An ultra-wideband compact field feed based on dielectric loading

A technology of compact field feed and medium loading, which is applied in the direction of electrical components, transmission systems, waveguide speakers, etc., can solve problems such as inability to compress the field feed, and achieve the goal of improving test efficiency, reducing the size of the mouth and surface, and broadening the working frequency band Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

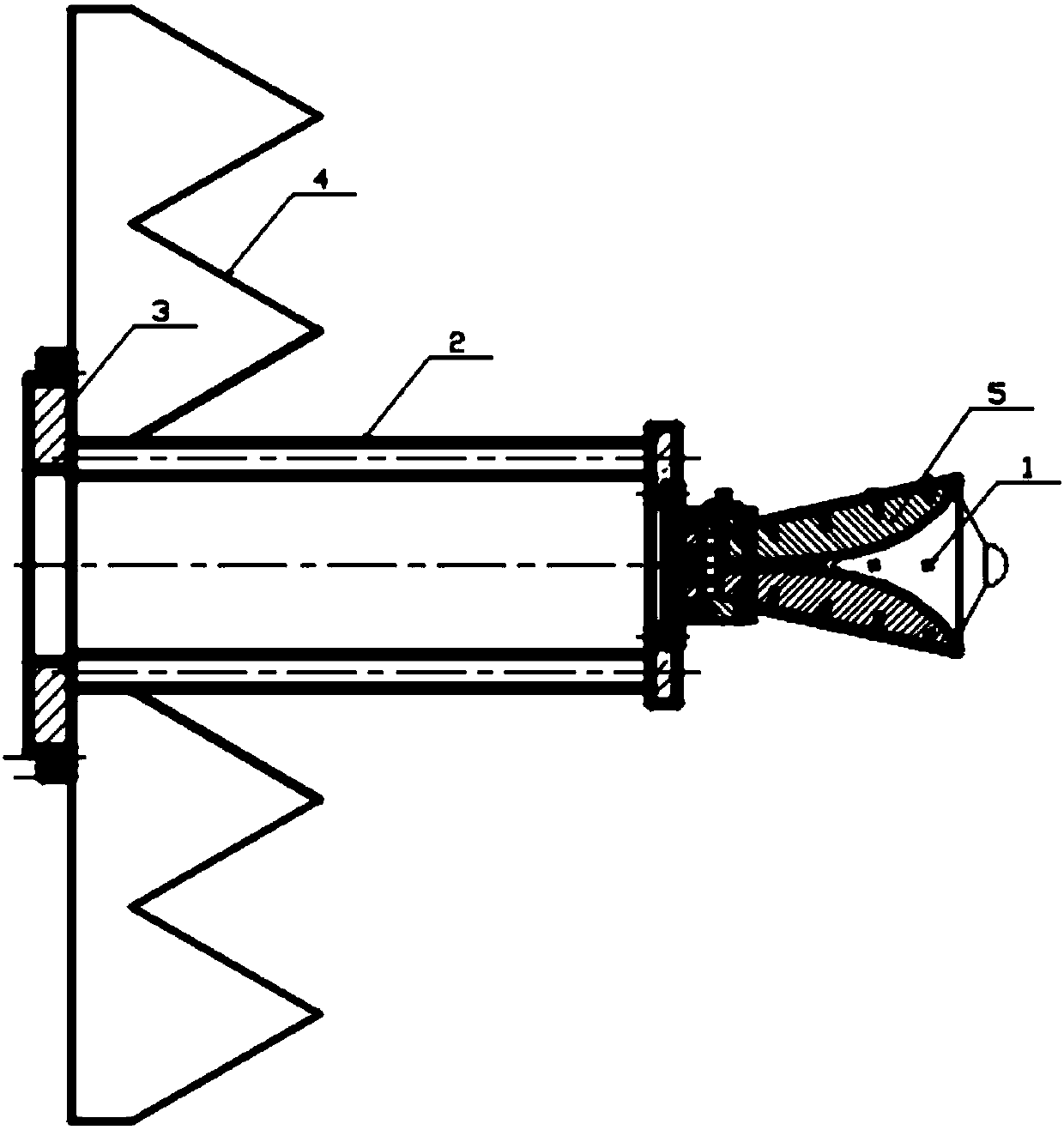

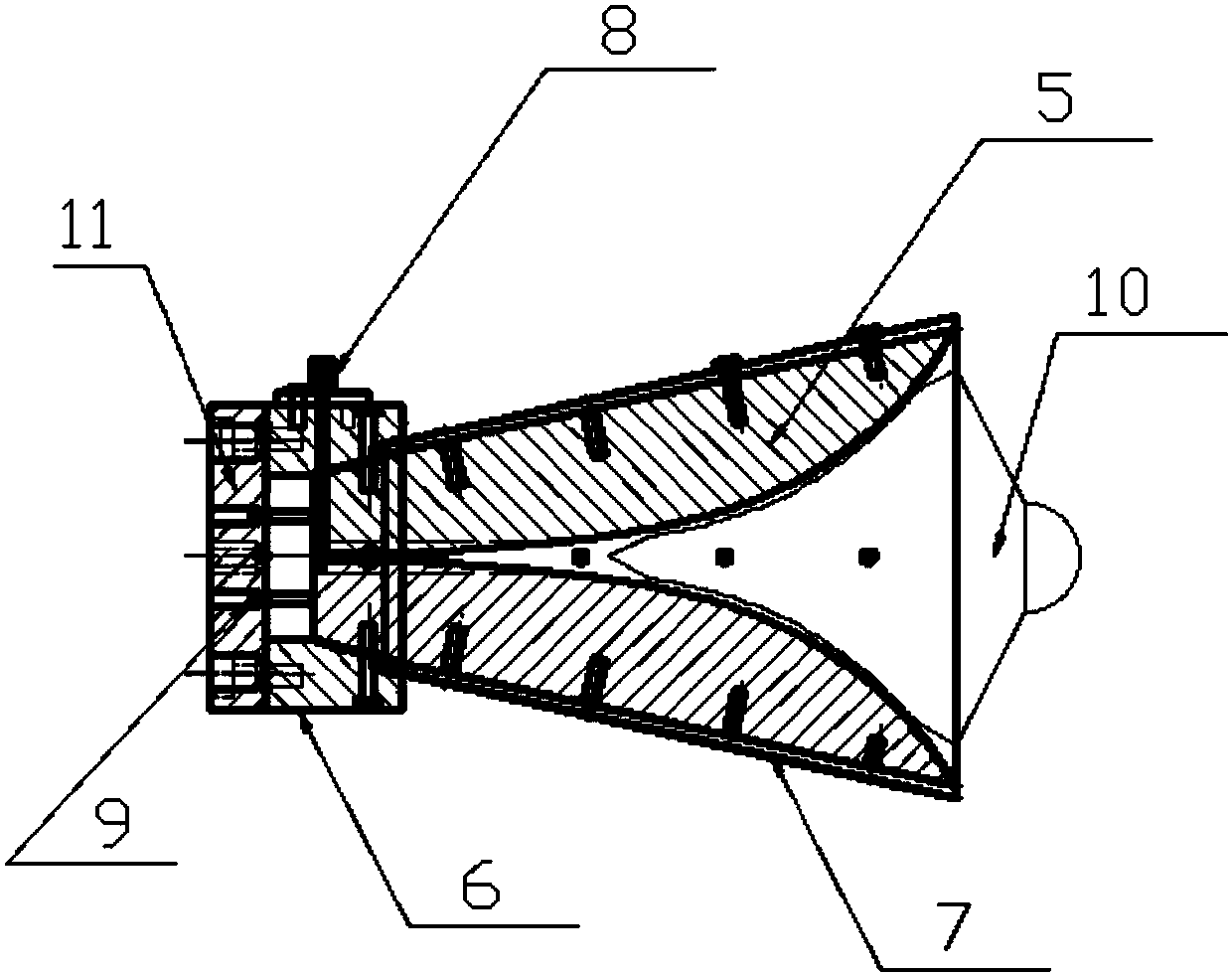

