A parallel induction heating power supply inverter feedback circuit and method

A technology of induction heating power supply and feedback circuit, applied in induction heating, induction current source, induction heating control and other directions, can solve the problems of circuit detuning, power factor reduction, large current generation and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

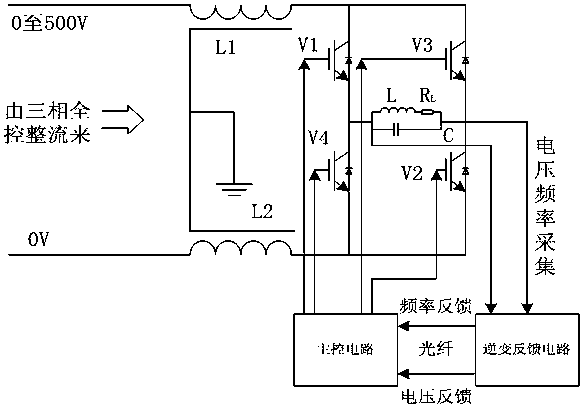

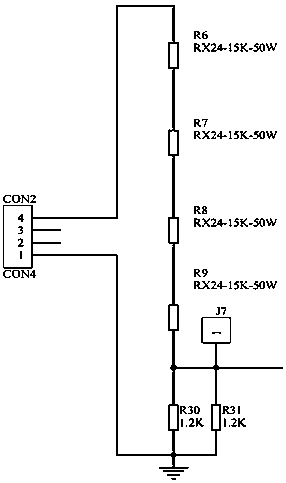

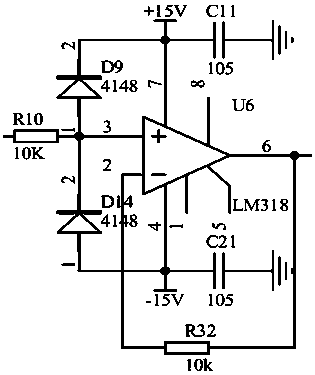

[0035] Such as figure 1 , 2 , 3, 4, 5, 6, 7, 8, a parallel induction heating power supply inverter feedback circuit, including: voltage divider circuit, voltage following limiter circuit, sinusoidal voltage amplification limiter shaping circuit, frequency feedback output circuit , a sinusoidal voltage rectification and filtering amplifier circuit, a voltage-frequency conversion circuit, and a voltage feedback output circuit, the voltage dividing circuit connected to the LC parallel resonant circuit is connected to the voltage following limiter circuit, and the output end of the voltage follower limiter circuit passes through the sinusoidal The voltage amplification limiting shaping circuit is connected to the frequency feedback output circuit, and the other output terminal of the voltage following limiting circuit is connected to the voltage feedback output circuit through the sinusoidal voltage rectification and filtering amplification circuit and the voltage-frequency conver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com