Shearing type staged yield metal damper

A metal damper, a staged technology, applied to building components, shockproof, etc., can solve the problems that metal dampers cannot meet the energy consumption requirements of wind vibration, small earthquake and large earthquake at the same time, installation and maintenance are inconvenient, etc., and the production cost is low. , Easy installation, easy maintenance and replacement of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

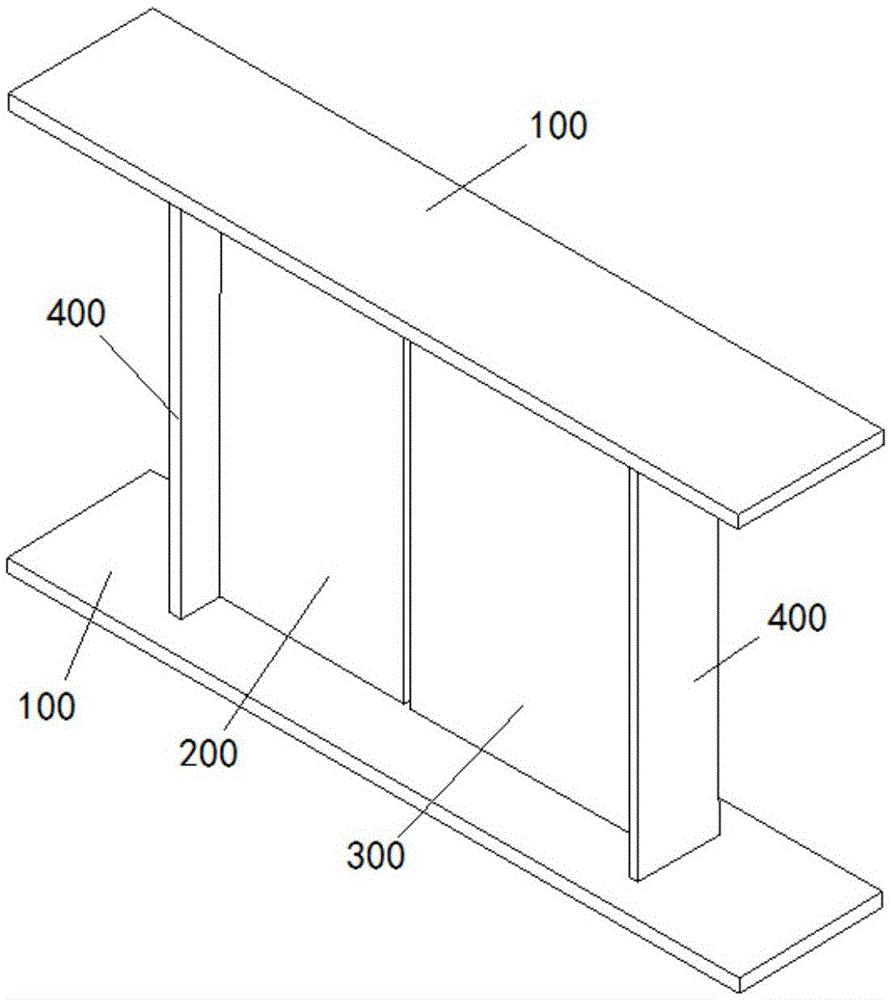

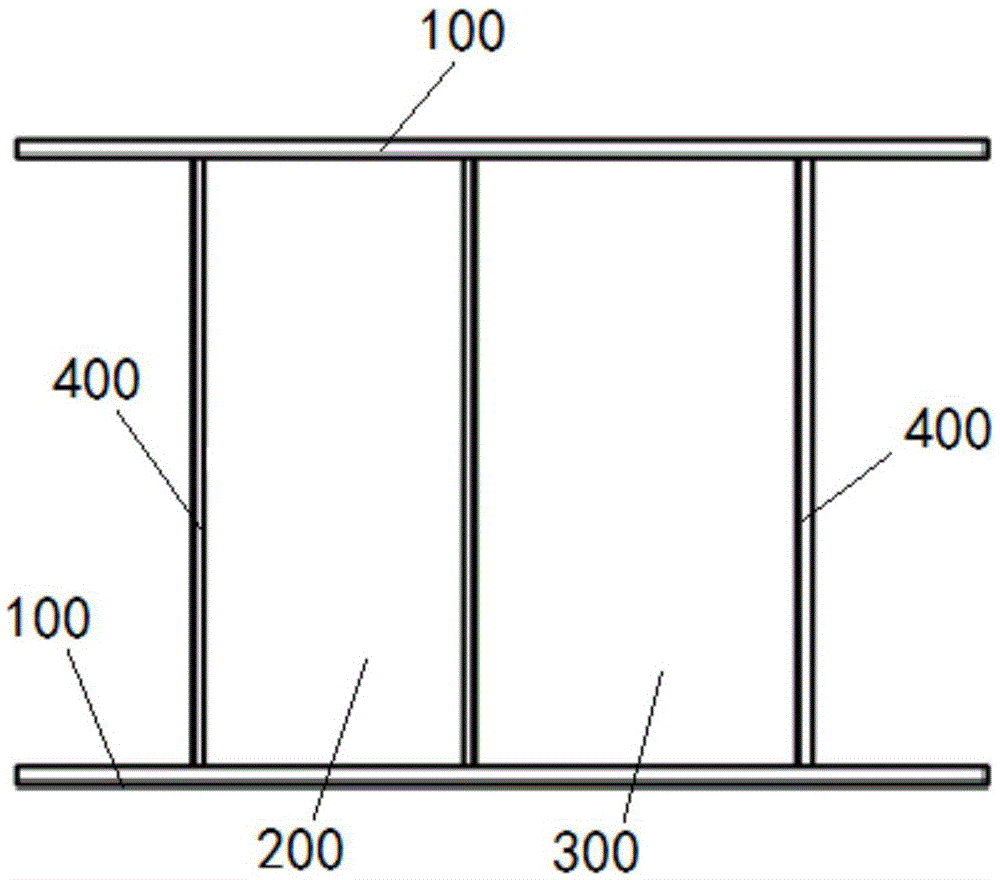

[0041] Without loss of generality, as Figure 1~2 As shown, the present invention provides a shear type staged yield metal damper, comprising: two steel flange plates 100 placed in parallel and a first rectangular rectangular plate fixed between the two steel flange plates The energy dissipation steel plate 200 and the second rectangular energy dissipation steel plate 300; the first rectangular energy dissipation steel plate 200 and the second rectangular energy dissipation steel plate 300 have different yield strengths; the two steel flange plates 100 are provided with The steel side panels 400 required by the first rectangular energy-dissipating steel plate 200 and the second rectangular energy-dissipating steel plate 300 are fixed.

[0042] Preferably, the present invention can realize the fast connection between the adjacent parts of the above-mentioned structure by welding.

[0043]The present invention adopts two rectangular energy-dissipating steel plates with differen...

Embodiment 2

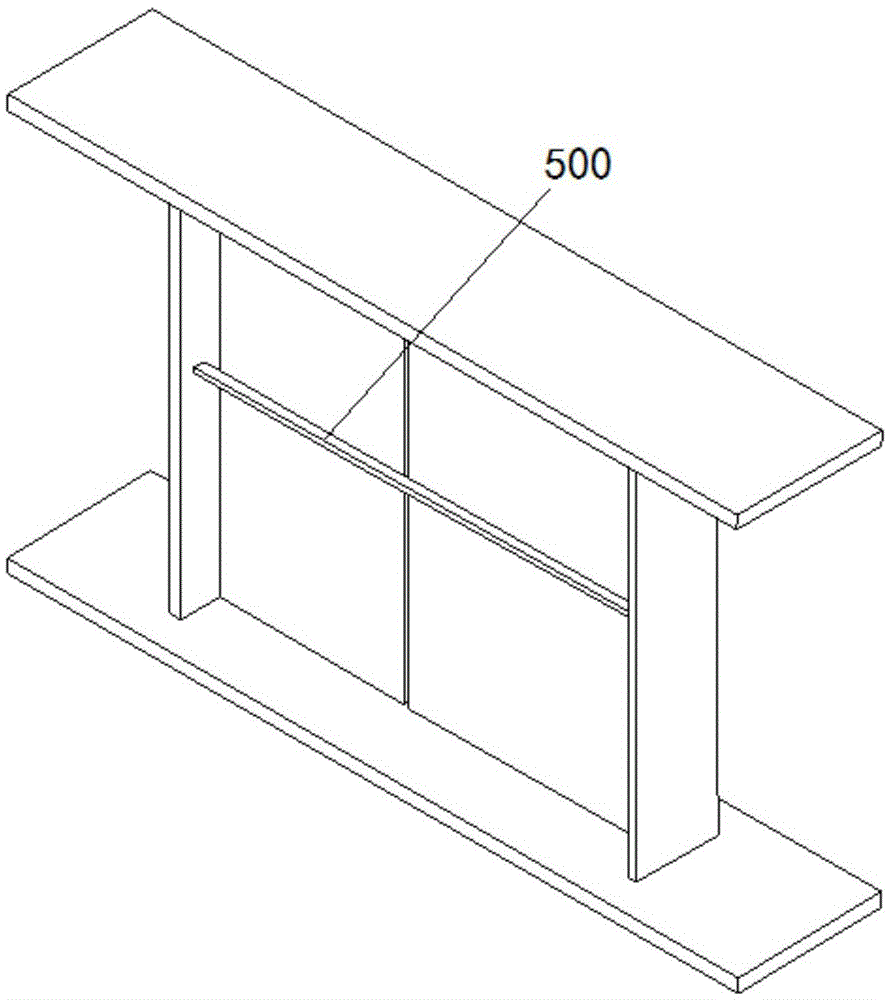

[0050] Such as Image 6 As shown, in this embodiment, on the basis of embodiment 1, in order to achieve the technical effect of longitudinal segmental yielding, the first rectangular energy-dissipating steel plate and the second rectangular energy-dissipating steel plate are placed up and down. Further expand the application occasions of the above-mentioned shear type step-by-step yield metal damper.

[0051] Further, such as Figure 7 As shown, in order to strengthen the fastening connection between the first rectangular energy-dissipating steel plate and the second rectangular energy- The solid connection of the second rectangular energy-dissipating steel plate provides a more stable structural support.

Embodiment 3

[0053] Such as Figure 8 As shown, in order to meet the requirement of staged energy dissipation, when the steel flange plate 100 is placed horizontally, the first rectangular energy dissipation steel plate 200 and the second rectangular energy dissipation steel plate 300 are placed back and forth. The application field of the above-mentioned shear type stepwise yield metal damper is further broadened.

[0054] It should be noted that since the firmness of fixing the first rectangular energy-dissipating steel plate and the second rectangular energy-dissipating steel plate by adding stiffeners has been involved in the foregoing embodiments, the technical means are not the core invention points of this embodiment. Therefore, in this embodiment, its related structure will not be illustrated and described in detail.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com