Automobile air conditioning vent panel and preparation method thereof

A technology for automotive air conditioners and air outlets, applied in coatings and other directions, can solve problems such as poor sound insulation of air outlet panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0013] The invention provides a method for preparing an air outlet panel of an automobile air conditioner, wherein the preparation method comprises: mixing polyethylene, polypropylene, azodicarbonamide, phenolic resin, an emulsifier and a plasticizer, heating and molding to obtain Panel body M; mix wood fiber, polyester fiber and isocyanate to form colloid N; apply colloid N on the surface of panel body M, and obtain an air outlet panel after baking, wherein, relative to 100 parts by weight of polyethylene , the consumption of polypropylene is 50-100 parts by weight, the consumption of azodicarbonamide is 20-45 parts by weight, the consumption of phenolic resin is 30-45 parts by weight, the consumption of emulsifier is 2-10 parts by weight, plasticizing The consumption of the agent is 2-10 parts by weight, the consumption of the wood fiber is 80-120 parts by weight, the consumption of the polyester fiber is 80-100 parts by weight, and the consumption of the isocyanate is 20-55 ...

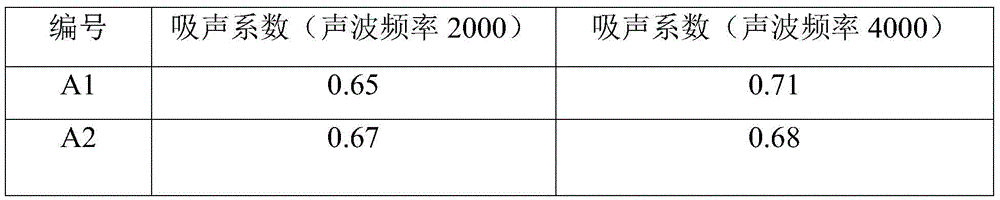

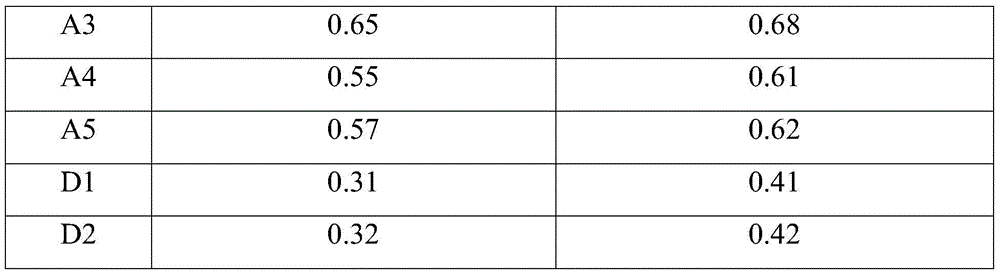

Embodiment 1

[0021] After mixing 100g of polyethylene, 65g of polypropylene, 30g of azodicarbonamide, 35g of phenolic resin, 4g of octylphenol polyoxyethylene ether and 4g of dioctyl phthalate, heating and molding to obtain the panel body M; 90g of wood fiber, 85g of polyester fiber and 35g of isocyanate are mixed to form colloid N; Colloid N is coated on the surface of panel body M, and after baking, air outlet panel A1 is obtained, wherein the weight average molecular weight of polyethylene is 12000, poly The weight average molecular weight of propylene is 8000, the baking temperature is 50° C., and the baking time is 10 minutes.

Embodiment 2

[0023] After mixing 100g of polyethylene, 85g of polypropylene, 35g of azodicarbonamide, 40g of phenolic resin, 8g of benzyldimethylphenol polyoxyethylene ether and 8g of dioctyl phthalate, heating and molding to obtain a panel blank Body M; 110g wood fiber, 95g polyester fiber and 45g isocyanate are mixed to form colloid N; colloid N is coated on the surface of panel body M, and after baking, air outlet panel A2 is obtained, wherein the weight average molecular weight of polyethylene The weight average molecular weight of polypropylene is 12000, the baking temperature is 75°C, and the baking time is 25min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com