Shallow landslide control method combined with high pressure rotary jet piles and clustered miniature steel pipe piles

A technology for high-pressure rotary jetting piles and steel pipe piles, which is used in excavation, sheet pile walls, infrastructure projects, etc., and can solve problems such as high requirements for mechanical equipment construction sites, inability to implement landslide control projects, and large environmental and social impacts. , to achieve the effect of improving slope stability, high construction efficiency and saving construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

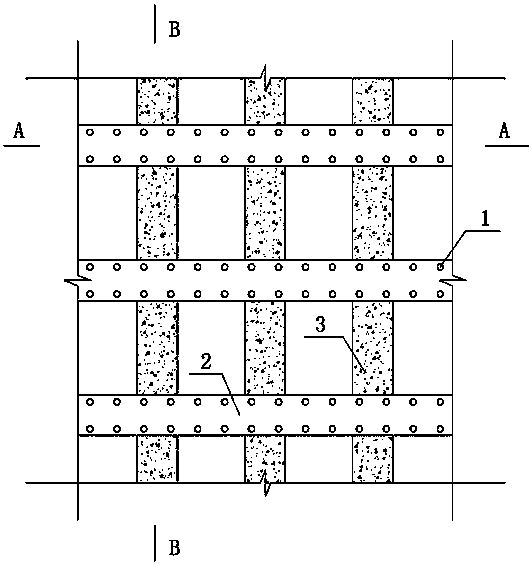

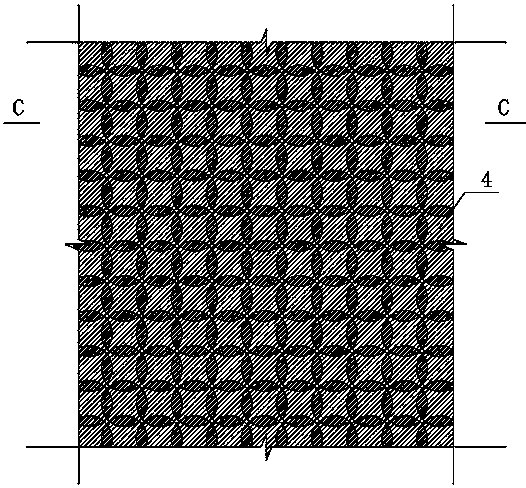

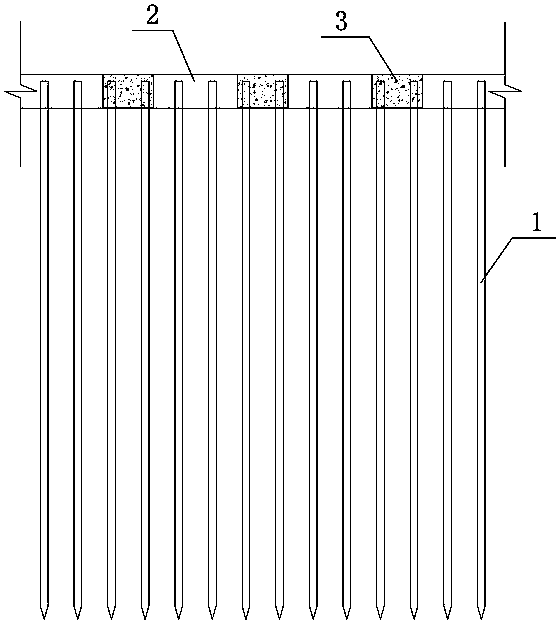

[0026] see Figure 1~9 , the present invention includes the construction of steel pipe piles 1, pile top crown beams 2, beams 3 and high-pressure jet grouting piles 4 on shallow landslides; Secondly, carry out the hole-forming construction of the steel pipe pile. After the hole-forming construction of the pile hole reaches the design elevation, insert the steel pipe pile with the hole, and then use cement slurry or cement mortar to grout the bottom of the hole to connect the outer wall of the steel pipe pile with the steel pipe pile. The gaps between the hole walls and the steel pipe piles are filled densely; finally, the crown beams and beams on top of the piles are constructed.

[0027] The steel pipe piles 1 form a row of piles every two or more rows, the steel pipe piles are arranged in a square or plum blossom shape, and a crown beam 2 is provided on the top of each row of piles, and the steel pipe piles in each row of piles 1 tops are all embedded in pile top crown beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com