Insulation box filling glue and preparation method thereof

A technology of filling glue and A component for insulation box, applied in the field of epoxy filling glue, can solve the problems of worsening unit accident, low production efficiency, overflow of filling glue, etc., and achieve the effect of improving production efficiency, saving cost and good compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

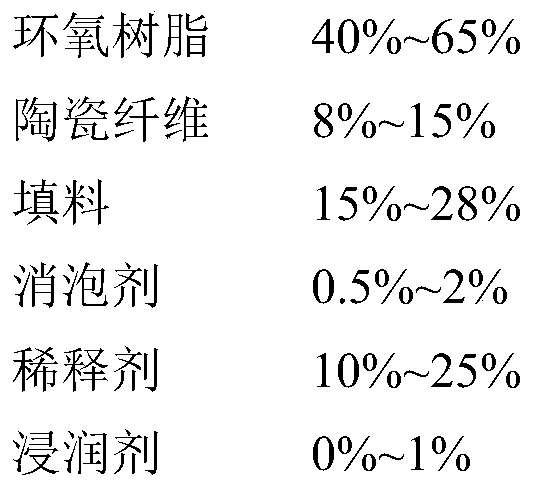

[0025] Preparation of component A: Add epoxy resin, defoamer and diluent to the container in order by weight percentage, stir and mix evenly; then, add 8% to 15% of ceramic fiber while stirring, and mix evenly; then, Add 15%~28% of filler and 0%~1% of wetting agent while stirring and mix evenly; after that, vacuumize for 30 minutes to 60 minutes while stirring, control the vacuum degree not higher than -0.1MPa, and get Group A after discharging share;

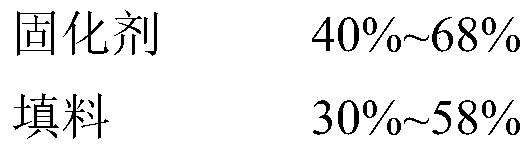

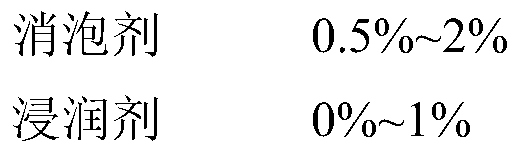

[0026] Preparation of component B: Add curing agent and defoamer to the container by weight percentage, stir and mix evenly; then, add filler and sizing agent while stirring and mix evenly; after that, vacuumize while stirring for 30 minutes to 60 minutes Minutes, control the vacuum degree not to be higher than -0.1MPa, and get component B after discharging.

Embodiment

[0028] According to the amount of each substance shown in Table 1 (by weight ratio), 4 kinds of insulating box filling glues were prepared.

[0029] Table 1

[0030]

[0031]

[0032] According to the mass ratio of component A: component B = 2.5:1, mix evenly, perform performance test after curing, and the results are shown in Table 2.

[0033] Table 2

[0034] indicators

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| dielectric strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com