A kind of freshwater fish composite fresh-keeping agent, preparation method and freshwater fish fresh-keeping method

A technology of composite fresh-keeping and fresh-keeping methods, which is applied in food preservation, meat/fish preservation with chemicals, food science, etc. It can solve problems such as adverse effects on sales and subsequent processing, quality cracking, texture cracking, etc., and improve storage stability The effect of slowing down texture cracking and being easy for industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

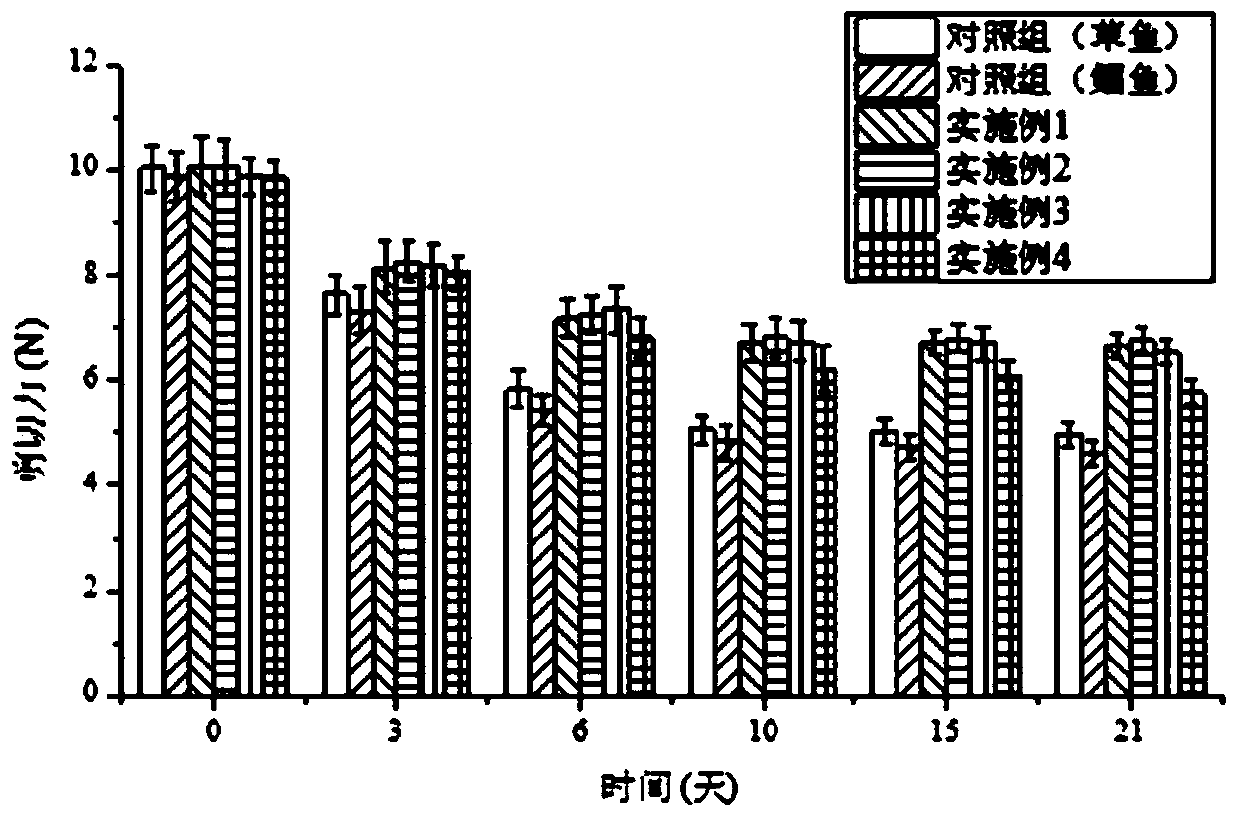

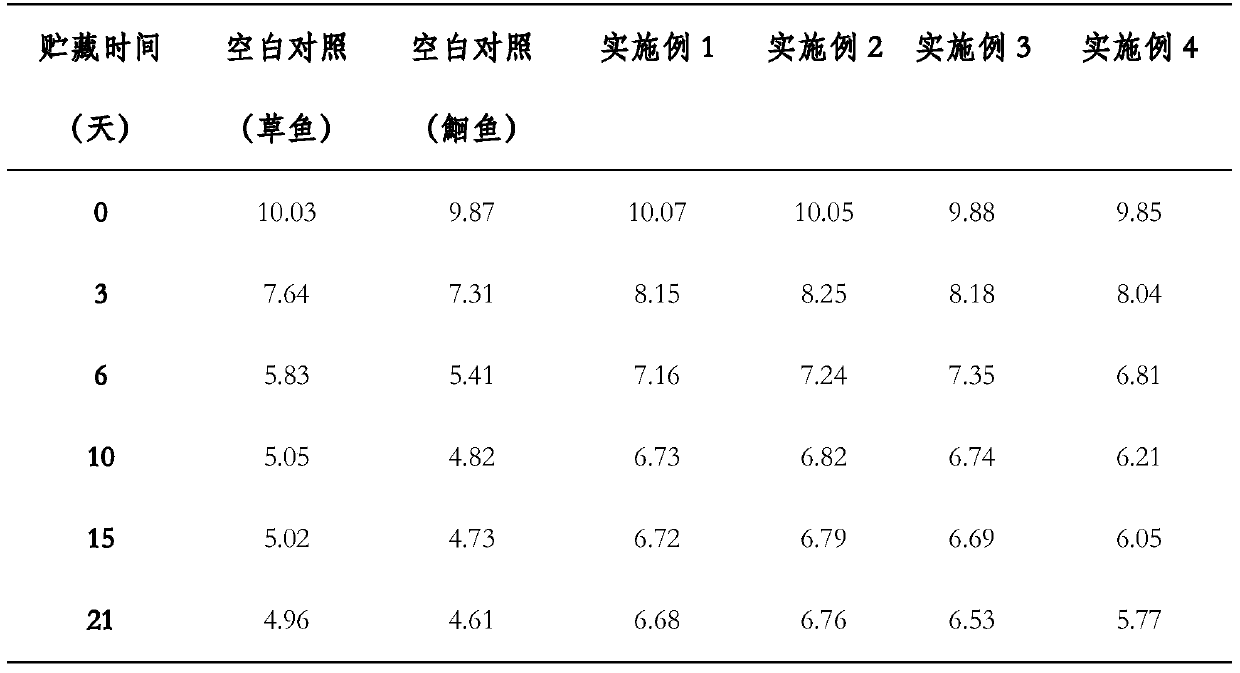

Examples

Embodiment 1

[0019] (1) Preparation of composite preservative:

[0020] Preparation of garlic extract: peel mature garlic, mash it, take garlic paste and put it in a container, add 100 times of water and soak at 25°C for 30 minutes, filter to remove residue, centrifuge, and supernatant for later use;

[0021] Preparation of green tea extract: take green tea and dry it in an oven at 60°C, crush it, add 100 times of water and soak it at 25°C for 60 minutes, and filter the supernatant as green tea extract for later use;

[0022] Preparation of perilla extract: take perilla, dry it in an oven at 60°C, crush it, add 100 times of water and soak it at 25°C for 60 minutes, and filter the supernatant as perilla extract for later use;

[0023] Three kinds of extracts are mixed, finally water makes the concentration of each component reach: garlic extract 3% (wherein the allicin content in the extract is 0.04%), green tea extract 4% (wherein the tea polyphenol content in the extract is 0.04%) 0.06%)...

Embodiment 2

[0029] (1) Preparation of composite preservative:

[0030] Preparation of garlic extract: peel mature garlic, mash it, take garlic paste and put it in a container, add 100 times of water and soak at 25°C for 30 minutes, filter to remove residue, centrifuge, and supernatant for later use;

