Metal tube processing fixture suitable for different tube diameters

A technology suitable for different and metal pipes, applied in the field of metal pipe processing, can solve problems such as low efficiency and low efficiency, and achieve the effects of high efficiency, simple operation, simple and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in combination with specific embodiments.

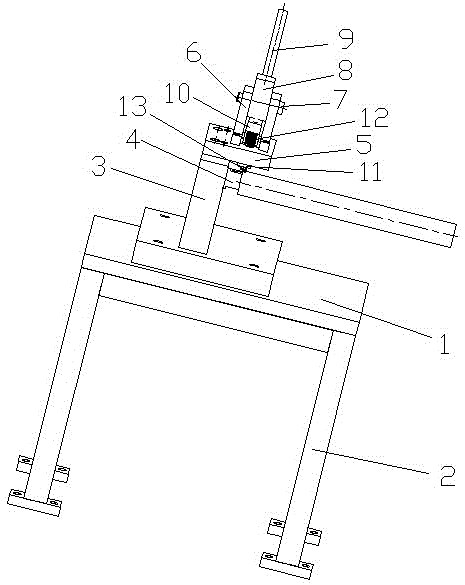

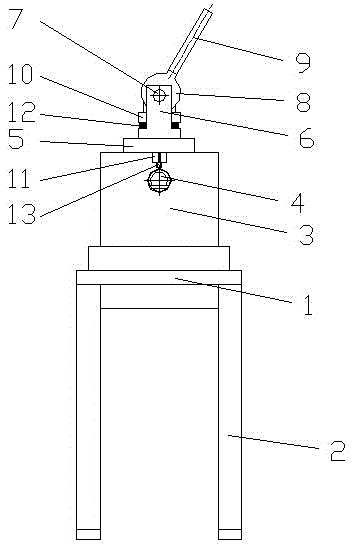

[0016] see figure 1 and figure 2 , the present invention can be adapted to metal pipe processing tooling with different pipe diameters, including a work platform 1 with supporting legs 2 at the four corners of the bottom surface of the work platform 1; The support plate 3 is provided with a horizontal sleeve stem 4 at the middle position along the height, and a horizontal connecting cross plate 5 is arranged at the upper end of the support plate 3 , and the connecting cross plate 5 and the casing stem 4 are located on the same side of the support plate 3 . Two vertically upward and parallel cam connecting blocks 6 are arranged on the connecting horizontal plate 5, and a cam 8 is provided through a horizontal rotating shaft 7 between the cam connecting blocks 6, and a handle 9 is provided on the peripheral surface of the cam 8, and the operating handle 9 can be Make cam 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com