Pneumatic wind-proof rail clamping device

A technology of windproof clip and windproof cover, which is applied in the directions of travel mechanism, load hanging element, transportation and packaging, etc., can solve the problems of high requirements on the license of hydraulic components, unsuitable for long-distance transmission of power, and complex structure of hydraulic rail clamps. , to achieve good clamping effect, simple structure, and reduce the effect of wind

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

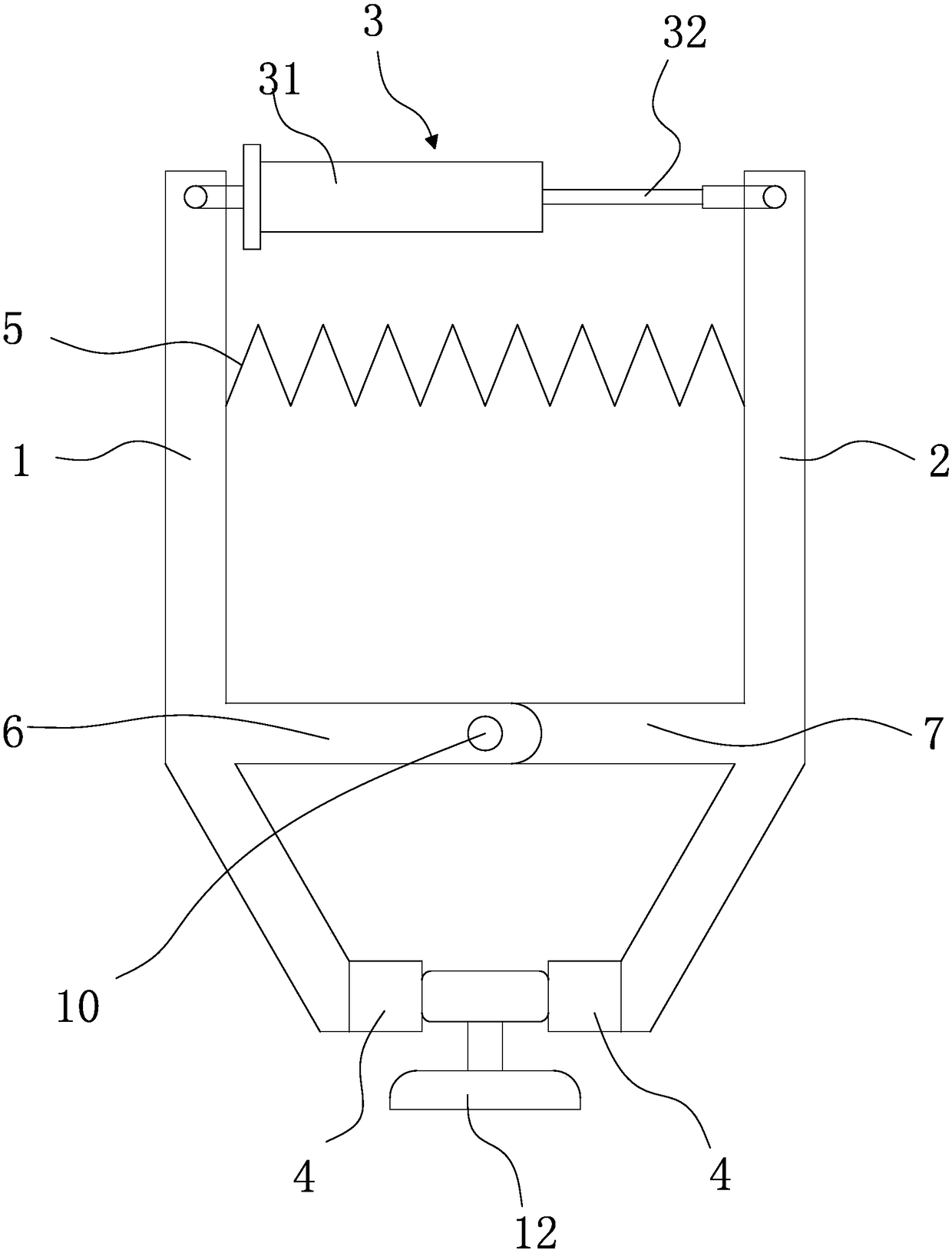

[0028] refer to figure 1 , the present embodiment is a pneumatic windproof rail clamp, which is characterized in that it includes a first clamp arm 1 and a second clamp arm 2 which are symmetrically arranged in pairs and can rotate with each other, the top end of the first clamp arm 1 and the There is a cylinder 3 between the top ends of the second clamp arm 2, the cylinder 3 includes a cylinder block 31 and a piston rod 32, the cylinder block 31 is connected to the first clamp arm 1, and the piston rod 32 is connected to the second clamp arm 2, the bottom end of the first clamp arm 1 and the bottom end of the second clamp arm 2 both have clamping parts 4, and a clamping spring is also arranged between the first clamp arm 1 and the second clamp arm 2 5. The middle part of the first clamp arm 1 has a hinged rod 1 extending toward the second clamping arm 2, and the middle part of the second clamping arm 2 has a hinged rod 2 extending toward the first clamping arm 1 side. 7. The...