[0031] Preparation of green tea extract: take green tea and dry it in an oven at 60°C, crush it, add 100 times of water and soak it at 25°C for 60 minutes, and filter the supernatant as green tea extract for later use;

[0032] Preparation of perilla extract: take perilla, dry it in an oven at 60°C, crush it, add 100 times of water and soak it at 25°C for 60 minutes, and filter the supernatant as perilla extract for later use;

[0033] Three kinds of extracts are mixed, finally water makes the concentration of each component reach: garlic extract 5% (wherein the allicin content in the extract is 0.06%), green tea extract 6% (wherein the tea polyphenol content in the extract is 0.06%) 0.08%)...

Embodiment 3

[0039] (1) Preparation of composite preservative:

[0040] Preparation of garlic extract: peel mature garlic, mash it, take garlic paste and put it in a container, add 100 times of water and soak at 25°C for 30 minutes, filter to remove residue, centrifuge, and supernatant for later use;

[0041] Preparation of green tea extract: take green tea and dry it in an oven at 60°C, crush it, add 100 times of water and soak it at 25°C for 60 minutes, and filter the supernatant as green tea extract for later use;

[0042] Preparation of perilla extract: take perilla, dry it in an oven at 60°C, crush it, add 100 times of water and soak it at 25°C for 60 minutes, and filter the supernatant as perilla extract for later use;

[0043]Three kinds of extracts are mixed, finally water makes the concentration of each component reach: garlic extract 4% (wherein the allicin content in the extract is 0.05%), green tea extract 5% (wherein the tea polyphenol content in the extract is 0.05%) 0.07%),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com