Low scattering silica glass, and method for thermally treating silica glass

一种热处理方法、石英玻璃的技术,应用在玻璃的成型、玻璃生产、玻璃制造设备等方向,能够解决石英玻璃透射率降低等问题,达到瑞利散射系数小、光传输损耗小、假想温度高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0108] Hereinafter, although an Example demonstrates this invention in detail, this invention is not limited to this.

[0109] Examples 1-3, Examples 6-8, and Example 14 are examples of the glass of the present invention, and Examples 4-5 and Examples 9-13 are comparative examples.

[0110] Examples 1-3, Example 6 and Example 14 are examples of the first method of the present invention. Examples 7 and 8 are examples of the second method of the present invention.

[0111] [Heat treatment of quartz glass]

example 1、2

[0113] Put dense quartz glass with an OH content of less than 50ppm into a pressure vessel, use argon as a pressurized medium, use a HIP device, and use a pump to heat while increasing the pressure of the gas. At 1800° C., the pressure (unit: MPa) shown in the column of pressure 1 in Tables 1 and 2 was maintained for 3.5 hours, and then the pump was stopped and quenched. The average cooling rate (unit: °C / min) from 1200°C to 900°C is described in the column of the cooling rate. During cooling, the pressure decreases due to thermal contraction of the gas.

[0114] In Tables 1 and 2, pressure 1 is the maximum pressure (unit: MPa) applied at the temperature shown in the column of temperature, and pressure 2 is the pressure (unit: MPa) when the temperature reaches 900° C. during the cooling process.

[0115] Holding time 1 shown in Tables 1 and 2 is the time for holding at the temperature shown in the column of temperature while applying the pressure shown in pressure 1, and hold...

example 3~5

[0117] Using the same quartz glass as in Examples 1 and 2, the pressure (unit: MPa) shown in the column of pressure 1 in Table 1 was applied at 1800° C. and held for 3.5 hours. The same as in Example 1 except that Carry out heat treatment.

[0118] (Example 6, 7)

[0119] Using the same quartz glass as in Example 1, after applying the pressure shown in the column of pressure 1 in Table 1 while maintaining at 1800°C for 2 hours, the temperature was lowered to 1600°C for Example 6, and the temperature was lowered for Example 7. As a result, the temperature decreased to 1200° C. and the pressure decreased, so the pressure was increased again using a pump, and the pressure shown in the column of applied pressure 1 was maintained for 0.5 hours. Afterwards, the pump was stopped and quenched.

PUM

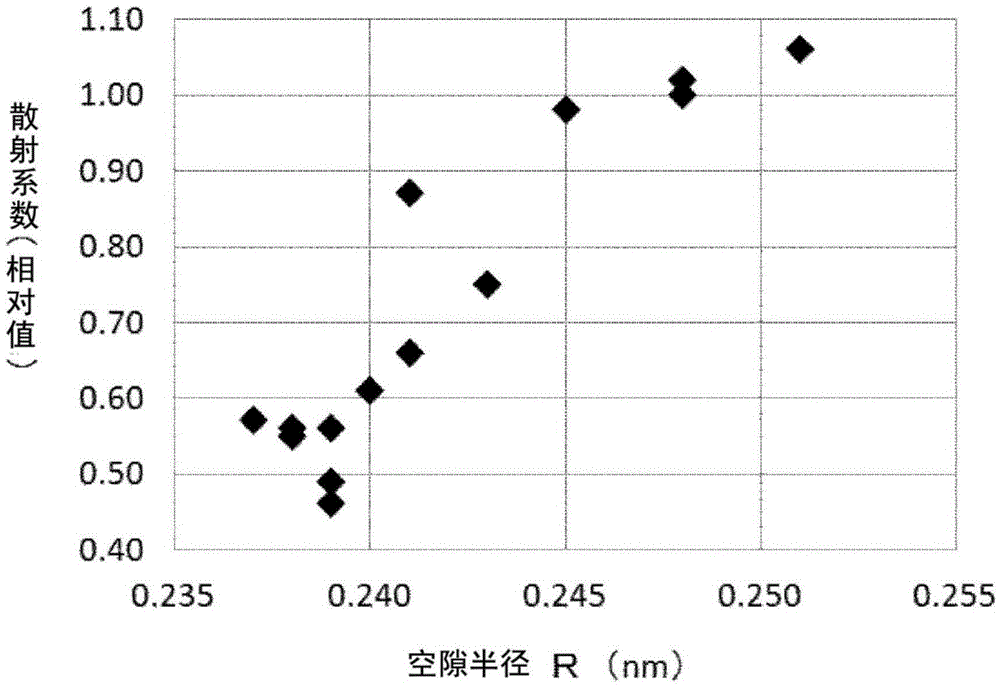

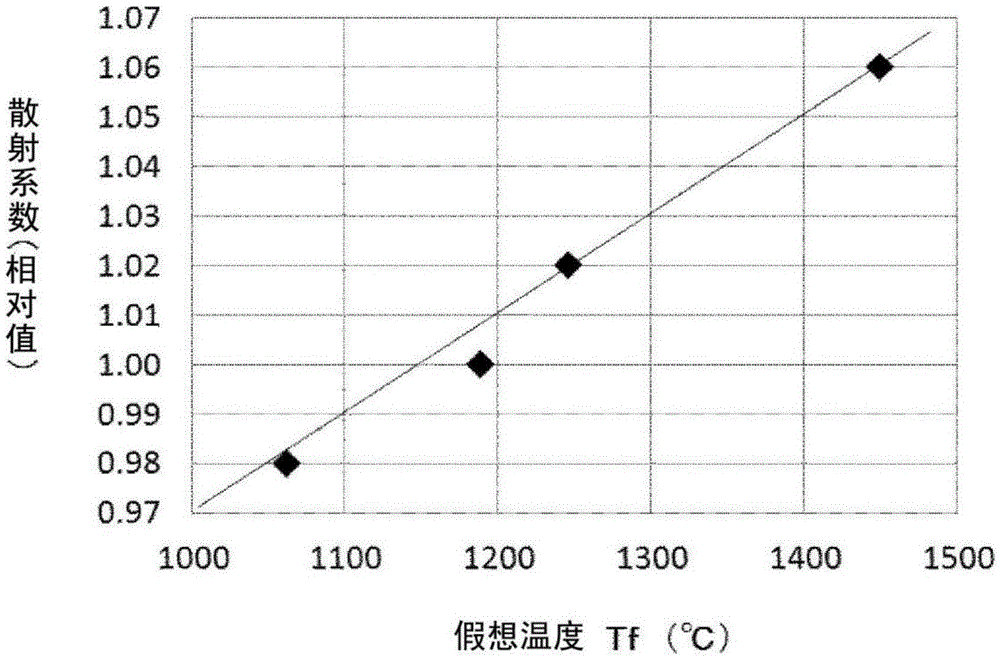

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| scattering coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com