Ceramic water quality adaptability peptizer containing polyamine epoxy adduct polymethylene phosphonate

A technology of methylene phosphonate and adduct, which is applied in the field of fine chemical industry of ceramic additives, can solve the problems of low water reduction rate, poor degumming adaptability, unstable adaptability, etc., and achieves small fluidity loss and increased fluidity. , Significant water reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

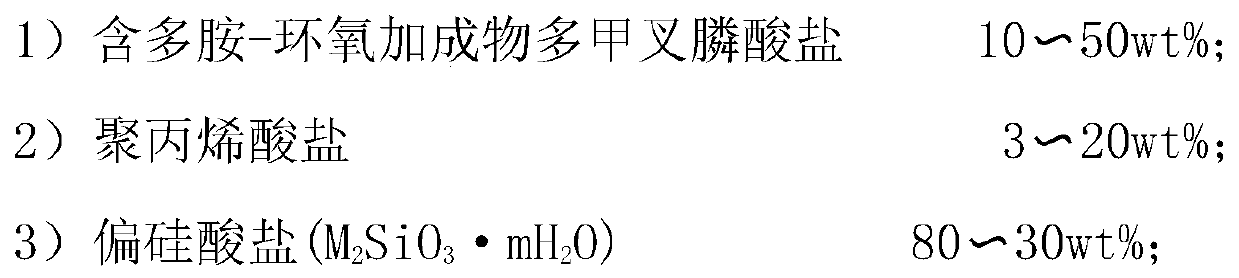

[0030] The polyamethylene phosphonate containing polyamine-epoxy adduct is sodium salt or potassium salt, which is prepared by the following method:

[0031] a) at Slowly add 1 mole part of polyalkylene glycol diglycidyl ether to 2 mole parts of polyamine with stirring, maintaining stirring reaction hours, then warmed to stirring reaction Hour, cooling, obtain polyamine-epoxy adduct;

[0032] b) then add deionized water that is more than 1 times the total weight of polyamine and polyalkylene diglycidyl ether and dropwise 37.5% hydrochloric acid of the total weight of polyamine and polyalkylene diglycidyl ether, and stir to make it dissolve, add polyamine-epoxy adduct active hydrogen (N-H) molar part Phosphorous acid and equal weight of deionized water to dissolve, the temperature dropped to When adding formaldehyde solution dropwise, the molar fraction of formaldehyde is that of phosphorous acid After the dropwise addition was completed, the temperature was r...

Embodiment 1

[0040] (1) in Slowly add 1 mole part of polyethylene glycol diglycidyl ether (average molecular weight is 380) to 2 mole parts of diethylenetriamine (molecular weight is 103) under stirring, keep in a cold water bath Stir the reaction for 6 hours, then raise the temperature to 55° C., stir the reaction for 6 hours, and cool to obtain 586 grams of polyamine-epoxy adduct;

[0041] (2) Then add 600 grams of deionized water, add dropwise 650 grams of 37.5wt% hydrochloric acid, and stir to dissolve it, add 656 grams of phosphorous acid (8 molar parts, molecular weight 82) and 656 grams of deionized water to dissolve , the temperature drops to 37wt% formaldehyde solution was added dropwise to a total of 680 grams, and after the dropwise addition, the temperature was raised to Reacted for 5 hours, then bubbled a large amount of air to remove most of the acidic HCl gas, neutralized to pH with 40wt% sodium hydroxide aqueous solution after cooling Obtain the aqueous solution con...

Embodiment 2

[0045] (1) Get 42.25 grams of 35.5wt% AEPS1, 5 grams of sodium polyacrylate (average molecular weight 9000), 186.23 sodium metasilicate nonahydrate (containing 80 grams of sodium metasilicate) and 41.52 grams of deionized water, mix and dissolve, and prepare 275 grams of 36.36wt% debonding agent JJJ2;

