Air distribution screen suitably used for storage battery polar plate curing chamber

A pole plate curing and storage battery technology, applied in the field of wind screens, can solve the problems of unreasonable dynamic and static pressure conversion, shortened curing cycle, low long-term reliability, etc., and achieves the effects of good universality, convenient processing and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

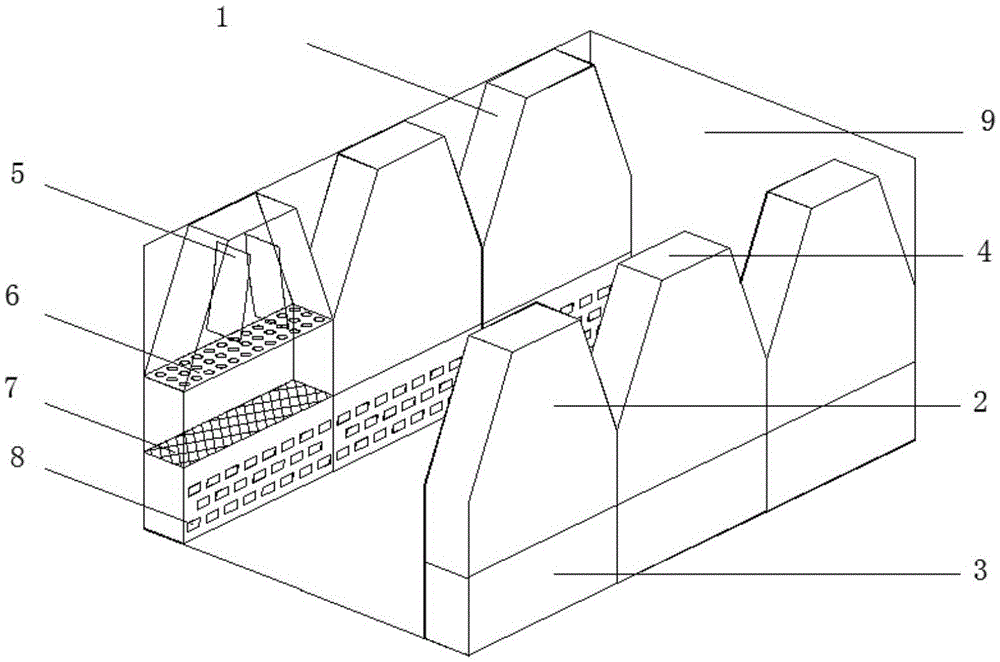

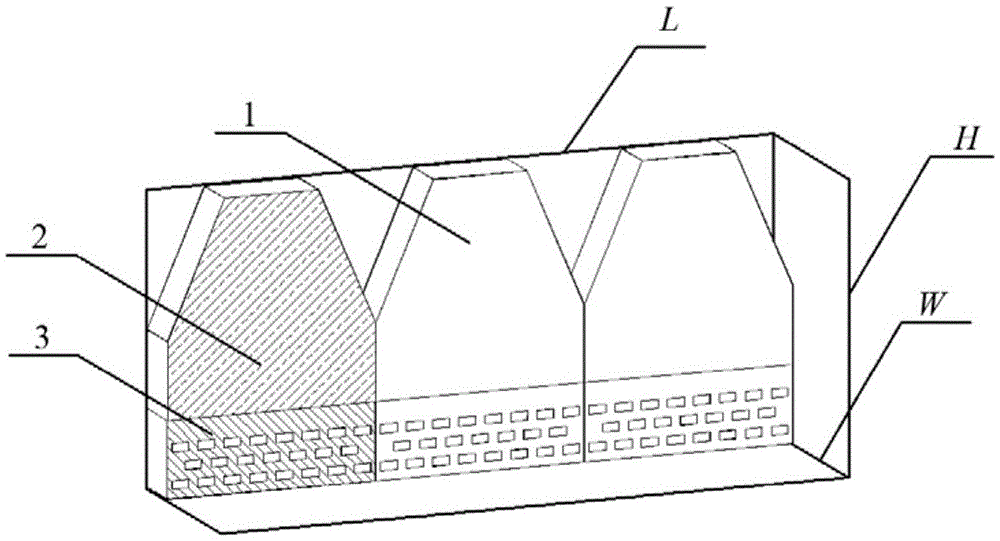

[0063] In this embodiment, the curing room corresponding to the air distribution screen has a height of H=2700mm, a width of W=3700mm, a length of L=6000mm, and an air supply Q of 18000m 3 h -1 , The way of sending and returning air is side sending and top return.

[0064] The upper limit of the air volume q that can be handled by a single air distribution unit is 3500m 3 h -1 , so the number of air distribution units must be greater than 5.14. Therefore, in this embodiment, 6 air distribution units need to be provided, which are arranged symmetrically according to the way of sending and returning air, that is, 3 air distribution units on each side.

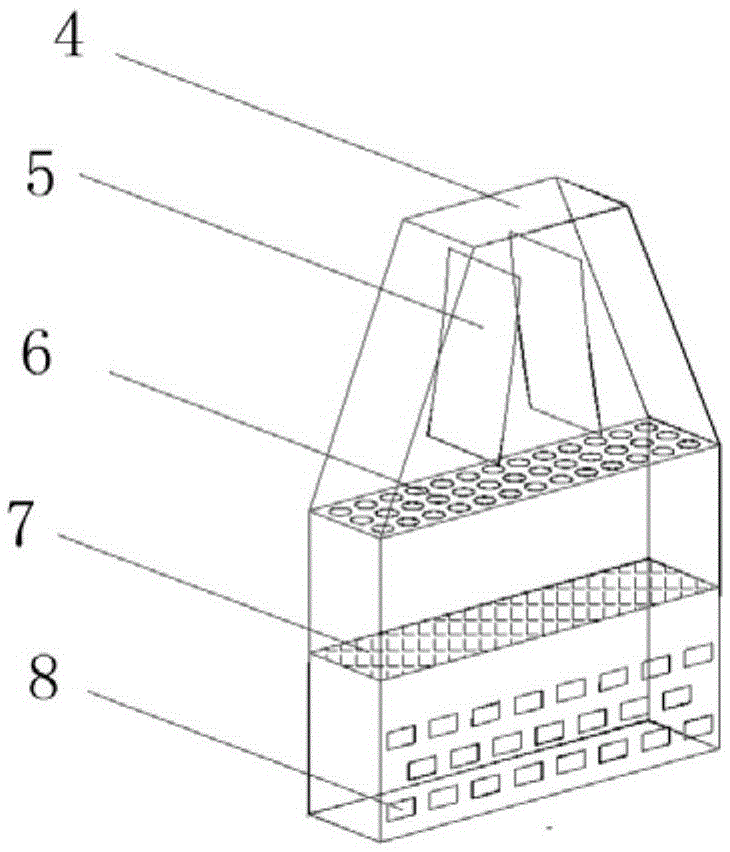

[0065] Each air distribution unit is composed of two parts: an air storage rectifier static pressure box and an air supply box. The body of the gas storage type rectifying plenum box is a polyhedral structure with an expansion section, which is surrounded by 6 panels: front, rear, upper left, lower left, upper right, and lowe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com