Pipeline composite abrasion resisting functional layer, abrasion-resisting pipeline inner wall and manufacturing method of pipeline composite abrasion resisting functional layer and abrasion-resisting pipeline inner wall

A production method and a technology of functional layers, applied in pipeline damage/abrasion prevention, pipeline protection, pipes/pipe joints/fittings, etc., can solve problems such as cavitation and pipeline safety threats, achieve strong wear resistance, and improve service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

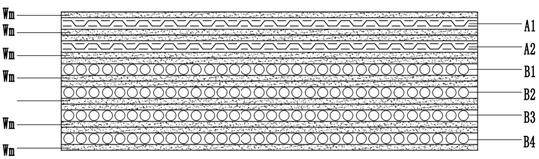

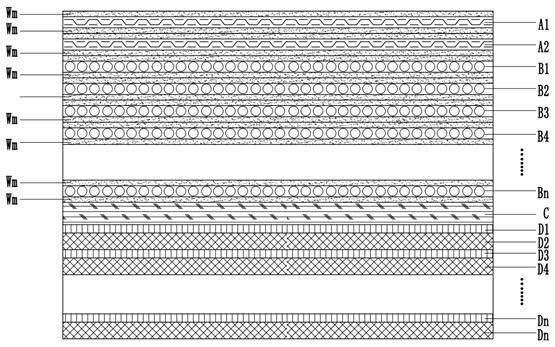

[0050] This embodiment discloses a composite wear-resistant functional layer structure for pipelines. With the inner wall surface of the pipeline as the inner side, two layers of multi-directional woven fiber cloth wear-resistant reinforcement layers and four layers of axially woven fiber cloth wear-resistant layers are sequentially compounded outward. enhancement layer. The two-layer multi-directional woven fiber cloth wear-resistant reinforced layer includes a first multi-directional woven fiber cloth wear-resistant reinforced layer A1 and a second multi-directional woven fiber cloth wear-resistant reinforced layer A2. The 4-layer axially woven fiber cloth wear-resistant reinforcing layer includes a first uniaxially woven fiber cloth wear-resistant reinforcing layer B1, a first biaxially woven fiber cloth wear-resistant reinforcing layer B2, a second uniaxially woven fiber cloth Cloth wear-resistant reinforcement layer B3 and the second biaxially woven fiber cloth wear-resis...

Embodiment 2

[0053] A method for manufacturing a composite wear-resistant functional layer for a pipeline includes the following steps:

[0054] Step 1: Preparation of resin mixed with hydrophobic fumed silicon

[0055] Add hydrophobic fumed silicon into the bisphenol A vinyl resin, the amount of the hydrophobic fumed silicon added is 1.4% of the mass fraction of the bisphenol A vinyl resin, and stir well and evenly. The particle size of the hydrophobic fumed silica is 12-16 nm.

[0056] Step 2: Preparation of resin mixed with wear-resistant silicon carbide micropowder

[0057] Add silicon carbide micropowder to the bisphenol A vinyl resin mixed with hydrophobic silicon carbide, the addition amount of the silicon carbide micropowder is 21% of the mass fraction of bisphenol A vinyl resin, after fully stirring, then add Accelerator, stir evenly, add curing agent, after stirring evenly, obtain pre-crosslinked solidified mixed wear-resistant micropowder resin; the Mohs hardness of the silico...

Embodiment 3

[0065] A method for manufacturing a composite wear-resistant functional layer for a pipeline includes the following steps:

[0066] Step 1: Preparation of resin mixed with hydrophobic fumed silicon

[0067] Add hydrophobic fumed silicon to the bisphenol A vinyl resin, the amount of the hydrophobic fumed silicon is 1.6% of the mass fraction of the bisphenol A vinyl resin, and stir well and evenly. The particle size of the hydrophobic fumed silica is 12-16 nm.

[0068] Step 2: Preparation of resin mixed with wear-resistant silicon carbide micropowder

[0069] Add silicon carbide micropowder to the bisphenol A vinyl resin mixed with hydrophobic silicon carbide, the addition amount of the silicon carbide micropowder is 23% of the mass fraction of the bisphenol A vinyl resin, after fully stirring, then sequentially add Accelerator, stir evenly, add curing agent, after stirring evenly, obtain pre-crosslinked cured mixed wear-resistant micro-powder resin;

[0070] The Mohs hardnes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com