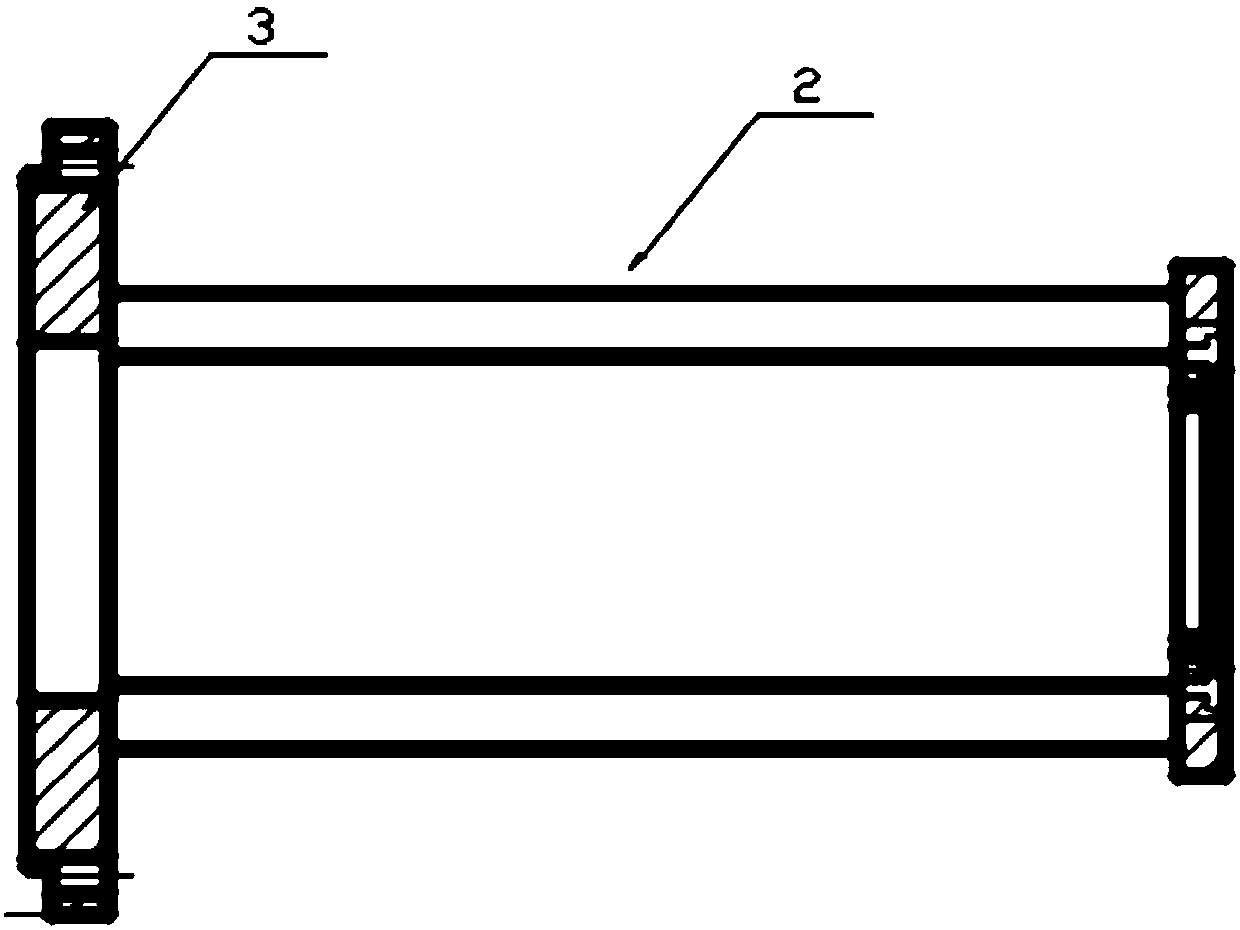

[0027] Design of the present invention is as follows: the present invention has good impedance bandwidth according to the four-ridge horn antenna, better pattern, through the mouth size of the ridge waveguide horn, axial length, ridge waveguide thickness, ridge spacing, ridge curve, ridge The design of key dimensions such as the waveguide size and the distance between the ridge and the back cavity enables the designed ridge waveguide horn to obtain the widest possible impedance bandwidth under two vertical polarizations, and then introduce PTFE loading. After adding polytetrafluoroethylene, the low-frequency cutoff frequency of the ridge waveguide horn is further reduced. By rationally designing the insertion position of polytetrafluoroethylene, the high-frequency radiation electric field can be concentrated on the dielectric structure without excessively deteriorating the impedance characteristics of the four-ridge horn. In this way, the splitting of the high-frequency pattern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com