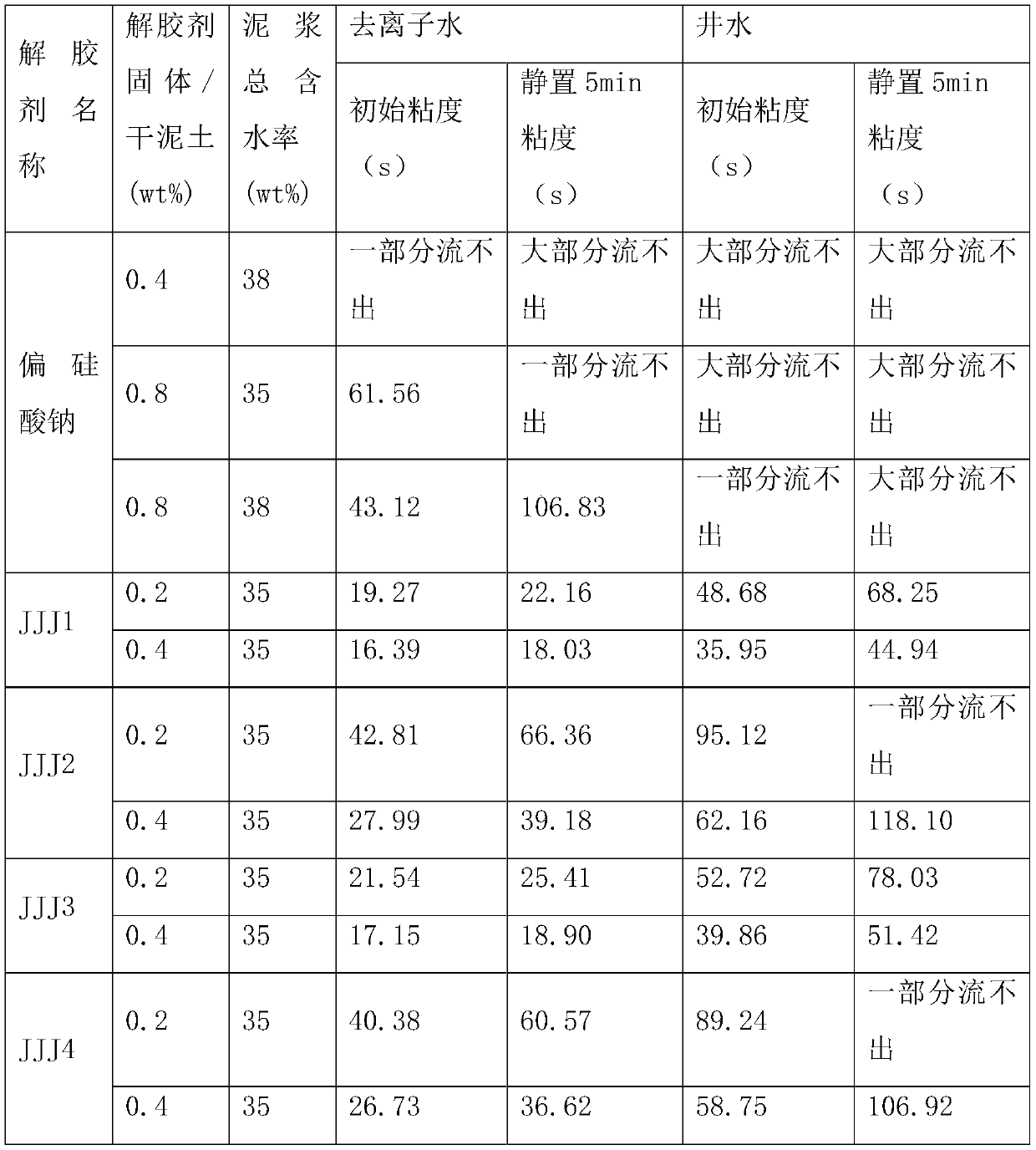

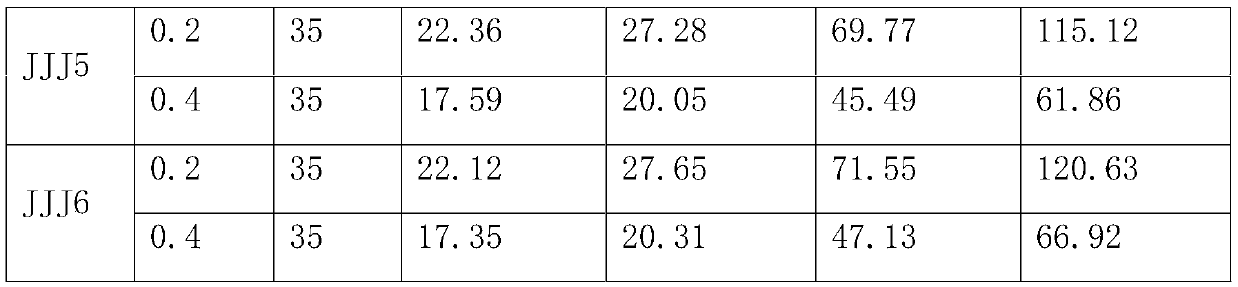

[0046] (2) get its certain consumption then, respectively with two kinds of water quality (deionized water, well water (Ca, Mg, Al total 900ppm)) that contain different high valence calcium, magnesium, aluminum compound content with the water content of 35wt% and ceramics Clay (Sibelco GF-M250) was mixed and ground for 10 minutes, and its debonding effect on ceramic slurry was observed at room temperature 25°C, and the experimental results are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com