Composite polycarboxylate superplasticizer mother liquor and preparation method and application thereof

A composite polycarboxylic acid and water reducing agent technology, which is applied in the field of polycarboxylic acid water reducing agent, can solve the problems of double bond breakage of macromonomers, cumbersome operation procedures, and reduced conversion of raw materials, etc., and achieves good slow release and collapse protection. The effect of single performance, single solution performance, and improved water reduction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

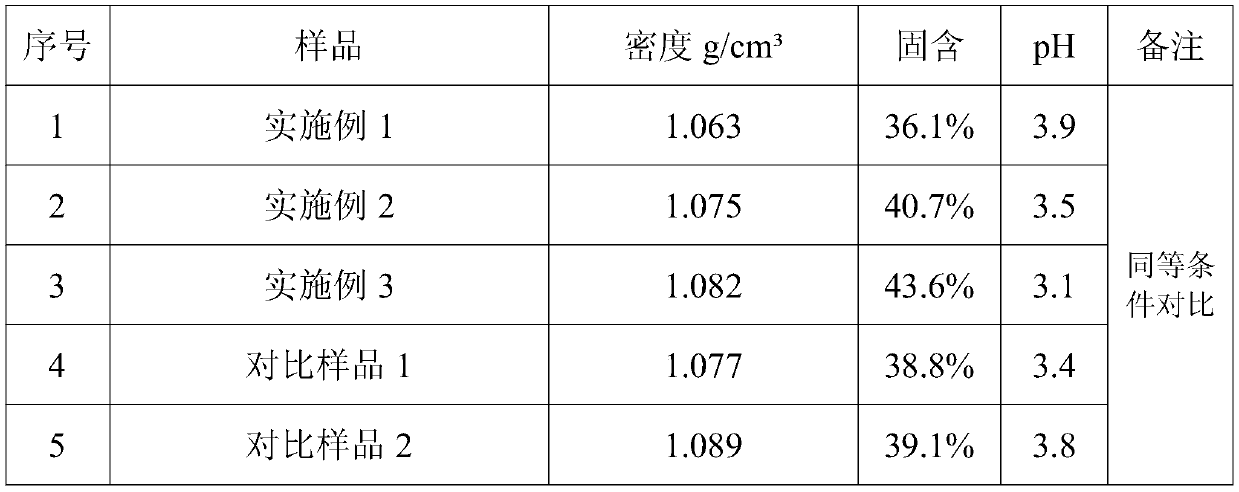

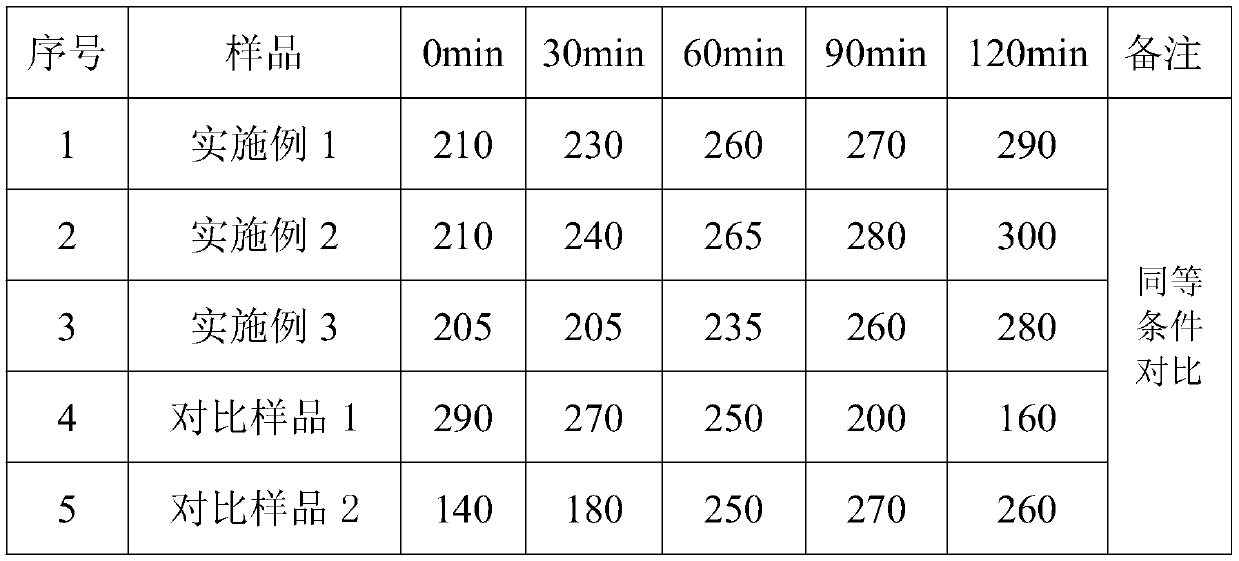

Examples

preparation example Construction

[0027] The preparation method of composite polycarboxylate superplasticizer mother liquor specifically comprises the following steps:

[0028] Dissolving component a, hydroxyethyl acrylate and hydroxypropyl acrylate in water to prepare solution A for use; wherein component a is acrylic acid and / or methacrylic acid;

[0029] Dissolve component b and component c in water to prepare solution B for use; wherein, component b is one or more of mercaptopropionic acid, thioglycolic acid or mercaptoethanol, and component c is vitamin C and / or sodium formaldehyde sulfoxylate;

[0030] After adding water to the reaction vessel, put in the macromonomer, and control the temperature of the reaction vessel within the range of 25-31°C, add the oxidant after the macromonomer is completely dissolved, and mix evenly;

[0031] Add the solution A and solution B dropwise into the reaction container respectively, and the dropwise addition time is 2.0-3.5h. After the dropwise addition is completed, ...

Embodiment 1

[0039] 18g of acrylic acid, 20g of hydroxyethyl acrylate and 15g of hydroxypropyl acrylate were dissolved in 30g of water to prepare solution A; 1.5g of mercaptopropionic acid and 0.6g of vitamin C were dissolved in 30g of water to prepare Solution B. Stir solution A and solution B evenly and pour them into the dropping tank.

[0040] Put 280g of water into the reactor and turn on the stirring mode, then put in 310g of methyl butenyl polyoxyethylene ether, heat the reactor in a water bath, and control the temperature of the reactor within the range of 25-31°C; After the butenyl polyoxyethylene ether is completely dissolved, add 4 g of ammonium persulfate and stir for 3 minutes.

[0041] Add solution A and solution B dropwise to the reactor at the same time, the duration of solution A is 2.0h, and the duration of solution B is 3.5h; after the addition is completed, continue to stir and keep warm for 0.5h, and then add After diluting with 290.9 g of the remaining water, contin...

Embodiment 2

[0043] 24g of methacrylic acid, 23g of hydroxyethyl acrylate and 18g of hydroxypropyl acrylate were dissolved in 50g of water to prepare solution A; 1.8g of thioglycolic acid and 0.8g of vitamin C were dissolved in 50g of water to prepare Solution B is obtained. Stir solution A and solution B evenly and pour them into the dropping tank.

[0044] Put 330g of water into the reactor and turn on the stirring mode, then put in 340g of methyl butenyl polyoxyethylene ether, conduct electric heating operation on the reactor, and control the temperature of the reactor within the range of 25-31°C; After the butenyl polyoxyethylene ether is completely dissolved, add 5g of hydrogen peroxide and stir for 5 minutes.

[0045] Add solution A and solution B dropwise to the reaction kettle at the same time, the duration of solution A is 2.5h, and the duration of solution B is 3.0h; after the addition is completed, continue to stir and keep warm for 2.0h, and then add to the reaction kettle Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com