Embodiment 2

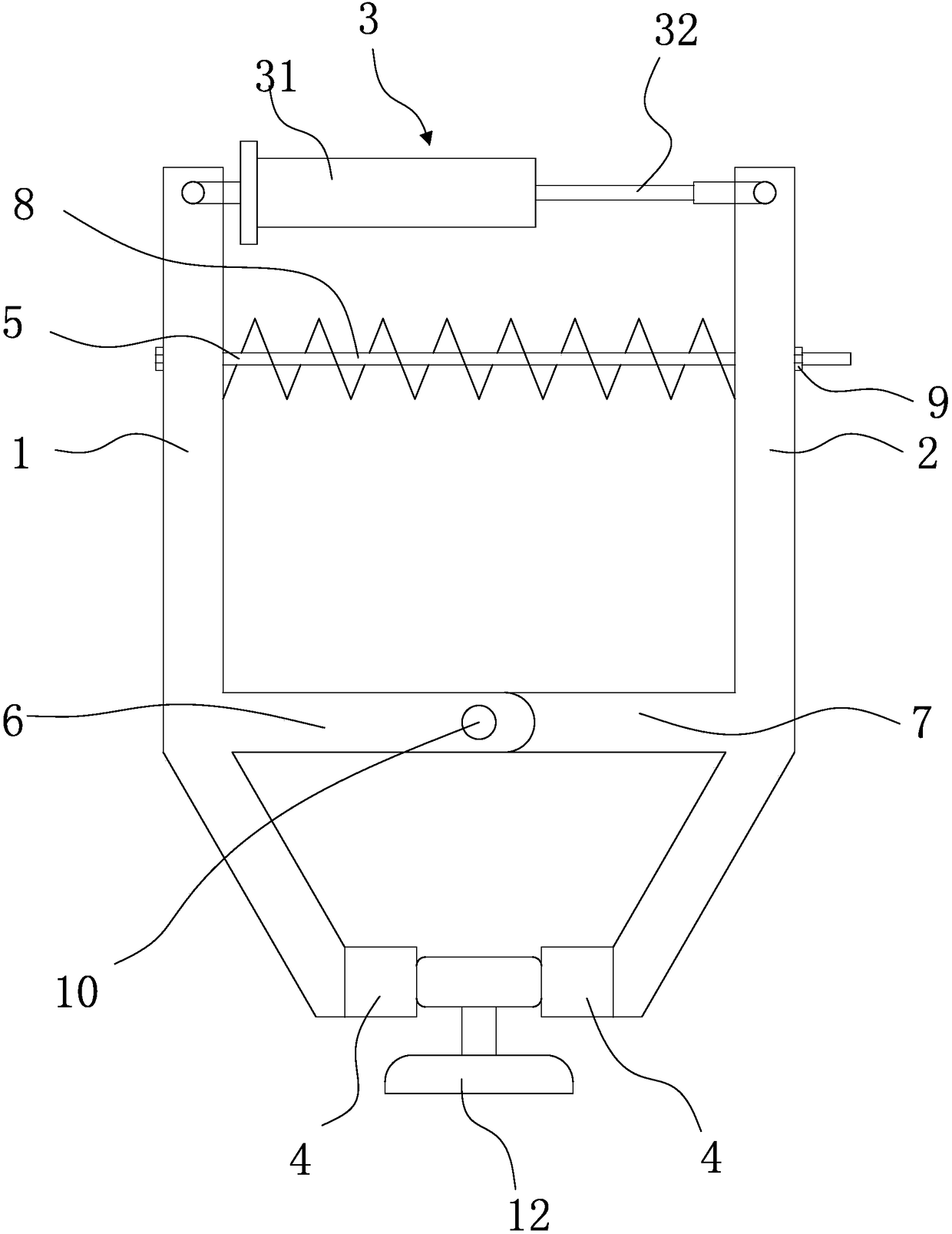

[0032] refer to figure 2 , the structure of the second embodiment is basically the same as that of the first embodiment, the difference is that a screw assembly is also provided between the first clamp arm 1 and the second clamp arm 2, and the screw assembly includes an adjusting screw 8 and an adjusting nut 9, The adjusting screw 8 is sequentially interspersed on the first clamp arm 1 and the second clamp arm 2, and the nut of the adjusting screw 8 abuts against the outer wall of the first clamp arm 1, and the adjusting nut 9 is threaded on the adjusting The end of the screw rod 8, and the adjustment nut 9 is against the outer wall of the second clamp arm 2, the clamping spring 5 is sleeved on the adjustment screw rod 8, and the clamping spring 5 and the adjustment screw rod 8 are coaxially arranged, and the adjustment More convenient, less adjustment resistance.

