N, P and Si compound organic-inorganic composite ceramic peptizer

An inorganic composite and debonder technology, applied in the field of N, Si compound organic-inorganic composite ceramic debonder, P, which can solve the brittle cracking or shattering of ceramic products, low solubility of polyphosphate, and large thixotropy of ceramic mud, etc. problem, to achieve the effect of small loss of fluidity, enhanced degumming effect, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

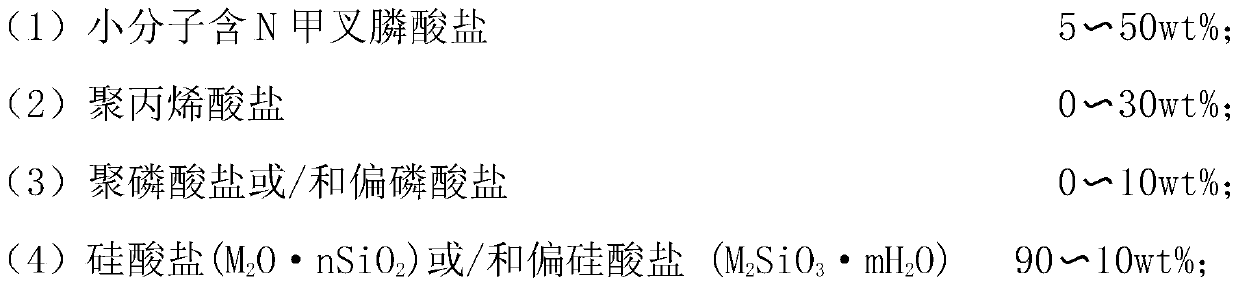

Method used

Image

Examples

Embodiment 1

[0038] Mix 15 parts by weight of sodium ethylenediamine tetramethylene phosphonate powder and 160.25 parts by weight of sodium metasilicate hexahydrate powder (85 parts by weight of sodium metasilicate) to obtain 175.25 parts by weight of solid organic-inorganic composite debonding agent . Then take a certain proportion, add it to a certain amount of water-containing ceramic slurry, grind for 10 minutes, measure the initial viscosity of the slurry and its fluidity change at room temperature 25°C, and sinter the slurry at a high temperature of 1200°C after molding to observe the product. Surface conditions, the results are listed in Table 1.

Embodiment 2

[0040]Mix 30 parts by weight of sodium aminotrimethylene phosphonate powder, 10 parts by weight of potassium tripolyphosphate, 120 parts by weight of potassium silicate water glass solution (the modulus is 2.5, and the concentration is 50wt%), and 240 parts by weight of water to obtain 400 parts by weight. A liquid organic-inorganic composite debonding agent with a content of 25 wt%. Then take a certain proportion, add it to a certain amount of water-containing ceramic slurry, grind for 10 minutes, measure the initial viscosity of the slurry and its fluidity change at room temperature 25°C, and sinter the slurry at a high temperature of 1200°C after molding to observe the product. Surface conditions, the results are listed in Table 1.

Embodiment 3

[0042] Mix 50 parts by weight of sodium diethylenetriaminepentamethylene phosphonate powder, 10 parts by weight of sodium tripolyphosphate, and 93.11 parts by weight of sodium metasilicate nonahydrate powder (40 parts by weight of sodium metasilicate) to obtain 153.11 parts by weight Solid organic-inorganic composite debonding agent. Then take a certain proportion, add it to a certain amount of water-containing ceramic slurry, grind for 10 minutes, measure the initial viscosity of the slurry and its fluidity change at room temperature 25°C, and sinter the slurry at a high temperature of 1200°C after molding to observe the product. Surface conditions, the results are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com