Double-pressure-tank shot generation system in shot blasting device

A dual-pressure tank and generating system technology, applied in metal processing equipment, abrasives, manufacturing tools, etc., can solve the problem of unstable pellet flow, achieve the effect of ensuring pellet flow and delaying the inflation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

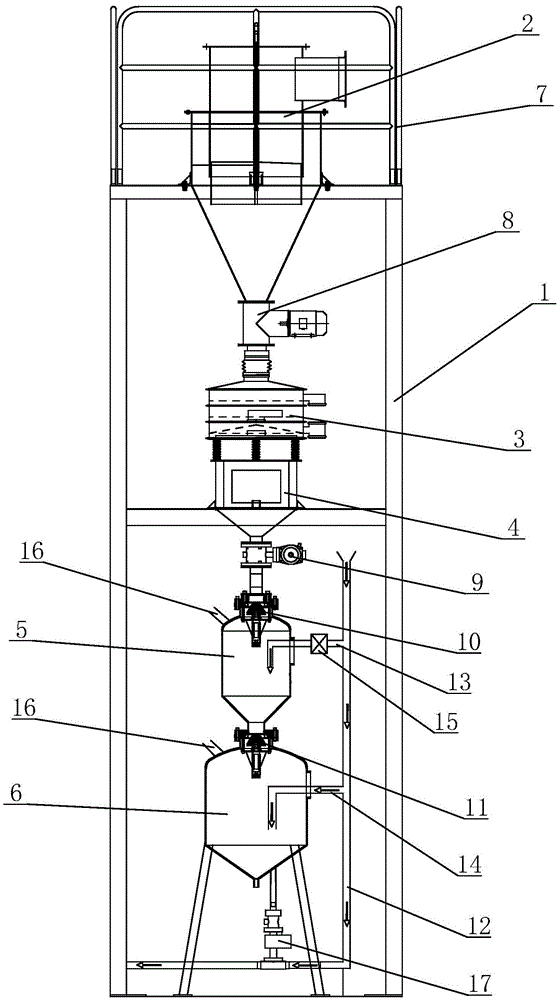

[0015] see figure 1 as shown, figure 1 It is a schematic structural view of the double-pressure tank shot generation system in the shot peening equipment provided in Embodiment 1 of the present invention.

[0016] A double-pressure tank shot generation system in shot blasting equipment includes a frame 1, on which a cyclone separator 2, a vibrating screen 3, a storage hopper 4, and an upper shot blasting tank are sequentially arranged from top to bottom and connected to each other 5 and the lower shot blast tank 6, the top of the frame 1 is provided with a guardrail 7 on the periphery of the cyclone separator 2. A blower fan 8 is set between the cyclone separator 2 and the vibrating screen 3, a feed valve 9 is set between the storage hopper 4 and the upper shot blast tank 4, and the upper part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com