Embodiment 3

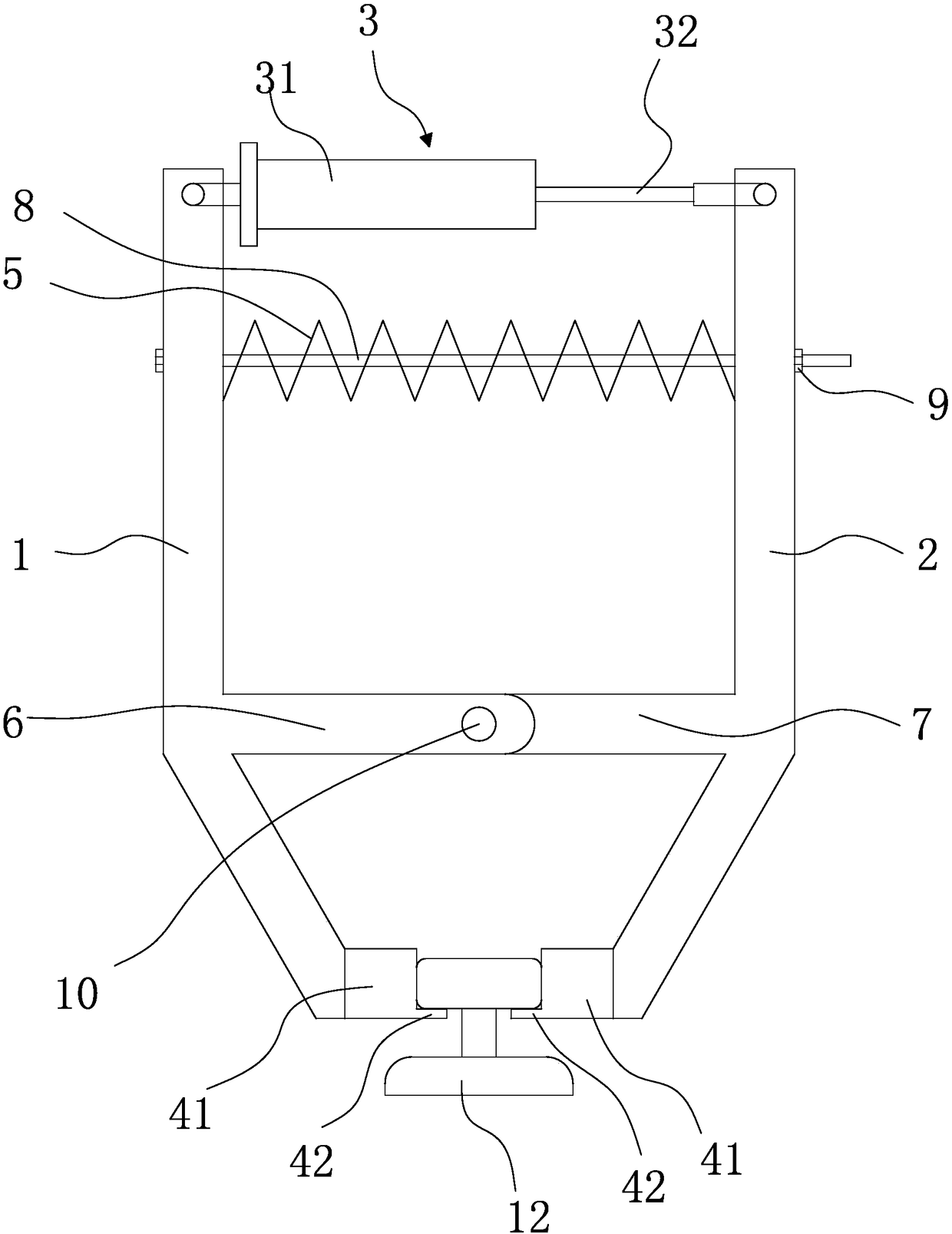

[0034] refer to image 3 , the structure of the third embodiment is basically the same as that of the second embodiment, the difference is that the clamping member 4 includes a vertical clamping portion 41 and a laterally disposed anti-off portion 42, and the anti-off portion 42 is connected to the clamping portion 41 bottom end. When the clamping part 4 clamps, the two clamping parts 41 are clamped on both sides of the upper layer of the I-steel track 12, and the anti-off part 42 is located between the upper and lower layers of the I-steel track 12. When the wind force is too large At this time, the top surface of the anti-falling part 42 can lean against the upper bottom surface of the I-beam rail 12, which not only avoids falling out, but also further increases the friction force, ensures stability, and avoids overturning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com