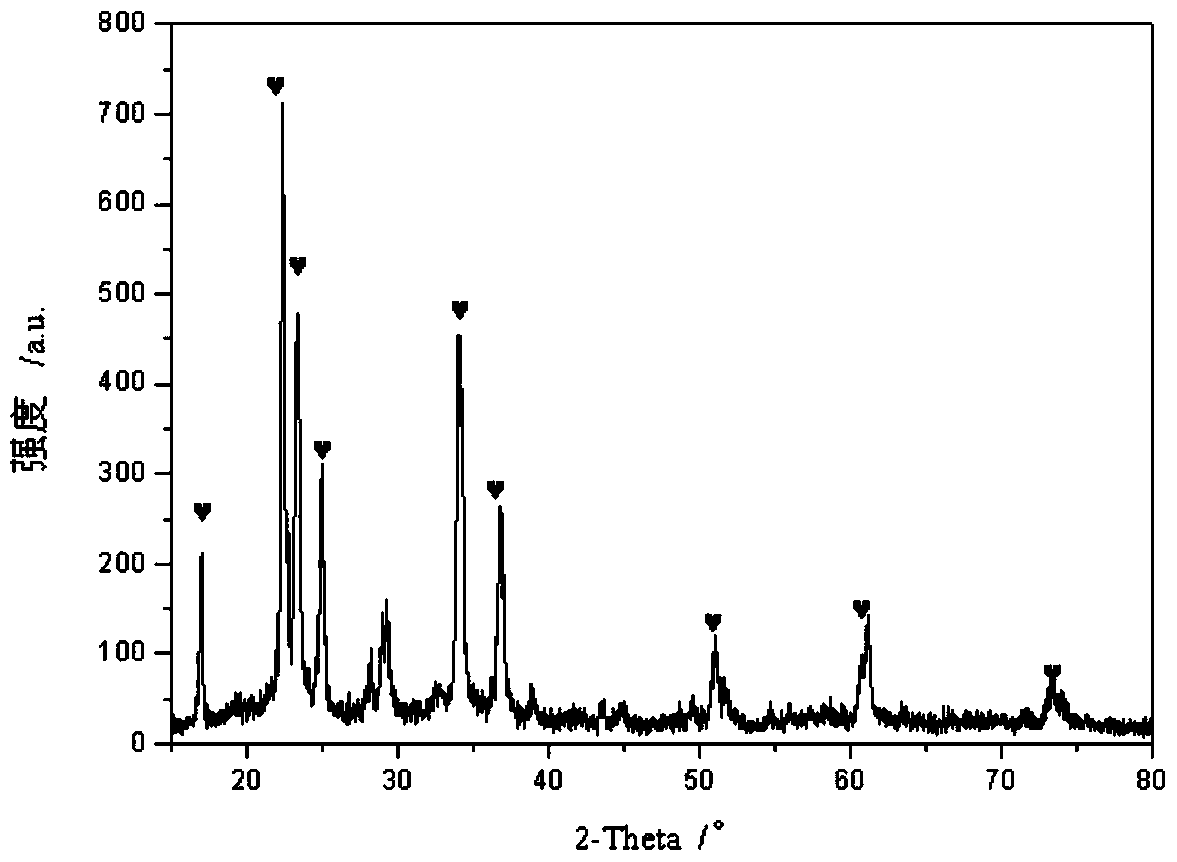

[0028] The lithium phosphate-coated lithium material prepared above was subjected to XRD analysis, and the results were as follows: figure 1 Shown: There is Li in the spectrum 3 PO 4 The existence of characteristic peaks proves that there is Li on the surface of lithium 3 PO 4 The cladding is generated.

