Multi-exhaust pipe air blowing protection device for high-power laser welding

A technology of laser welding and air blowing protection, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as oxidation, and achieve the effects of good angle stability, beautiful appearance design, and easy measurement and recording

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

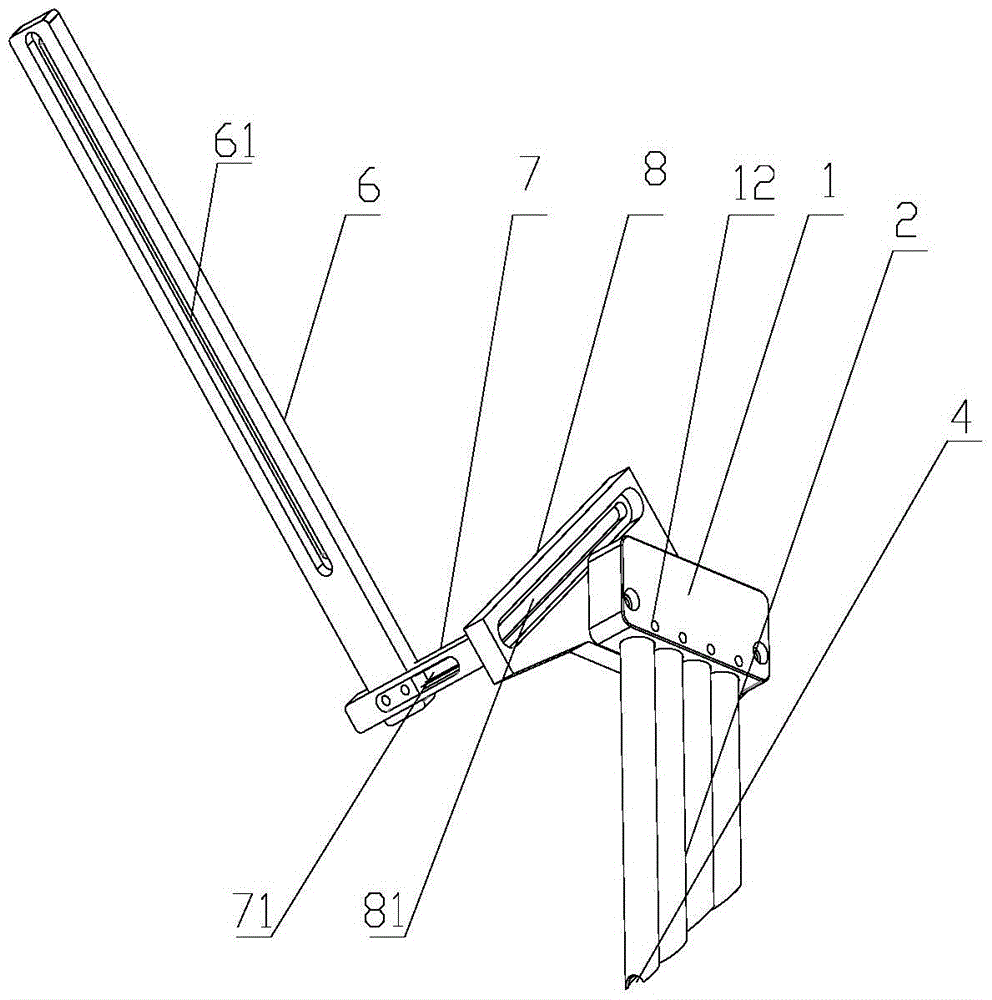

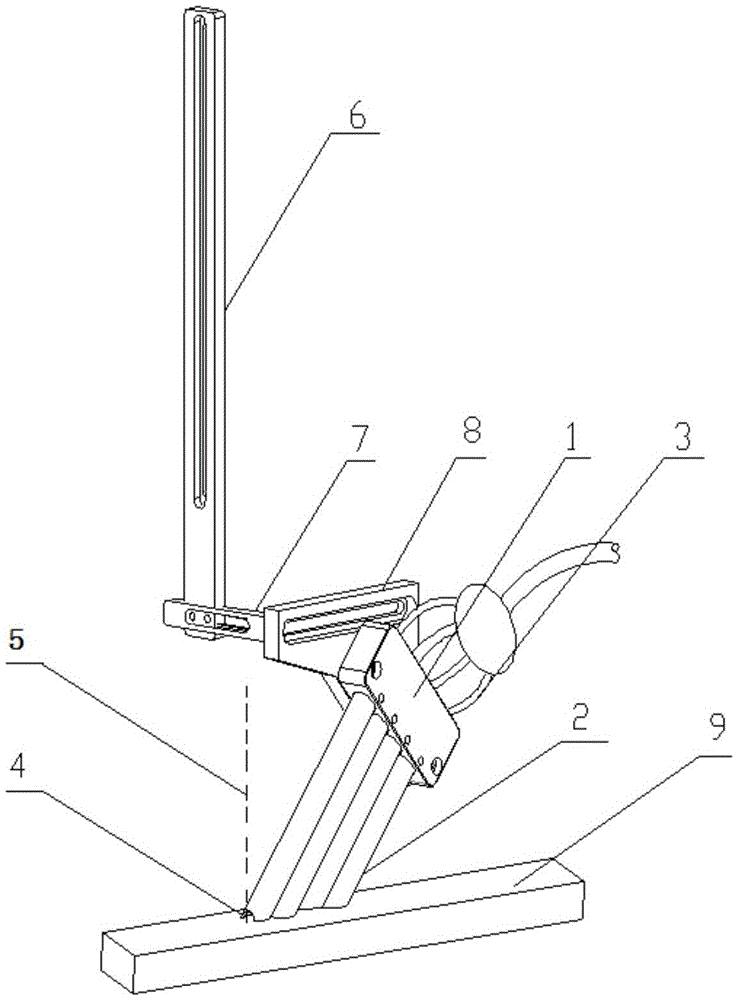

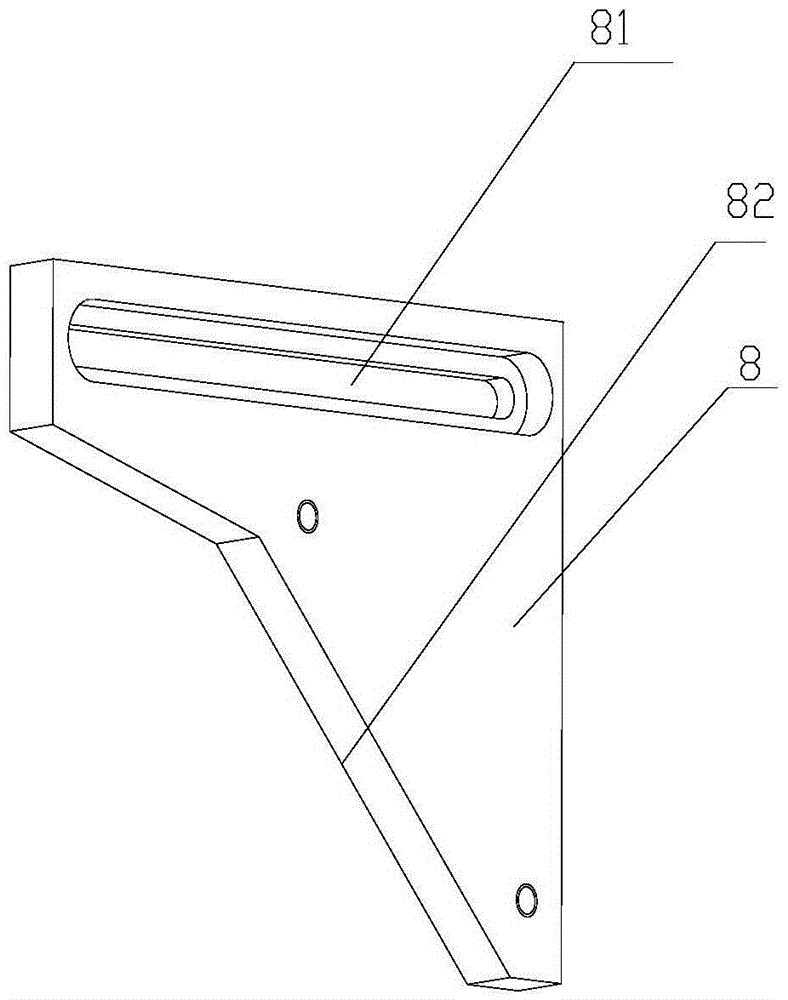

[0029] Such as Figure 1 to Figure 5 As shown, a multi-row tube blowing protection device for high-power laser welding includes a fixed seat 1 and a connecting device connected to the fixed seat 1, and the fixed seat 1 is provided with a plurality of welding rods along the welding surface to be processed. The exhaust pipes 2 arranged in the seam direction, the selection of the number of exhaust pipes 2 is diversified, and can be selected as 3, 4, 5, 6, 7, 8, 9, 10, but from the perspective of saving gas and improving efficiency From the point of view, the number of exhaust pipes 2 is preferably four, and the fixed seat 1 is also provided with an air supply pipe 3 connected to the exhaust pipe 2, and the axis of the exhaust pipe 2 and the vertical direction The included angle is preferably 15-75°, and an opening 4 for the laser to pass is provided at the nozzle of the first exhaust pipe 2 in the incident direction of the laser. Of course, the angle between the axis of the exha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com