Drip-irrigator assembly

A technology of drip irrigation head and components, which is applied in horticulture, botanical equipment and methods, cultivation, etc., and can solve the problem of high replacement cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical means adopted by the present invention to achieve the intended invention purpose are further described below in conjunction with the drawings and preferred embodiments of the present invention.

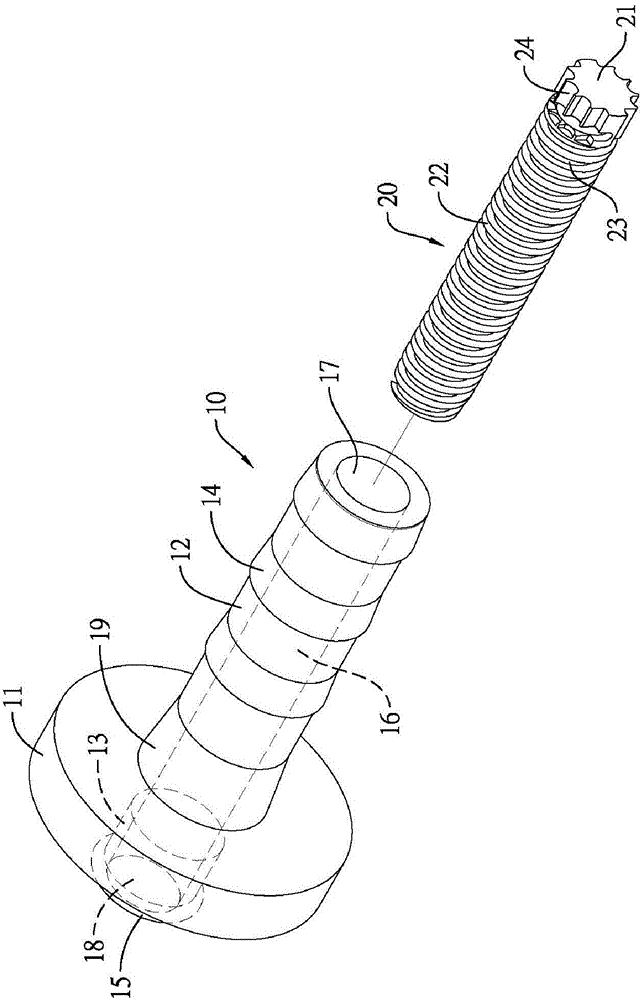

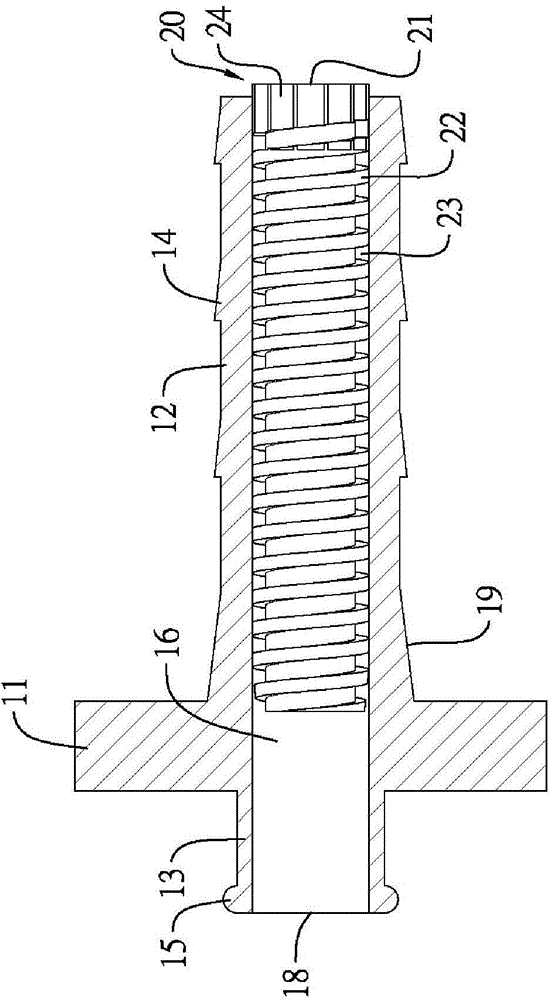

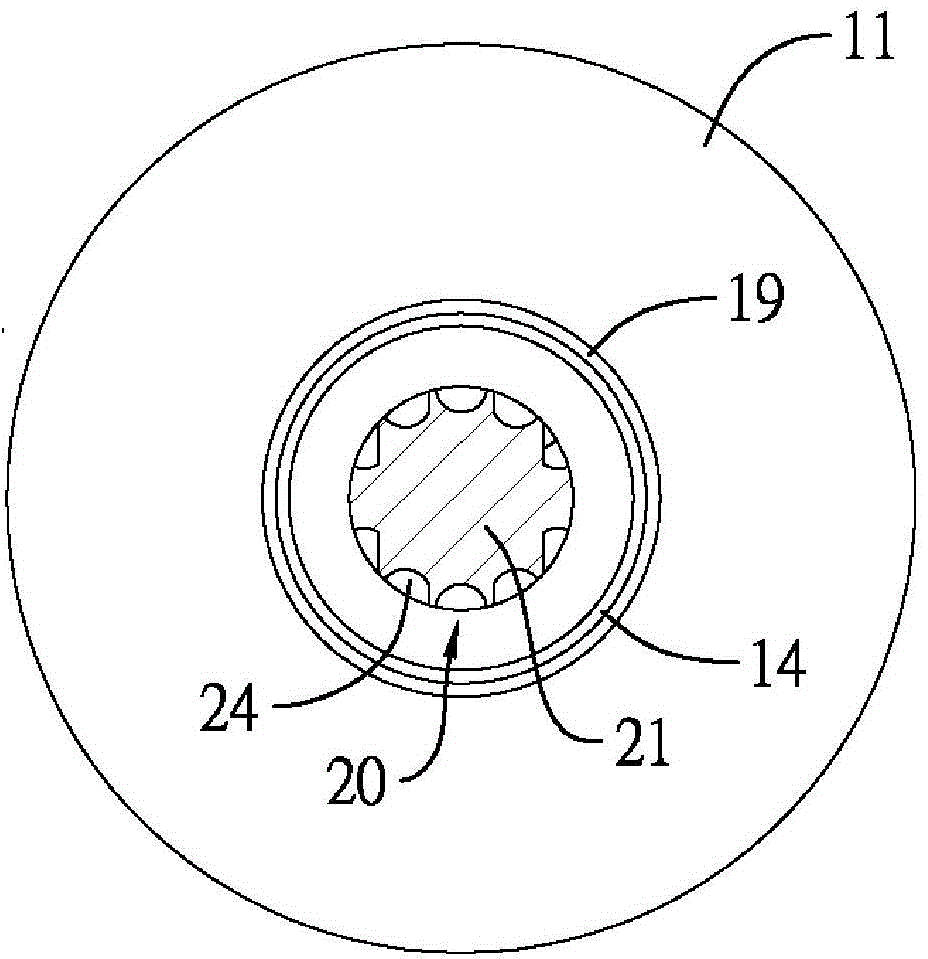

[0035] see Figure 1 to Figure 3 , is a preferred embodiment of the drip irrigation head assembly of the present invention, which includes an outer sleeve 10 and a slow flow member 20 .

[0036] The outer sleeve 10 includes a base 11, one side of the base 11 is provided with a laterally extending plug connector 12, and the other side of the base 11 is provided with a laterally extending sleeve connector 13, the plug connector 12 is provided with hooks 14 on the outer surface. In this preferred embodiment, the outer surface of the plug joint 12 is provided with a plurality of hooks 14 arranged at intervals. The outer surface of the sleeve joint 13 is provided with a protruding ring 15, and A channel 16 is formed in the outer sleeve 10, and an inlet 17 is formed at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com