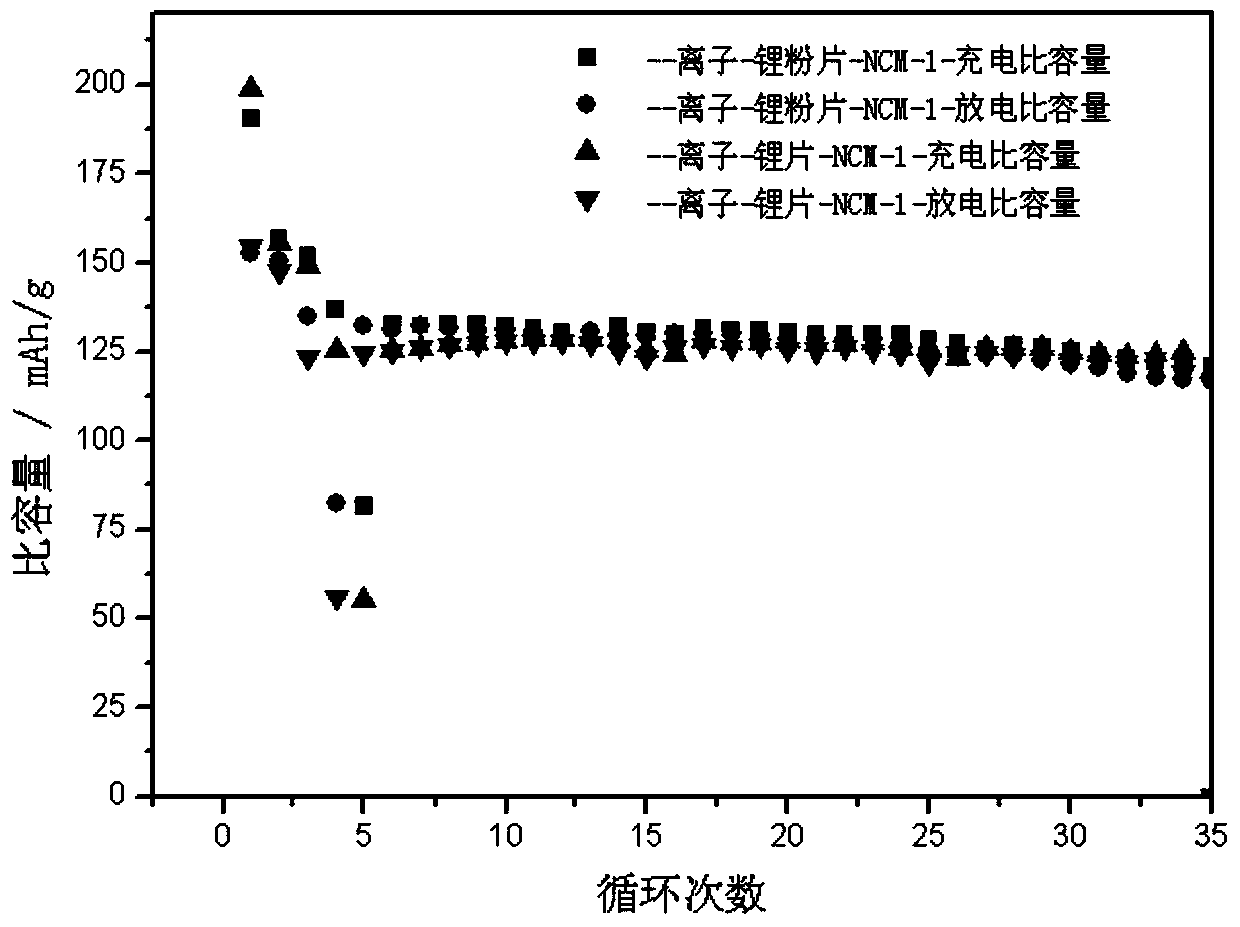

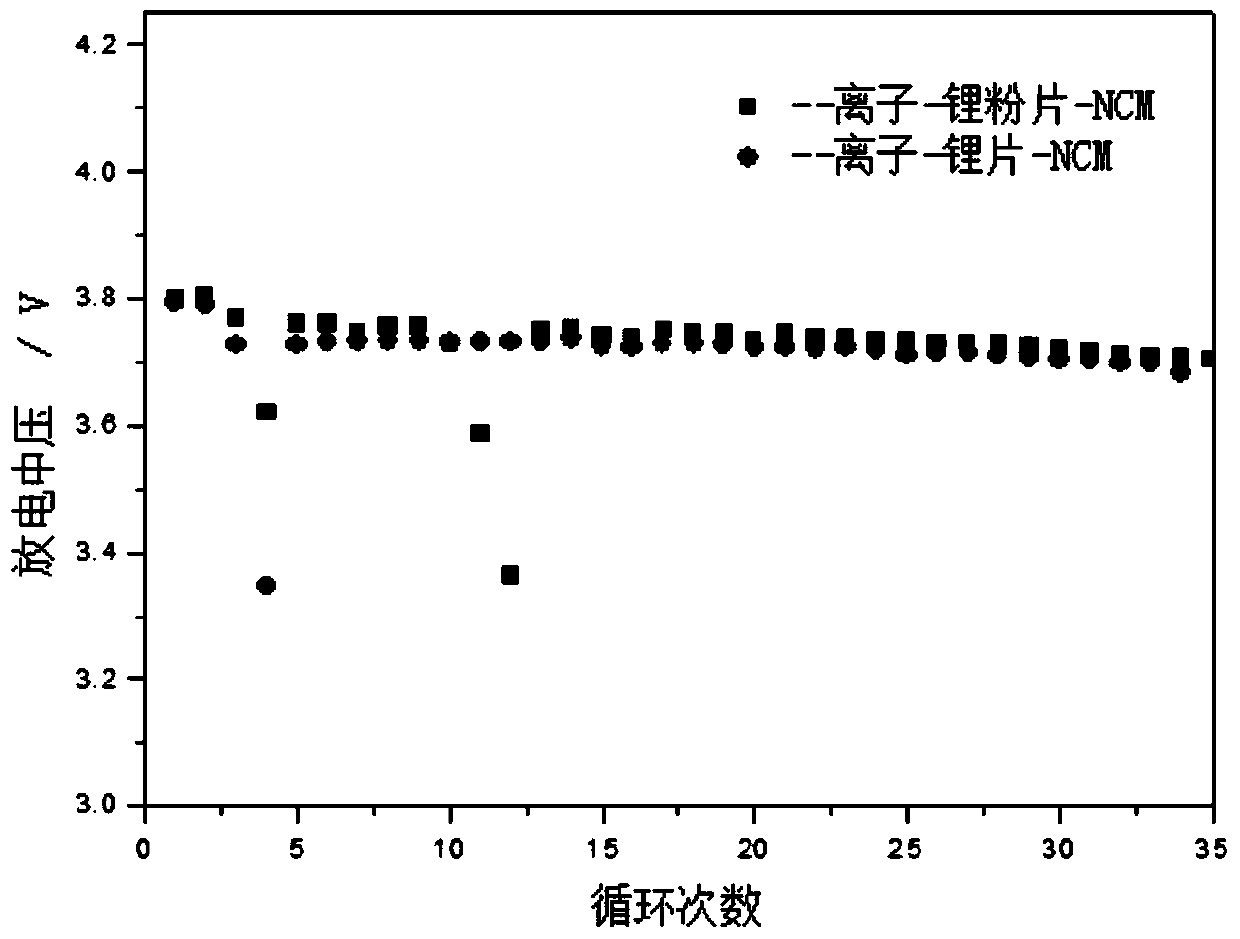

[0029] Electrode preparation: Prepare the slurry according to the ratio of nickel cobalt lithium manganese oxide positive electrode material (NCM) / conductive agent / PVDF=8:1:1, and make the positive electrode sheet after coating, drying and slicing, and the negative electrode sheet is Using the above-mentioned prepared lithium phos...

Embodiment 2

[0036] Using nickel cobalt lithium manganese oxide (NCM) as the positive electrode material, porous silicon as the negative electrode material, adding 10wt% lithium phosphate-coated lithium material (prepared in Example 1), and using lithium hexafluorophosphate carbonate electrolyte and PVDF diaphragm to assemble the battery , the test results of its specific discharge capacity and Coulombic efficiency are as follows Figure 5 shown.

Embodiment 3

[0038] Using nickel cobalt lithium manganese oxide (NCM) as the positive electrode material, porous silicon as the negative electrode material, adding 20 wt% lithium phosphate-coated lithium material (prepared in Example 1), and using lithium hexafluorophosphate carbonate electrolyte and PVDF diaphragm to assemble the battery , the test results of its specific discharge capacity and Coulombic efficiency are as follows Figure 5 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com