Follow-up saw blade guard

A saw blade cover and follow-up technology, which is applied to metal processing machinery parts, maintenance and safety accessories, work accessories, etc., can solve the problems of high cost, high material consumption and heavy shape of the saw blade cover, and improve the device Long service life, improved operating comfort, and low production and processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

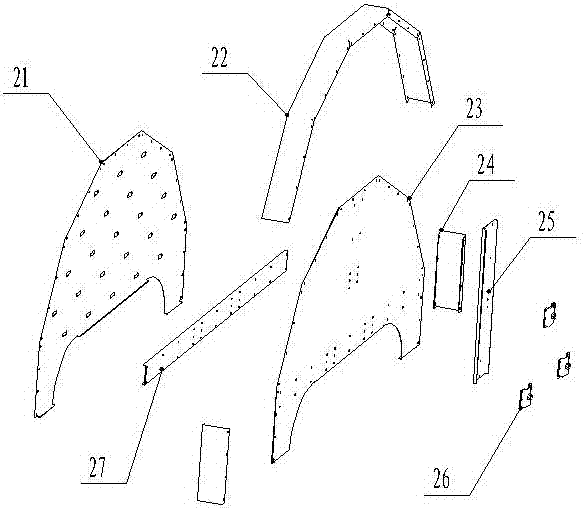

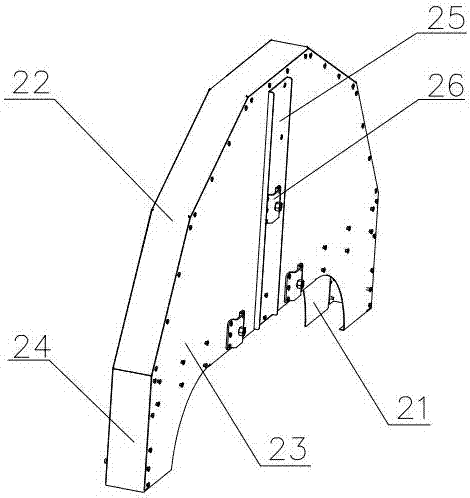

[0030] Such as figure 1 and figure 2 As shown, a follow-up saw blade cover includes a rear cover 21, a front cover 23 opposite to the rear cover 21 and separated by a cavity for covering the saw blade, and connected to the top of the rear cover 21 and the front cover 23. The top plate 22, the side plate 24 connected to the side ends of the rear cover 21 and the front cover 23 and connected to the bottom of the top plate 22, the reinforcement rib II 25 vertically fixed on the outside of the front cover 23, and the reinforcement rib II 25 horizontally fixed on the inside of the front cover 23 I27. Three supporting and fixing plates 26 arranged on the front cover 23.

[0031] Rear cover 21 and front cover 23 as figure 1 and figure 2 As shown, including the main structure and the connecting part, the main structures of the rear cover 21 and the front cover 23 are all shapes after a part is cut by a circular horizontal knife, but the upper edges of the two are not smooth arc l...

Embodiment 2

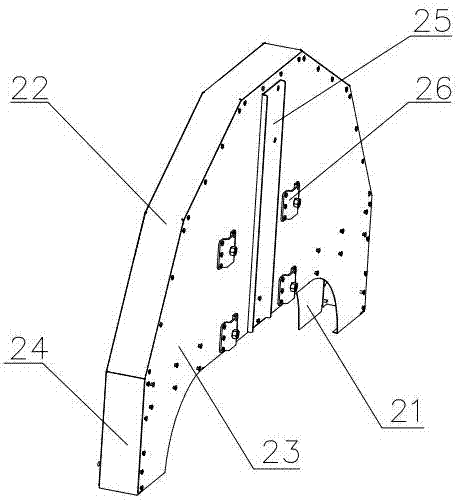

[0036] The difference between this embodiment and embodiment 1 is: see image 3 , there are four supporting and fixing plates 26, which are evenly arranged at the lower part of the front cover 23, and of course can also be evenly arranged at the middle part of the front cover 23; to the settings.

Embodiment 3

[0038] The difference between this embodiment and embodiment 1 is: see Figure 4 and Figure 5 , is also provided with a folding water retaining mechanism, and the folding water retaining mechanism includes two L-shaped fixed plates 4 fixed on the bottom of the rear cover 21 and the front cover 23 by riveting the head end respectively, and two L-shaped fixed plates 4. The two-stage water retaining piece made of channel steel is movably connected at the tail end. There are three riveting holes on the fixed plate 4, and the three riveting holes are arranged in a triangle; The tail end of the fixed plate 4, the head end of the second level water retaining sheet is movably connected to the tail end of the first stage water retaining sheet, the first stage water retaining sheet 1 is slightly wider than the board part of the second stage water retaining sheet 2, install Put the head end of the second-stage water retainer 2 into the tail end of the first-stage water retainer 1, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com